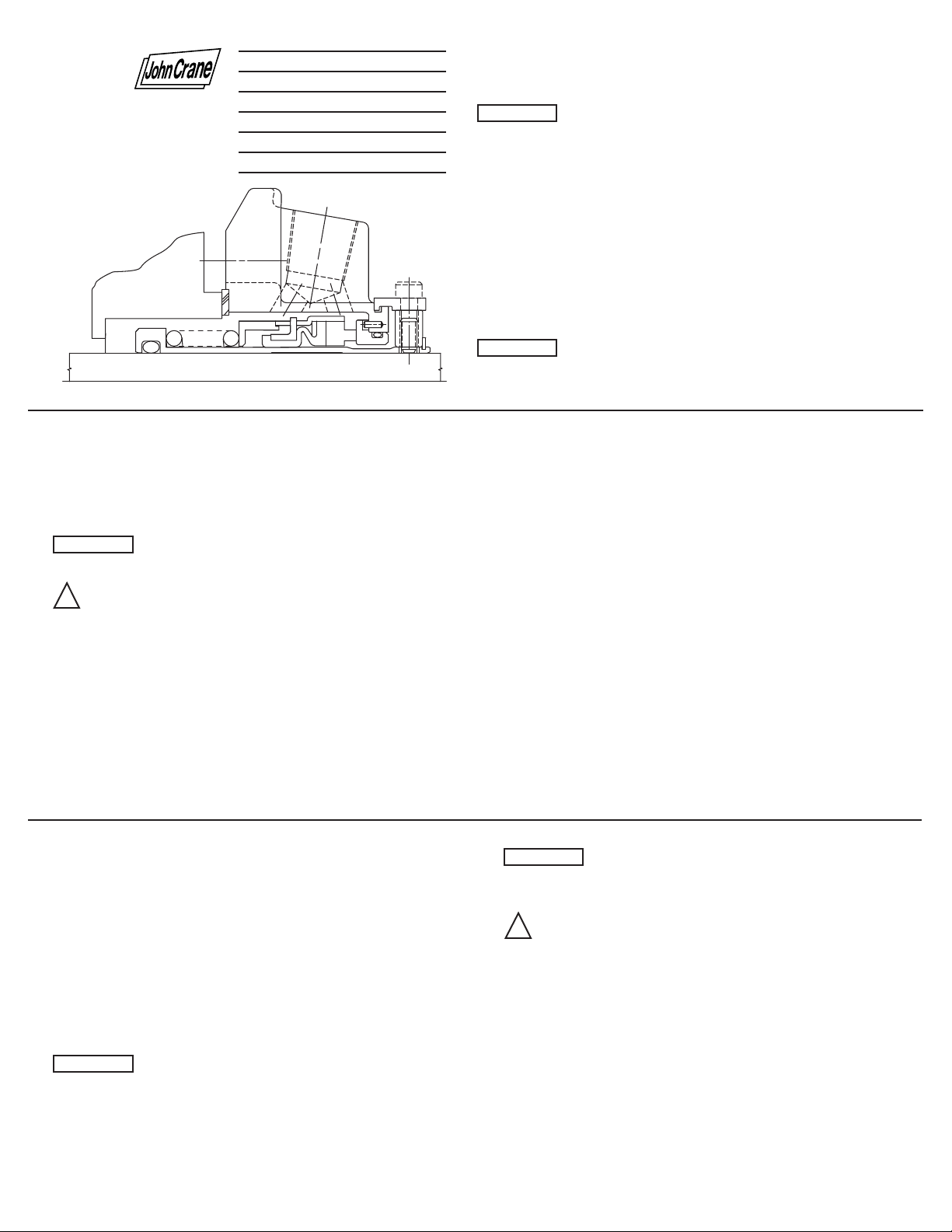

Type 5611 Cartridge Dimensional Data (inches)

Seal Size D4

D1 D3 Min. Max. D26 L12 L23 L39 L56 L90 L91 L92 MN

1.000 1.375 1.500 1.889 4.000 2.739 1.353 1.954 0.531 2.000 0.910 0.785 0.525 2.805

1.125 1.500 1.625 2.015 4.125 2.595 1.446 2.062 0.531 2.125 0.685 0.533 0.525 2.933

1.250 1.687 1.812 2.294 4.250 2.718 1.446 2.062 0.531 2.125 0.781 0.656 0.525 3.213

1.375 1.812 1.937 2.421 4.375 2.625 1.446 2.062 0.531 2.125 0.688 0.563 0.525 3.338

