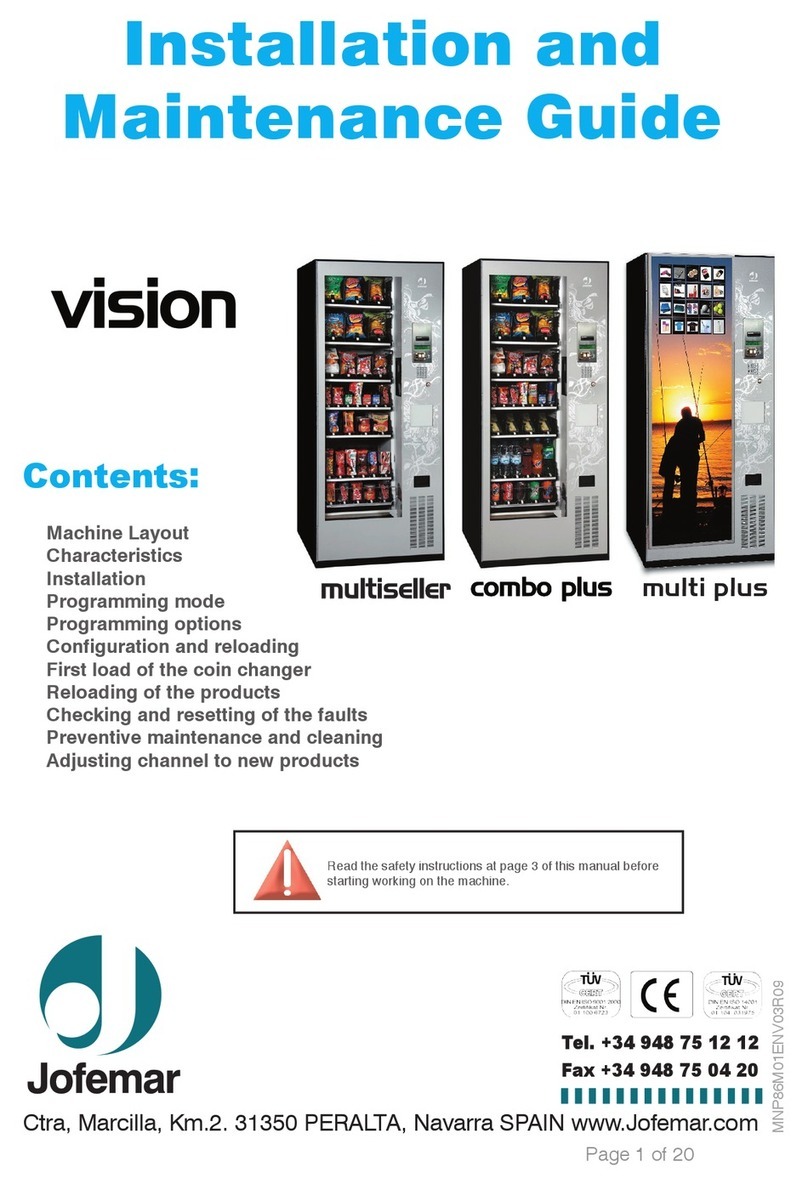

vision

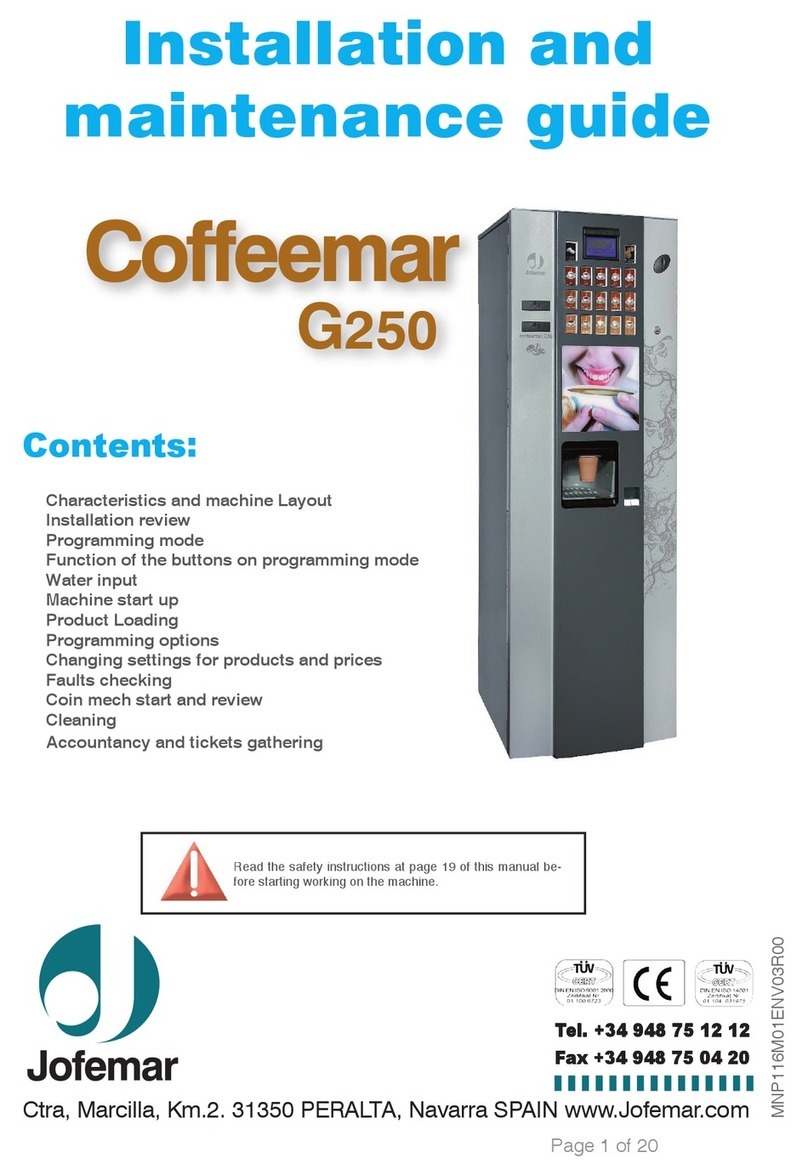

Snack Plus/Easy Combo

//

Vending

MNP86V03GBV00 Date: 2010/06/14 Rev. 0 PAGE 3 OF 62

TABLE OF CONTENTS

1. Symbo s...................................................................................................................... 4

2. Operating conditions................................................................................................... 4

3. Description of components.......................................................................................... 4

3.1. Main technica features....................................................................................... 5

3.1.1. Door ......................................................................................................... 6

3.1.2. Cabinet..................................................................................................... 9

3.2. Vo ume and weight ........................................................................................... 14

4. E ectric-e ectronic specifications ........................................................................... 15

4.1. Initia e ectrica insta ation ............................................................................ 15

4.2. Product dispenser channe ............................................................................... 15

4.3. Disp ay card...................................................................................................... 16

4.4. Contro card...................................................................................................... 16

4.5. Re ay card ........................................................................................................ 17

