5

DANGER Warnings!

These warning refer to dangerous situations, which may result in serious accidents and be life

threatening, if the instructions are not strictly abided by.

CAUTION Warnings!

This type warns on dangerous situations and informs on necessary precautions in order to

avoid any possible accidents.

SAFETY PRECAUTIONS

- Read the instruction Manual before turning on the machine. Pay attention and abide by all

the recommendations for safely operating the equipment. SHARE THIS INFORMATION

WITHALLOTHER USERS.

- Do not operate the machine while or after drinking alcoholic beverages or medications which

affect your normal condition. Pay attention to what you are doing and use your good sense.

Any lack of attention while operating the machine can result in a serious accident.

TECHNICAL MANUAL OF OPERATION - JF 15D

Environmental conservation

Safety

JF Máquinas is continually concerned with the environmental conservation, in the

development phase, as well in the utilization of processes and materials ecologically

appropriate in its production and its products.

PROTECT AND RESPECT THE ENVIRONMENT, remember that conservation is the social

responsibility of everyone. These concepts include compliance with legally defined disposal

of used lubrication products and fluids, old tires, and packaging. Never dispose of these

products or empty packaging in swamplands, lakes, rivers, puddles etc. Share these

recommendations with others and make other people aware of the importance of conserving

the environment.

The JF Máquinas is concerned about the safety of people involved in operating and

performing maintenance procedures on the machine. In developing this design, we have

considered every detail in order to avoid unexpected accidents while operating it.

We have developed safety shielding and eliminated dangerous situations. Remember,

keeping people healthy and their physical integrity must always be considered to the upmost.

We have prepared this manual to make you familiar with your machine and, so that you can

use it correctly and safety.

We recommend carefully reading it before operating the machine the first time. If you have any

doubts or questions, please get In touch with us at your JF Máquinas reseller or our technical

support department.

Safety Warnings

Safety warnings alert on situations that can be dangerous in some away.

They are accompanied by instructions for protecting the operator and other

users.

English

26

Guía práctico

Debido al exceso de

alimentación, el motor no

consigue mantener la

rotación necesaria y el

producto se acumula

dentro de la máquina

Parar el motor, limpiar el exceso de

producto, arrancar nuevamente y

controlar la alimentación de la

máquina de manera que no exija

más que la capacidad indicada.

