ROPAC COMPONENT SEALS

Installation, Operation & Maintenance Instructions

2

TYPE R33/34/50

5. Transportation and Storage

Transport and store the seal in its original packaging. To ensure

seals remain in good condition they should be stored in the following

environment:

1. Dry and dust-free

2. Ventilated at room temperature

3. Protected from direct effects of heat and ultraviolet light

4. All the elastomers used in the mechanical seal have a minimum shelf

life of 5 years except for butyl rubber which has a minimum shelf life

of 2 years. We recommend that the elastomers be replaced at these

intervals. It is also recommended that the elastomer replacement be

carried out by John Crane personnel.

If used seal parts are to be shipped they must be

cleaned and decontaminated before shipping. It is

the responsibility of the machine user to ensure

that any parts being shipped have appropriate

safe-handling instructions externally attached

to the package. Without this information there

will be a refusal to handle the goods. If required

a decontamination/transportation certificate is

available from John Crane. Refer to document

EDS1001.

For additional information on transportation and storage, contact your

local John Crane facility and request a copy of document I-Storage.

If any machine with an installed component seal has been stored with

preservatives, before putting it back into operation the seal must be

removed, cleaned and dried. Particular attention must be applied to the

cleanliness of the faces and condition of the elastomers. For an installed

cartridge seal we recommend returning the complete cartridge to John

Crane for cleaning.

ATTENTION Ensure preservatives and cleaning agents do not affect

the elastomers.

ATTENTION Once the seal is fitted on the machine and the position

is set using setting devices do not re-engage them for

transportation and storage.

