TYPE 670/675/676/680/ECS™

SEALOL®METAL BELLOWS EMISSION CONTAINMENT SEAL

Installation, Operation & Maintenance Instructions

3

3. Determine squareness of seal chamber face to shaft

(0.001 mm per mm/ 0.001" per inch of shaft diameter FIM max.),

and shaft concentricity to the seal chamber.

Typical Type MLS-1 Seal Arrangement

4

5

1

10

26 7 8 9 11 312

General Instructions

1. Study the engineering layout drawing to confirm that the seal gasket

and gland will mate successfully with the stuffing box. There are differ-

ent seal configurations depending on the design of the stuffing box.

Preparing the Equipment

1. Check the stuffing box dimensions and finishes.

2. Measure axial end play (±2.54mm/0.100" max.).

3. Measure shaft runout (±0.127mm/0.005" max.).

4. Measure squareness of the stuffing box to the shaft

(±0.051mm/0.002" max.).

NOTE: If measured dimensions

exceed those values

given, correct the

equipment to meet

specifications prior to

seal installation.

63

SHAFT OR SLEEVE

0.040 LG. X 20˚ CHAM.

BORE

0D +0.000"

-0.002"

63

MOVE SHAFT IN AXIAL DIRECTION

BY HAND. NOTE MEASUREMENT

ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SHAFT

TURN SHAFT BY HAND AND NOTE

MEASUREMENT ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SHAFT

TURN SHAFT BY HAND AND NOTE

MEASUREMENT ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SEAL CHAMBER

FACE

The MLS-1 seal is shipped fully assembled. When ordering a repair kit,

assemble the MLS-1 as follows, referring to the applicable engineering

layout drawing. This assembly is based on installing the repair kit into an

existing seal assembly.

NOTE: These instructions apply to the MLS-1, which is the standard MLS,

and should only be used when installing the components of the

repair kit. Other MLS seal types require different assembly

procedures. Contact John Crane Engineering.

Elastomeric o-rings can be damaged or destroyed if care is not

taken. Prior to assembly of o-rings into their respective grooves,

make sure groove is clean and free of foreign materials. Lubricate

both groove and o-ring prior to installation.

Removing Old Parts

1. Remove sleeve from gland. Save for assembly.

2. Place the gland on table with gasket side facing down.

3. Remove the retaining ring by applying a small flathead screwdriver

to the split in the ring.

4. Remove all interior components, saving the compression ring for

assembly. Remove O-ring from sleeve.

Do not reuse O-rings.

Assembling Repair Kit

1. With gasket side facing down, install a gland O-ring into the gland.

2. Insert the first sealing element into the gland with the end of the arc

facing down.

3. Install a gland O-ring onto the o-ring spacer in the OD groove.

Insert the O-ring spacer into the gland with O-ring side facing up.

4. Insert the second sealing element into the gland with the end of

the arc facing down. Insert the spacer into the gland with small

ID facing down.

5. Insert the third sealing element into the gland with the end of the arc

facing down. Install a gland O-ring onto the compression ring in the

OD groove.

6. Insert the compression ring into the gland with O-ring side

facing down.

(continued on page 3)

Type MLS-1 Seal Assembly (Repair Kit)

Part Name

1 Gland 7 Chemlon Seal

2 Sleeve 8 O-ring Spacer

3 Set Screws 9 Flush Spacer

4 Gasket 10 Retaining Ring

5 Gland O-ring 11 Setting Spacer

6 Sleeve O-ring 12 Compression Ring

!

TYPE MLS-1

CHEMLON CARTRIDGE SEAL

Installation, Operation & Maintenance Instructions

PAGE 2

4. Measure shaft runout (0.001mm/0.001" per inch per mm of shaft

diameter FIM max.).

Typical Type MLS-1 Seal Arrangement

4

5

1

10

26 7 8 9 11 312

General Instructions

1. Study the engineering layout drawing to confirm that the seal gasket

and gland will mate successfully with the stuffing box. There are differ-

ent seal configurations depending on the design of the stuffing box.

Preparing the Equipment

1. Check the stuffing box dimensions and finishes.

2. Measure axial end play (±2.54mm/0.100" max.).

3. Measure shaft runout (±0.127mm/0.005" max.).

4. Measure squareness of the stuffing box to the shaft

(±0.051mm/0.002" max.).

NOTE: If measured dimensions

exceed those values

given, correct the

equipment to meet

specifications prior to

seal installation.

