MNP116M01GBV00 Date: 09/04/2013 Rev. 1 PAGE 3 OF 95

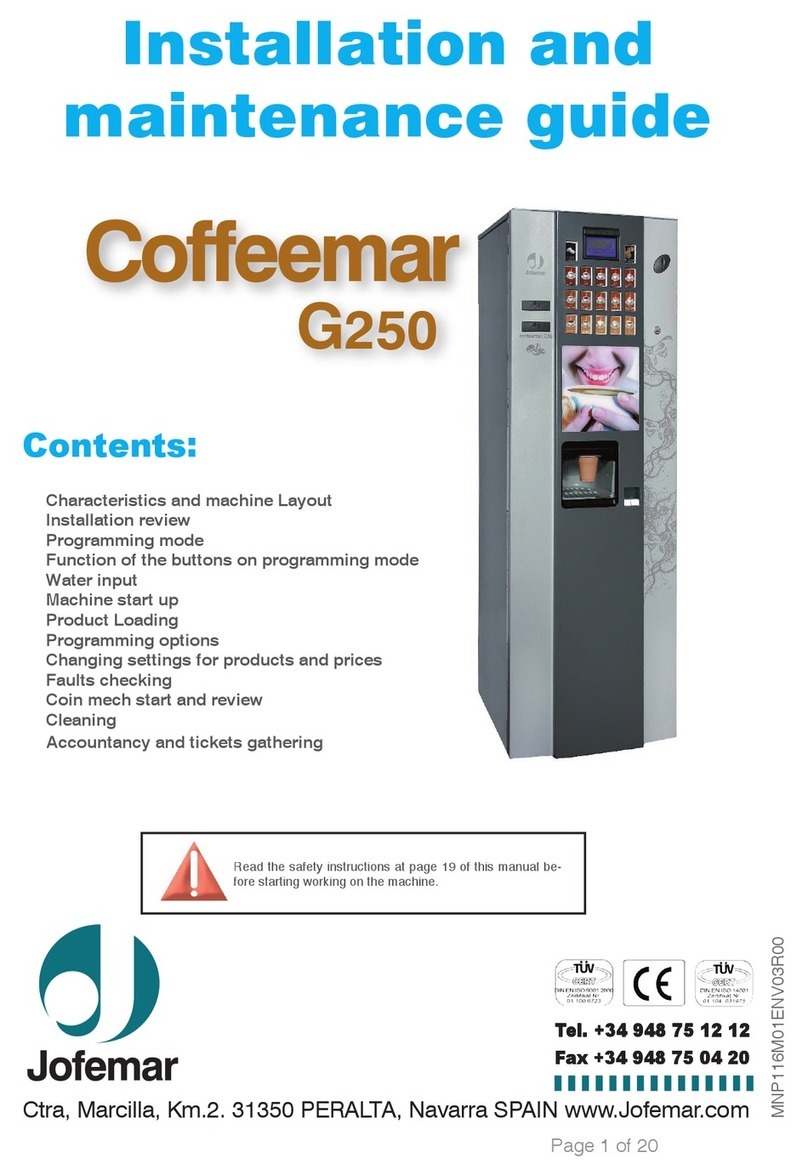

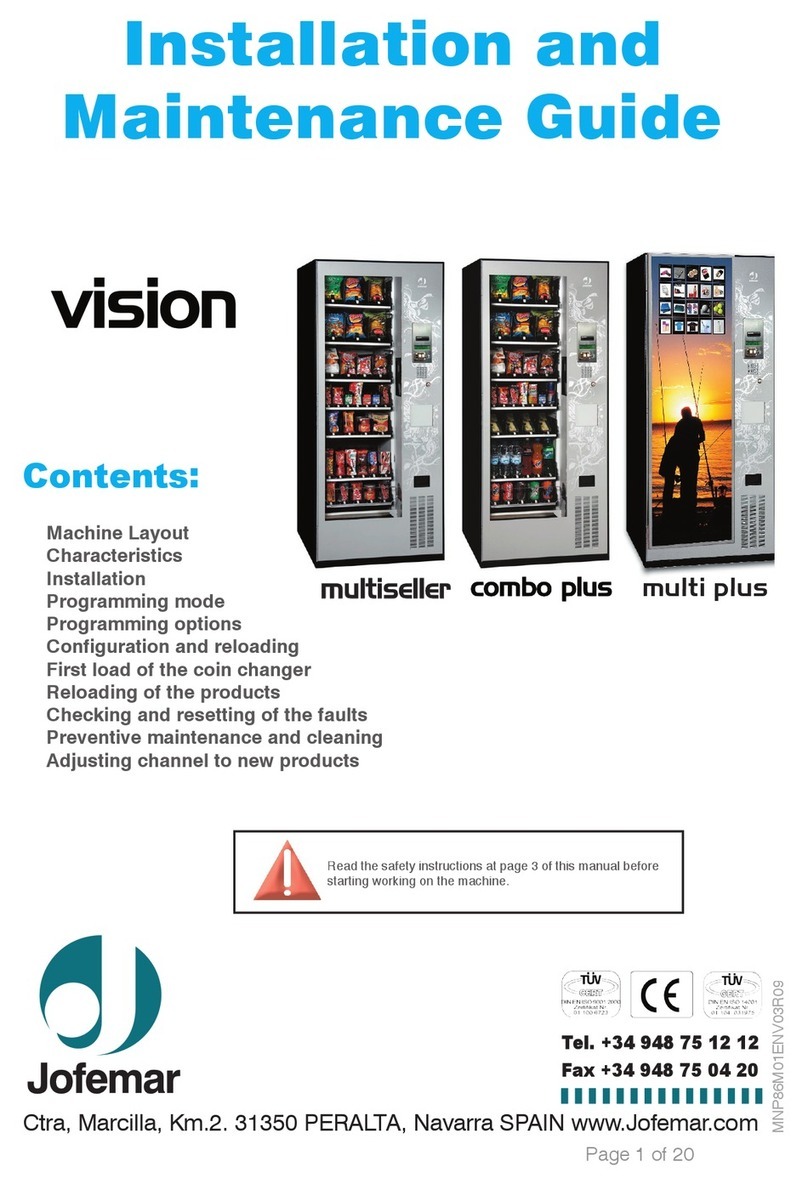

TABLE OF CONTENTS

1. Symbols .................................................................................................................... 4

2. Operat ng cond t ons .................................................................................................. 4