1- Alimentación insuficiente

de la máquina

1- La alimentación debe ser

continua, aunque no en exceso,

pues puede causar trabado

2- Rotación de la máquina

debajo de la indicada

2- Si la rotación de la máquina

estuviere debajo de la indicada, los

martillos tardarán más para triturar

el producto y con eso, caerá la

producción. Por tanto, se debe

mantener la rotación indicada para

la máquina

3- Si los productos estuvieren muy

húmedos, los orificios de los filtros

podrán quedar bloqueados. Por

tanto, se deben triturar solo

productos secos

4- Regulado de la máquina

incompatible con el

producto a ser obtenido

4- Se debe verificar si el filtro

usado es compatible con el

producto a ser obtenido

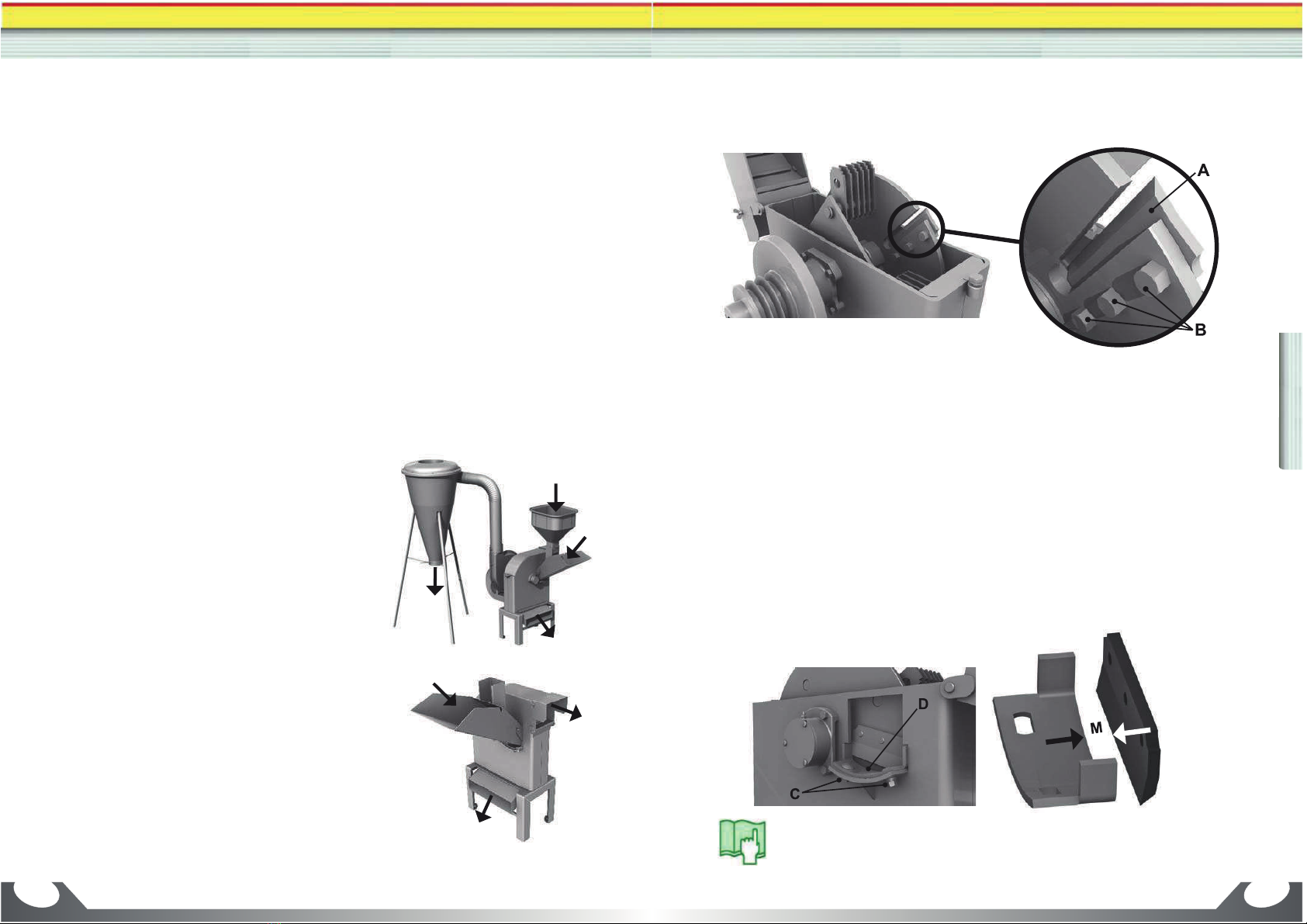

Corte irregular del

producto

1- Falta de filo en las

cuchillas

1- Afilar nuevamente las cuchillas

conforme indicado en el item

“Afilado de las cuchillas”

2- Contracuchilla gastada o

desregulada

2- Seguir el indicado en el ítem

“Regulado de la contracuchilla”

Deficiencia al moler

productos secos

1- Martillos gastados o

dañados

1- Cambiar los lados de los

martillos o por nuevos, procediendo

conforme indicado en el item

“cambio de martillos”

2- Lavar los picos, cuchillas y martillos,

con agua después de picar productos

verdes principalmente antes de

paradas prolongadas

Dificuldad de

arranque del

accionamiento

Exceso de producto dentro

de la máquina

Al terminar el trabajo, dejar a

máquina en funcionamiento, hasta

la salida completa del producto