1.500 2.000 2.125 2.680 4.875 2.960 1.487 2.125 0.593 2.187 0.960 0.835 0.525 3.599

1.625 2.125 2.250 2.812 5.000 3.022 1.487 2.125 0.593 2.187 1.022 0.897 0.562 3.766

1.750 2.250 2.375 2.918 5.250 3.038 1.487 2.125 0.593 2.187 1.038 0.913 0.562 3.875

1.875 2.375 2.500 2.918 5.250 3.038 1.487 2.125 0.593 2.187 1.038 0.913 0.562 3.875

2.000 2.687 2.750 3.015 5.500 3.454 1.601 2.312 1.063 2.375 1.266 1.141 0.562 4.000

2.125 2.812 2.875 3.360 5.859 3.454 1.601 2.312 0.593 2.375 1.266 1.141 0.687 4.469

2.250 2.750 2.875 3.485 6.500 3.579 1.601 2.312 0.593 2.375 1.391 1.266 0.687 4.566

2.375 3.062 3.125 3.610 6.500 3.468 1.717 2.466 0.625 2.528 1.127 1.002 0.687 4.719

2.500 3.250 3.375 3.891 6.750 3.892 1.717 2.563 0.625 2.625 1.391 1.266 0.687 5.000

2.625 3.500 3.625 4.062 6.750 3.978 1.625 2.500 0.625 2.562 1.603 1.478 0.687 5.170

2.750 3.500 3.625 4.062 6.750 3.978 1.625 2.500 0.625 2.562 1.603 1.478 0.687 5.170

2.875 3.625 3.695 4.186 7.000 3.978 1.725 2.500 0.625 2.562 1.603 1.478 0.687 5.312

3.000 3.937 4.000 4.469 7.750 4.172 1.787 2.562 0.685 2.625 1.735 1.610 0.812 5.720

3.125 4.062 4.125 4.600 7.875 4.187 1.593 2.562 - 2.687 1.750 1.625 0.812 5.845

3.250 4.062 4.125 4.600 7.437 4.187 1.593 2.510 - 2.635 1.802 1.677 0.812 5.845

3.375 4.312 4.375 4.850 8.125 4.375 1.593 2.562 - 2.687 1.938 1.813 0.812 6.095

3.500 4.437 4.500 4.975 8.250 4.344 1.593 2.562 - 2.687 1.907 1.782 0.812 6.220

3.625 4.562 4.625 5.100 8.375 4.625 1.593 2.562 - 2.687 2.188 2.063 0.687 6.250

3.750 4.632 4.724 5.199 8.750 4.437 1.593 2.562 - 2.687 2.000 1.875 0.687 6.770

3.875 4.812 4.905 5.375 8.750 4.500 1.593 2.562 - 2.687 2.063 1.938 0.812 6.636

4.000 4.937 5.031 5.500 9.000 4.812 1.593 2.562 - 2.687 2.375 2.250 0.812 6.761

5.000 6.500 6.593 7.260 12.000 5.750 1.749 3.043 - 3.168 2.832 2.707 0.812 10.000