63

SHAFT OR SLEEVE

0.040 LG. X 20˚ CHAM.

BORE

0D +0.000"

-0.002"

63

MOVE SHAFT IN AXIAL DIRECTION

BY HAND. NOTE MEASUREMENT

ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SHAFT

TURN SHAFT BY HAND AND NOTE

MEASUREMENT ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SHAFT

TURN SHAFT BY HAND AND NOTE

MEASUREMENT ON DIAL INDICATOR

MOUNT

DIAL INDICATOR

ON SEAL CHAMBER

FACE

The MLS-1 seal is shipped fully assembled. When ordering a repair kit,

assemble the MLS-1 as follows, referring to the applicable engineering

layout drawing. This assembly is based on installing the repair kit into an

existing seal assembly.

NOTE: These instructions apply to the MLS-1, which is the standard MLS,

and should only be used when installing the components of the

repair kit. Other MLS seal types require different assembly

procedures. Contact John Crane Engineering.

Elastomeric o-rings can be damaged or destroyed if care is not

taken. Prior to assembly of o-rings into their respective grooves,

make sure groove is clean and free of foreign materials. Lubricate

both groove and o-ring prior to installation.

Removing Old Parts

1. Remove sleeve from gland. Save for assembly.

2. Place the gland on table with gasket side facing down.

3. Remove the retaining ring by applying a small flathead screwdriver

to the split in the ring.

4. Remove all interior components, saving the compression ring for

assembly. Remove O-ring from sleeve.

Do not reuse O-rings.

Assembling Repair Kit

1. With gasket side facing down, install a gland O-ring into the gland.

2. Insert the first sealing element into the gland with the end of the arc

facing down.

3. Install a gland O-ring onto the o-ring spacer in the OD groove.

Insert the O-ring spacer into the gland with O-ring side facing up.

4. Insert the second sealing element into the gland with the end of

the arc facing down. Insert the spacer into the gland with small

ID facing down.

5. Insert the third sealing element into the gland with the end of the arc

facing down. Install a gland O-ring onto the compression ring in the

OD groove.

6. Insert the compression ring into the gland with O-ring side

facing down.

(continued on page 3)

Type MLS-1 Seal Assembly (Repair Kit)

Part Name

1 Gland 7 Chemlon Seal

2 Sleeve 8 O-ring Spacer

3 Set Screws 9 Flush Spacer

4 Gasket 10 Retaining Ring

5 Gland O-ring 11 Setting Spacer

6 Sleeve O-ring 12 Compression Ring

!