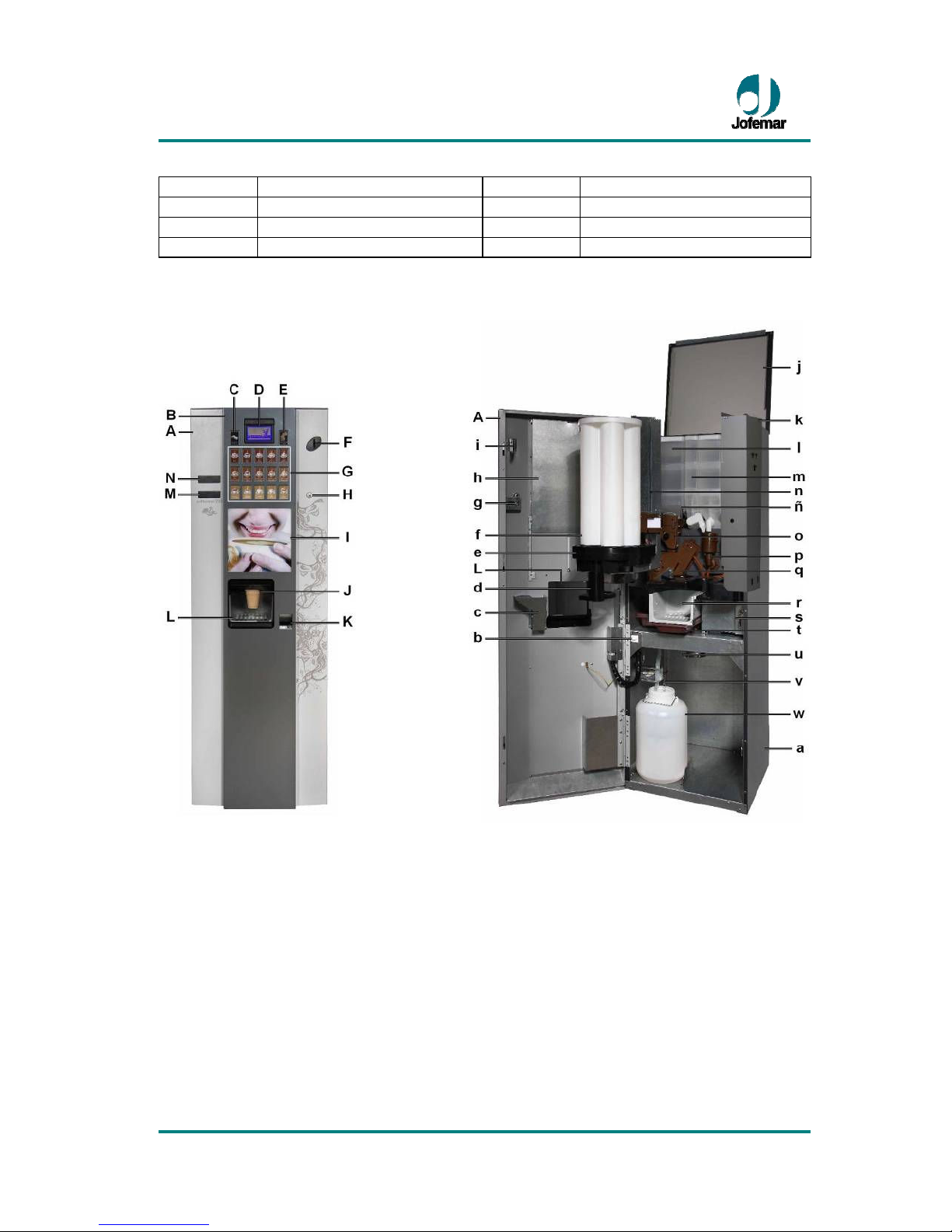

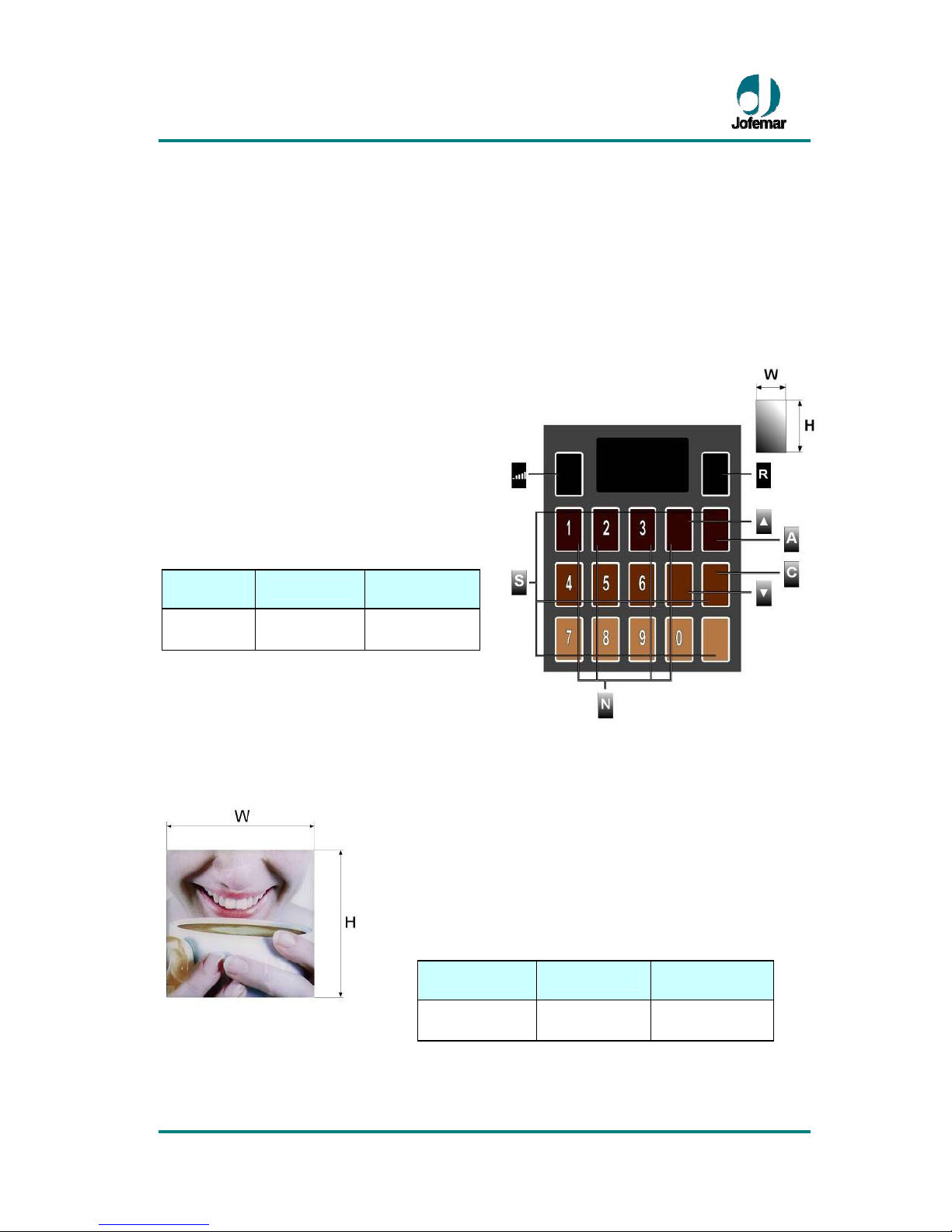

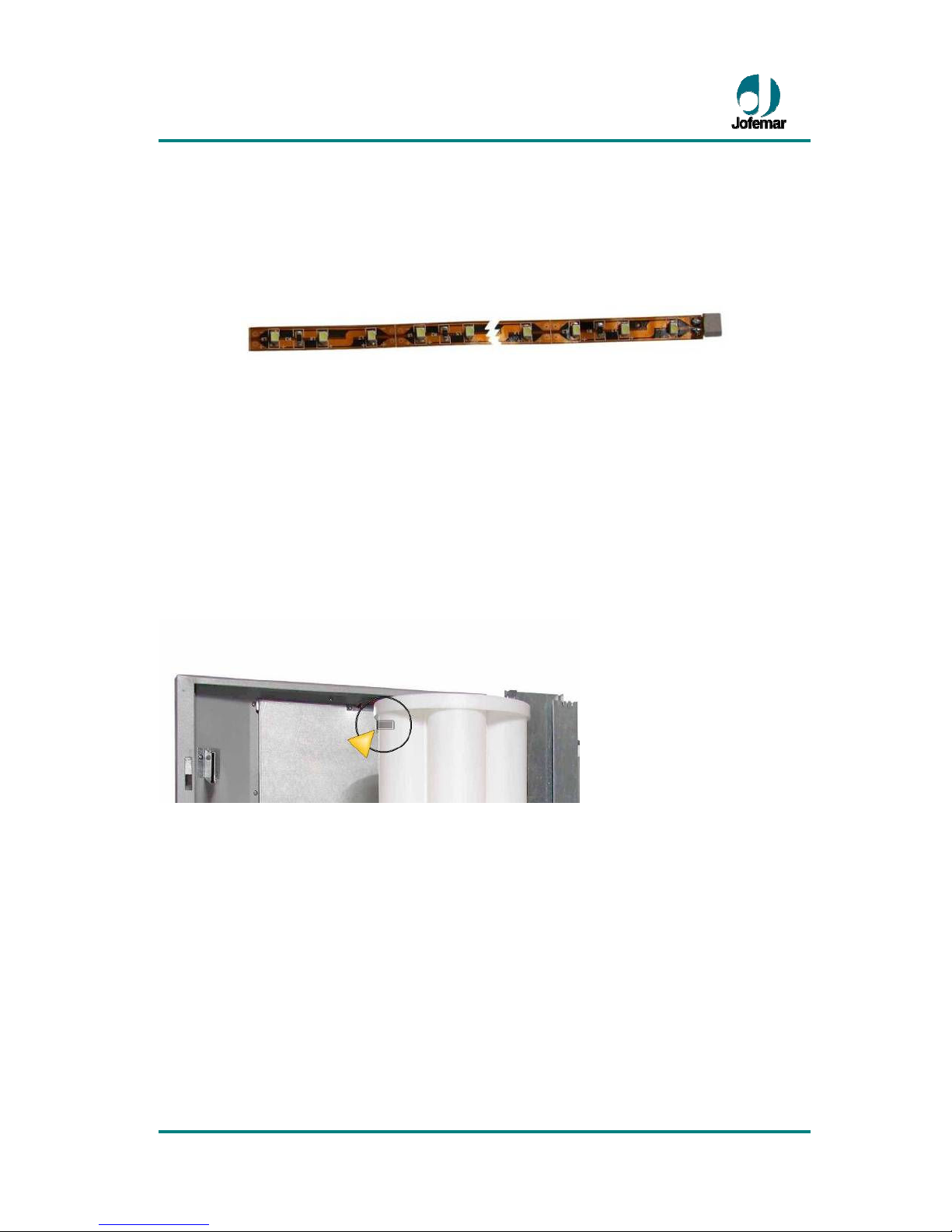

3. Descr pt on of components ........................................................................................ 4

3.1. Ma n techn cal features...................................................................................... 5

3.1.1. Door .......................................................................................................... 6

3.1.2 Cab net ...................................................................................................... 8

3.2. Volume and we ght .................................................................................... 27

4. Electr cal and electron c spec f cat ons ................................................................ 28

4.1. In t al electr cal nstallat on ........................................................................... 29

4.2. D splay card .................................................................................................... 29

4.3. Control card .................................................................................................... 31

4.4. Electron cs assembly ....................................................................................... 32

4.5. Val dator (selector) .......................................................................................... 33

4.6. Compact (MDB) .............................................................................................. 33