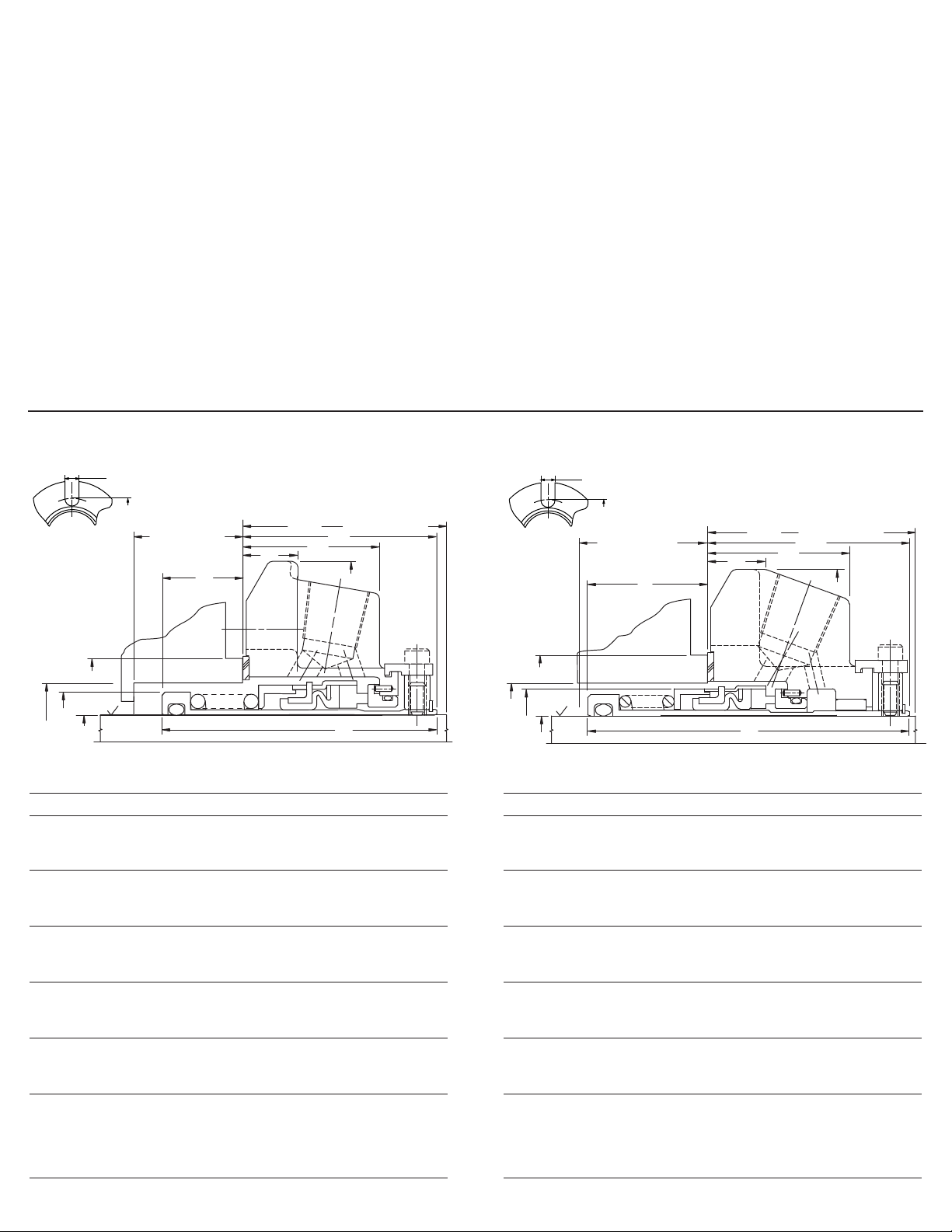

Type 5611Q Cartridge Dimensional Data (inches)

Seal Size D4

D1 D3 Min. Max. D26 L12 L23 L39 L56 L90 L91 L92 MN

1.000 1.562 1.625 1.889 4.000 3.327 1.353 1.954 0.531 2.000 1.498 1.373 0.525 2.805

1.125 1.687 1.750 2.015 4.125 3.183 1.446 2.062 0.531 2.125 1.246 1.121 0.525 2.933

1.250 1.812 1.875 2.294 4.250 3.390 1.446 2.062 0.531 2.125 1.453 1.328 0.525 3.213

1.375 1.936 2.000 2.421 4.375 3.290 1.446 2.062 0.531 2.125 1.353 1.228 0.525 3.338

1.500 2.156 2.218 2.680 4.875 3.548 1.487 2.125 0.593 2.187 1.548 1.423 0.525 3.599

1.625 2.281 2.343 2.812 5.000 3.610 1.487 2.125 0.593 2.187 1.610 1.485 0.562 3.766

1.750 2.406 2.480 2.918 5.250 3.626 1.487 2.125 0.593 2.187 1.626 1.501 0.562 3.875

1.875 2.531 2.625 2.918 5.250 3.626 1.487 2.125 0.593 2.187 1.626 1.501 0.562 3.875

2.000 2.687 2.750 3.015 5.500 4.042 1.601 2.312 1.063 2.375 1.854 1.729 0.562 4.000

2.125 2.812 2.875 3.360 5.859 4.042 1.601 2.312 0.593 2.375 1.854 1.729 0.687 4.469

2.250 2.937 3.000 3.485 6.500 4.167 1.601 2.312 0.593 2.375 1.979 1.854 0.687 4.566

2.375 3.062 3.125 3.610 6.500 4.062 1.717 2.466 0.625 2.528 1.783 1.596 0.687 4.719

2.500 3.250 3.375 3.891 6.750 4.325 1.717 2.563 0.625 2.625 1.887 1.762 0.687 5.000

2.625 3.500 3.625 4.062 6.750 4.566 1.625 2.500 0.625 2.562 2.191 2.066 0.687 5.170

2.750 3.500 3.625 4.062 6.750 4.566 1.625 2.500 0.625 2.562 2.191 2.066 0.687 5.170

2.875 3.625 3.695 4.186 7.000 4.578 1.725 2.500 0.625 2.562 2.203 2.078 0.687 5.312