TYPE MLS-1

CHEMLON CARTRIDGE SEAL

Installation, Operation & Maintenance Instructions

PAGE 2

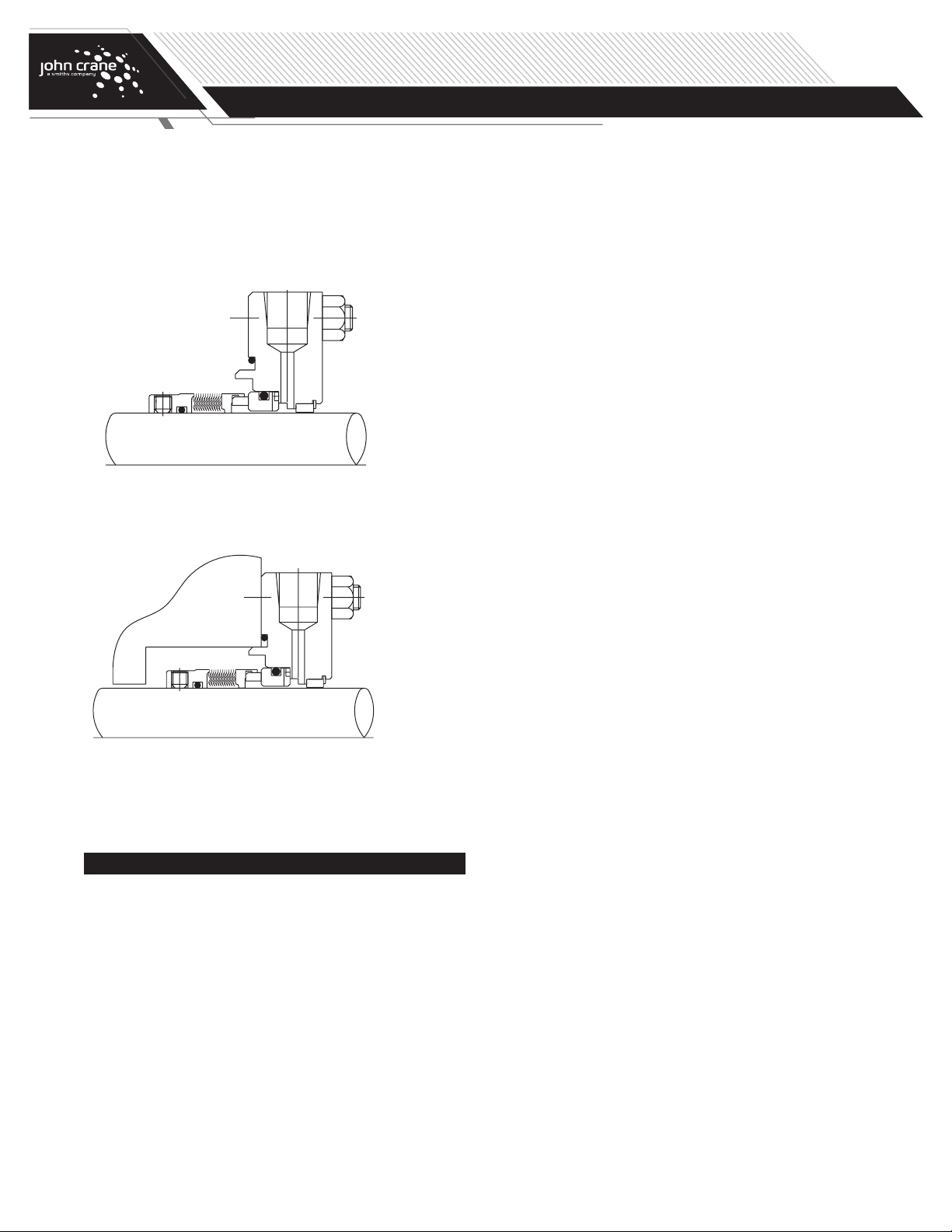

Component Seals

Setting the seal

1. With the seal chamber and shaft/sleeve in their correct operating

positions, use a straight edge to scribe the position of the seal

chamber face onto the shaft/sleeve at A. Use machinist’s blue to make

the scribe easier to see.

2. Again remove the pump housing. From the installation drawing,

determine the distance from the seal chamber face to the seal set

length, and scribe line B onto the shaft sleeve at this distance.

3. Without disturbing the scribe line B, wipe the shaft/sleeve clean and

apply a lubricant which is compatible with the sealed fluid and the

gasketing materials.