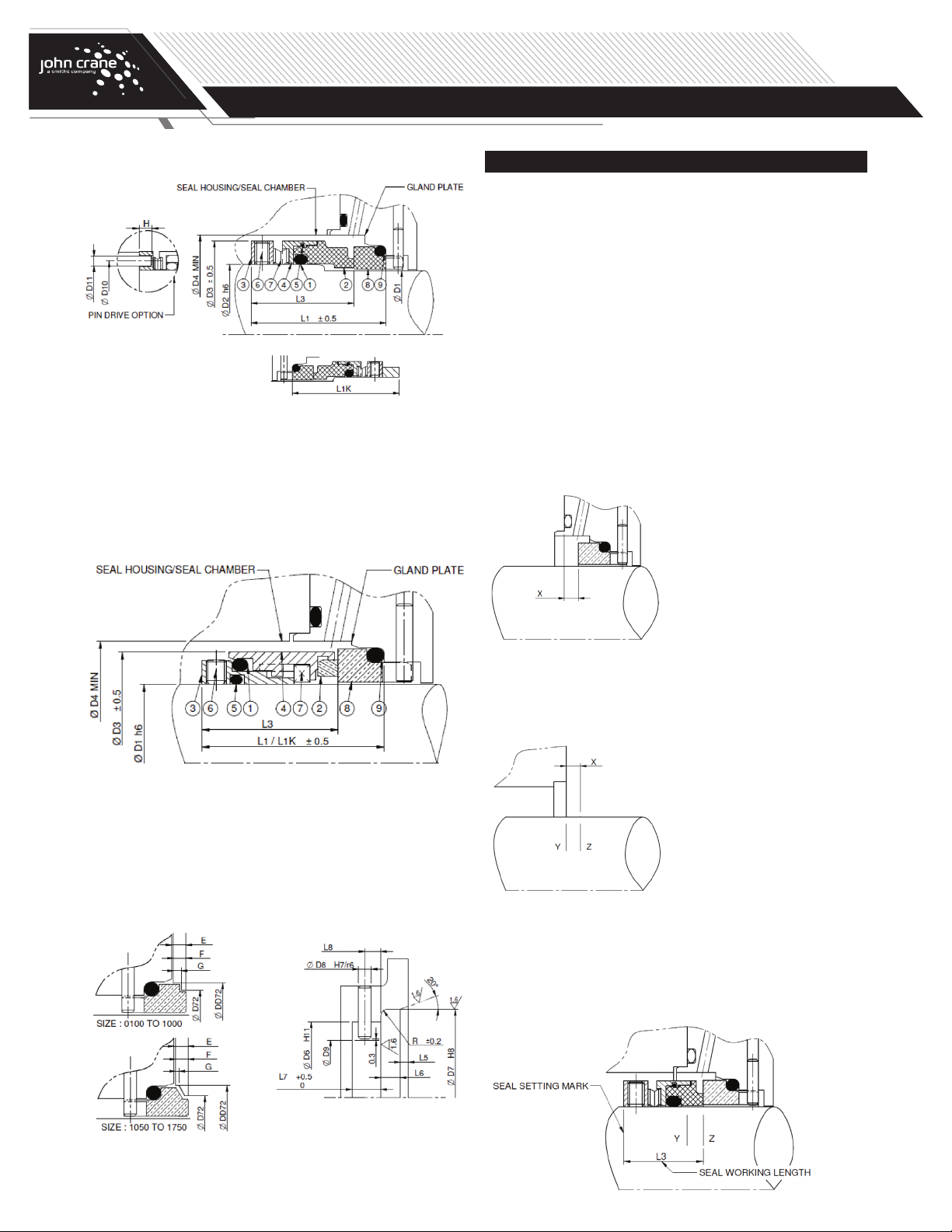

6. Seal Installation

Refer to the appropriate seal family installation instructions. Do not

excessively compress the seal before or during installation.

7. Before Starting the Equipment

1. Check the machine at the coupling for proper alignment of the driver

or motor.

2. Ensure that the gland plate nuts/bolts are securely tightened

according to the pump manual instructions, and all screws are

securely fastened.

3. Complete the assembly of the pump and turn the shaft (by hand if

possible) to ensure free rotation.

4. Consult all available equipment operating instructions to check for

correctness of all piping and connections, particularly regarding seal

recirculation/flush, heating or cooling requirements, and services

external to the seal.

ATTENTION This mechanical seal is designed to operate in a liquid,

so the heat energy it creates is adequately removed.

The following check should be carried out not only after

seal installation, but also after any period of equipment

inactivity.

5. Check that the seal chamber fluid lines are open and free of any

obstruction, and ensure that the seal chamber is properly vented and

filled with liquid — refer to the pump instruction manual.

ATTENTION Except for dry running or gas lubricated seals which are

designed to operate without liquid, wet seals that are

operated without adequate liquid lubrication will often

give rise to a squealing noise from the seal area and

result in overheating and scoring or other damage to

the sealing surfaces, causing excessive emissions and a

reduced seal life.

Before start-up, ensure that all personnel and

assembly equipment have been moved to a safe

distance so there is no contact with rotating parts

on the pump, seal, coupling or motor.

ATTENTION Seal installation should be handled only by

qualified personnel. If questions arise, contact

the local John Crane representative. Improper use

and/or installation of this product could result

in injury to the person and/or harmful emissions

to the environment, and may affect any warranty

on the product. Please contact the company for

information as to exclusive product warranty and

limitations of liability.

8. Maintenance

During operation, periodic visual external inspection of the seal should

be carried out. A measure of seal condition is the level of emission of the

process or barrier fluid and as no maintenance is possible while installed,

the seal should be replaced when emissions become unacceptable. It is

recommended that a spare seal be held in inventory to allow immediate

replacement of a removed seal.

ATTENTION Machine adjustments that involve axial movement of the

shaft may cause damage to the seal while installed.

Before attempting impeller clearance adjustment with a cartridge seal,

refit the spacers then loosen all the drive collar socket set screws. With

the shaft in its new working position, tighten with new socket set screws

and remove the spacers. Keep the spacers for future use.

For a component seal (non-cartridge), remove the seal, adjust the

impeller clearance then re-fit the seal at its correct working length.