3.000 3.937 4.000 4.469 7.750 4.750 1.787 2.562 0.685 2.625 2.313 2.188 0.812 5.720

3.125 4.062 4.125 4.600 7.875 4.781 1.593 2.562 - 2.687 2.344 2.219 0.812 5.845

3.250 4.062 4.125 4.600 7.437 4.781 1.593 2.510 - 2.635 2.333 2.208 0.812 5.845

3.375 4.312 4.375 4.850 8.125 4.969 1.593 2.562 - 2.687 2.532 2.407 0.812 6.095

3.500 4.437 4.500 4.975 8.250 4.969 1.593 2.562 - 2.687 2.532 2.407 0.812 6.220

3.625 4.562 4.625 5.100 8.375 5.218 1.593 2.562 - 2.687 2.781 2.656 0.687 6.250

3.750 4.687 4.781 5.199 8.750 5.031 1.593 2.562 - 2.687 2.594 2.469 0.687 6.770

3.875 4.875 4.968 5.375 8.750 5.093 1.593 2.562 - 2.687 2.656 2.531 0.812 6.636

4.000 5.021 5.114 5.500 9.000 5.406 1.593 2.562 - 2.687 2.969 2.844 0.812 6.761

5.000 6.500 6.593 7.260 12.000 6.406 1.749 3.043 - 3.168 3.488 3.363 0.812 10.000

63

L12

L23

L39L91 MIN. BOX DEPTH

L92

L90 MIN. NEAREST OBSTRUCTION

D26

L56

D4

*MIN. TURN DIAM.

D1

D3

SLOT

WIDTH

M

N

.040"

For ease of installation

of the Type 5611, the lead-in

edge of the shaft or sleeve

should be chamfered

as shown above.

20˚

Type 5611 Installation Dimensions Type 5611Q Installation Dimensions

L23

L39

L91 MIN. BOX DEPTH

L92

D1 +.000"

-.002"

L90 MIN. NEAREST OBSTRUCTION

D26

D3

L56

L12

*MIN. TURN DIAM.

D4

63

SLOT

WIDTH

M

N

.040"

For ease of installation

of the Type 5611, the lead-in

edge of the shaft or sleeve

should be chamfered

as shown above.

20˚

6. Set the gland plate assembly gasket side down on table. Install collar on

gland plate assembly and engage spacers into groove, aligning spacers

with pipe taps of gland plate. Uniformly finger tighten the cap screws.

This sets the radial spacing of the cartridge.

7. Install disc into the retainer, rotating the disc slightly to secure it in place.

8. Install drive band, ears first, into the notches in the back of the retainer.

The leg of the drive band without ears should be facing away from the

retainer.

9. Turn the bellows inside-out and place it with the retainer/drive band/disc

assembly.

10. Turn the bellows right-side-out, folding the bellows into the lip of the drive

band and completely around the disc. Gently pull on the bellows to

ensure it is properly seated. The disc should not be visible once this step

is completed.

11. Install the primary ring, lapped face up, into the retainer assembly so the

un-lapped face rests against the front flange of the bellows.

12. Lightly lubricate the ID of the bellows. Lightly lubricate the OD of the

entire sleeve for best results.

13. With the sleeve standing on its base, first install the spring, then the

spring adapter. The flat side of the spring adapter should rest on top of

the spring. The adapter should not enclose the spring.

14. Carefully slide the seal head assembly onto the sleeve, ensuring the tail

of the bellows remains flat. Should the bellows roll under, remove the seal

head from the sleeve and restart this step, gently turning the seal head.

Once the seal head assembly is correctly positioned, gently slide it back

and forth once to ensure its mobility.

15. Clean faces of primary and mating rings with denatured alcohol and a

lint-free cloth.

16. With the entire assembly still standing on the sleeve base, carefully lower

the gland plate assembly over the sleeve assembly until the seal faces

touch. Carefully rotate the faces against each other one or two turns.

17. Align set screws in collar with through holes in end of sleeve.

18. Install snap ring over the end of sleeve. This sets the axial spacing of

the cartridge. Do no overcompress gland pla e or his may damage

he seal.

19. Tighten set screws until they start to enter the sleeve ID.

20. Uniformly tighten cap screws on spacers.

21. Install gasket and sleeve O-Ring.

22. Pressure test according to ohn Crane standard QA-5-0568.

Type 5611 and 5611Q Elastomer Bellows Cartridge Seal Assembly (cont.)

I-5611/5611Q - 3 -

*Oversize bore seals only

*Oversize bore seals only