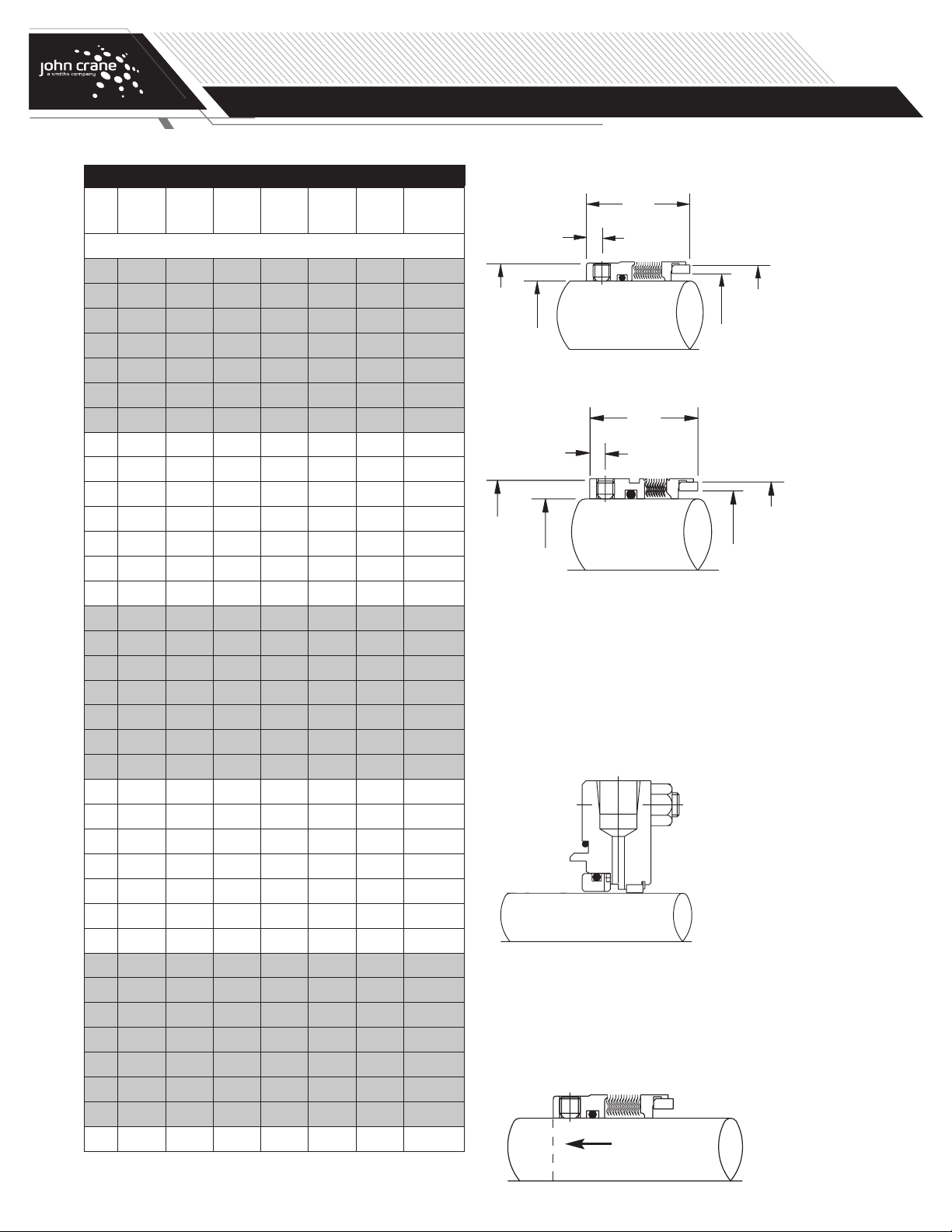

Type 670/675/676/680 Dimensional Data (mm)

Sealol

Dash

No.

Shaft

Size

A B C D E F

Set Screw

Size/Qty

670/680 670 680

-024 24.00 38.10 29.79 34.93 4.50 30.00 M5 x 3 M5 x 3

-025 25.00 39.00 30.50 35.68 4.50 30.00 M5 x 3 M5 x 3

-028 28.00 42.00 33.50 38.68 5.50 32.50 M5 x 3 M5 x 3

-030 30.00 44.00 35.50 40.68 5.10 32.50 M5 x 3 M5 x 3

-032 32.00 46.02 38.51 43.66 5.10 32.50 M5 x 3 M5 x 3

-033 33.00 47.00 38.20 44.63 4.50 32.50 M5 x 3 M5 x 3

-035 35.00 49.20 41.68 46.86 4.50 32.50 M5 x 3 M5 x 3

-038 38.00 52.37 43.59 50.04 5.20 34.00 M6 x 3 M6 x 3

-040 40.00 55.55 46.76 53.21 5.20 34.00 M6 x 3 M6 x 3

-043 43.00 58.72 49.94 56.39 5.20 34.00 M6 x 3 M6 x 3

-045 45.00 58.72 49.94 56.39 5.20 34.00 M6 x 3 M6 x 3

-048 48.00 61.90 53.09 59.56 5.00 34.00 M6 x 3 M6 x 3

-050 50.00 65.07 56.29 62.76 5.20 34.50 M6 x 3 M6 x 3

-053 53.00 68.25 59.44 65.91 5.20 34.50 M6 x 3 M6 x 3

-055 55.00 71.00 62.00 68.45 4.60 34.50 M6 x 3 M6 x 3

-058 58.00 74.60 65.79 72.29 6.60 39.50 M6 x 3 M8 x 3

-060 60.00 74.60 65.79 72.29 6.60 39.50 M6 x 3 M8 x 3

-063 63.00 80.95 70.87 78.64 6.60 39.50 M6 x 3 M8 x 3

-065 65.00 84.12 74.04 81.81 6.00 39.50 M6 x 3 M8 x 3

-068* 68.00 87.30 77.22 85.01 5.10 37.50 — M8 x 3

-070 70.00 87.30 77.22 85.01 8.20 45.00 M6 x 3 M8 x 3

-075 75.00 95.25 84.38 92.13 7.80 45.00 M6 x 3 M8 x 3

-080 80.00 98.43 87.30 95.81 6.70 44.50 M8 x 4 M8 x 3

-085 85.00 104.78 93.65 102.16 6.70 44.50 M8 x 4 M8 x 3

-090 90.00 107.95 96.82 105.33 9.00 49.50 M8 x 4 M8 x 3

-095 95.00 114.30 103.17 111.68 9.00 49.50 M8 x 4 M8 x 3

-100 100.00 120.65 109.52 118.03 9.00 49.50 M8 x 4 M8 x 3

-102 102.00 120.65 109.52 118.03 9.00 49.50 M8 x 4 —

-105 105.00 131.75 115.49 124.76 7.10 48.50 M8 x 4 —

-110 110.00 138.13 126.44 131.14 7.10 48.50 M8 x 4 —

-115 115.00 144.48 128.22 137.49 7.10 48.50 M8 x 4 —

-120 120.00 144.48 128.22 137.49 7.10 48.50 M8 x 4 —

-125 125.00 150.83 134.59 143.87 7.10 48.50 M8 x 4 —

-130 130.00 157.81 140.56 150.85 7.10 48.50 M8 x 4 —

-140 140.00 170.54 153.31 163.60 7.10 48.50 M8 x 4 —

-150 150.00 176.89 159.66 169.98 7.10 48.50 M8 x 4 —

NOTE: If measured

dimensions exceed those

values given, correct

the equipment to meet

specifications prior to

seal installation.

* 670 is not available in 68mm size.