4.7. Recovery motor ............................................................................................... 34

4.8. Electr cal draw ng ............................................................................................ 35

4.9. Water c rcu t .................................................................................................... 36

5. Installat on and start-up. .......................................................................................... 37

5.1. Installat on ....................................................................................................... 37

5.2. Connect on to ma ns ................................................................................... 37

5.3. Connect on to water ma ns .............................................................................. 38

5.4. F ll ng the water c rcu t ..................................................................................... 39

5.5. Cup load ng ..................................................................................................... 40

5.6. St r-st ck load ng .............................................................................................. 41

5.7. Start-up ........................................................................................................... 43

5.8. Insert ng product cards .................................................................................... 43

5.9. Load ng soluble products ................................................................................. 43

5.10. Product select on ........................................................................................... 44

5.11. Updat ng the mach ne program ..................................................................... 45

5.12. Mach ne reset ................................................................................................ 46

5.13. Mach ne programm ng mode ......................................................................... 47

5.13.1. Standby menu w thout cred t (standby status) ....................................... 47

5.13.2. Standby menu w th cred t (work ng status) ............................................ 48

5.13.3. Programm ng menu (programm ng status) ........................................ 48

5.14. Programm ng addresses (Ma n Menu) ........................................................... 49

7. Annexes ................................................................................................................. 81

7.1. Per pherals (Opt ons ) ..................................................................................... 81

8. Clean ng and Ma ntenance ...................................................................................... 87

9. Recycl ng ................................................................................................................. 93

10. Env ronment

.......................................................................................... 93

11. Regulat ons ........................................................................................................... 93