4.6. Photodiode and phototransistor cards............................................................... 17

4.7. E ectronic thermometer card............................................................................. 18

4.8. Modem communications interface card............................................................. 19

4.9. R 134A CFC-free coo ing unit ........................................................................... 19

4.10. E ectronic contro system ................................................................................ 19

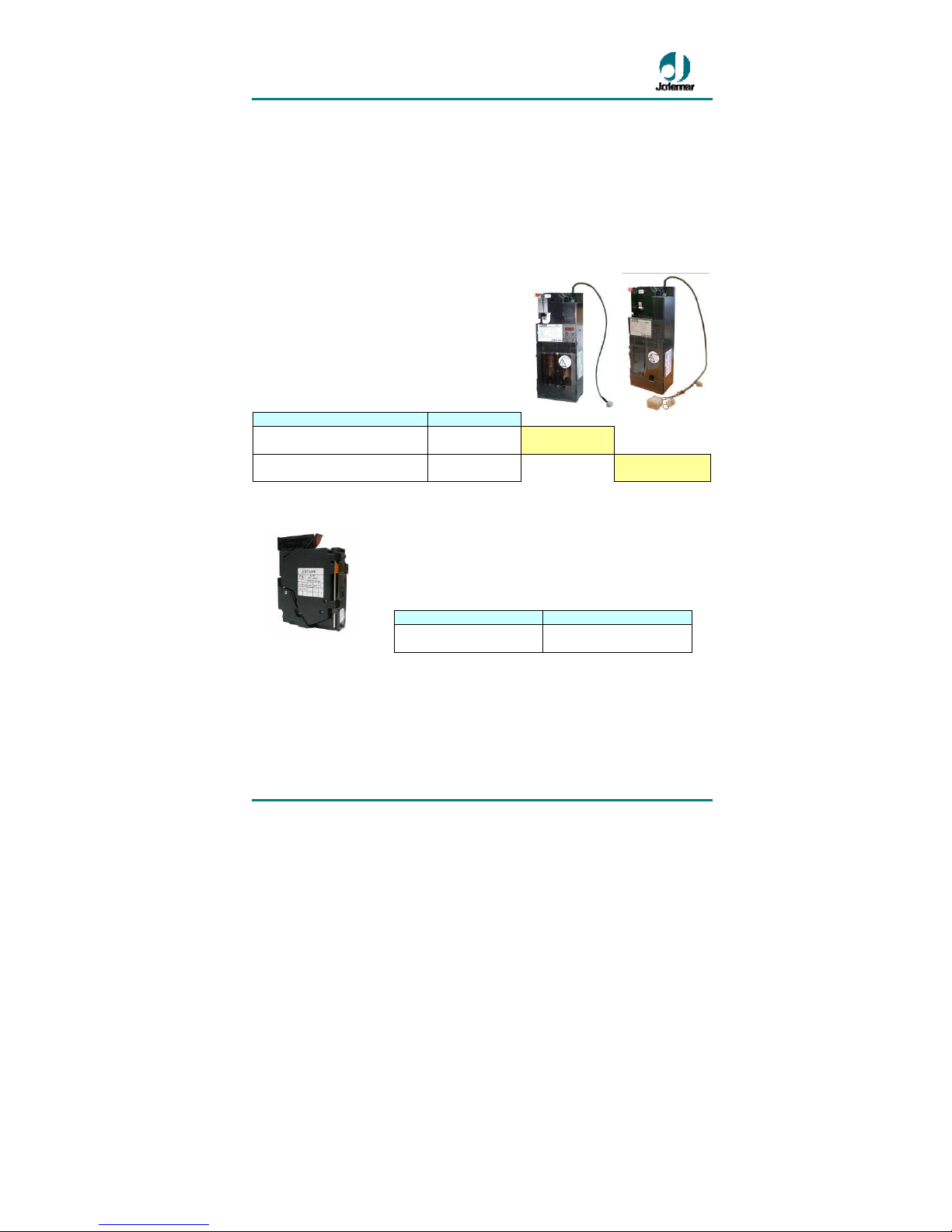

4.11. T-15 va idator (se ector) .................................................................................. 20

4.12. Compact J-2000 ............................................................................................. 20

4.12.1. Coin separator...................................................................................... 21

4.12.2. Return carriage..................................................................................... 21

4.13. Recovery motor .............................................................................................. 21

4.14. BT-10 banknote reader................................................................................... 22

4.15. E ectrica diagram ........................................................................................... 23

5. Insta ation and start up............................................................................................. 24

5.1. Insta ation ........................................................................................................ 24

5.2. Start up............................................................................................................. 24

5.3. Memory reset.................................................................................................... 24

5.4. Restocking machine trays................................................................................. 25

5.5. Product se ection .............................................................................................. 25

5.6. Updating the machine program......................................................................... 26

5.7. Machine programming mode ............................................................................ 27

5.7.1. Standby menu without credit (standby status)......................................... 27

5.7.2. Standby menu with credit (working status).............................................. 28

5.7.3. Programming menu (programming status).............................................. 28

5.8. Programming addresses................................................................................... 30

6. Troub eshooting ........................................................................................................ 52

7. Annexes.................................................................................................................... 55

7.1. Periphera s ....................................................................................................... 55

7.2. Jams and changes in the J-2000 compact tubes............................................... 57

7.3. Insta ing and removing channe s ...................................................................... 57

7.4. Transport feet and adjustab e eve ing feet....................................................... 58

7.5. C eaning and Maintenance ............................................................................... 59

7.6. Recyc ing.......................................................................................................... 60

7.7. Environment ..................................................................................................... 60

8. Regu ation ................................................................................................................ 61