5. If the pumped fluid is hazardous or toxic, appropriate precautions

must be taken to ensure that any seal leakage is adequately

contained. Further information on sealing hazardous or toxic fluids

should be obtained from John Crane prior to seal installation.

6. Fluorocarbon components should never be burned or incinerated

as the fumes and residues are highly toxic. If fluorocarbons are

accidentally heated above 400˚C/750˚F, they can decompose.

Protective gloves should be worn as hydrofluoric acid may be present.

7. PTFE components should never be burned or incinerated as the

fumes are highly toxic.

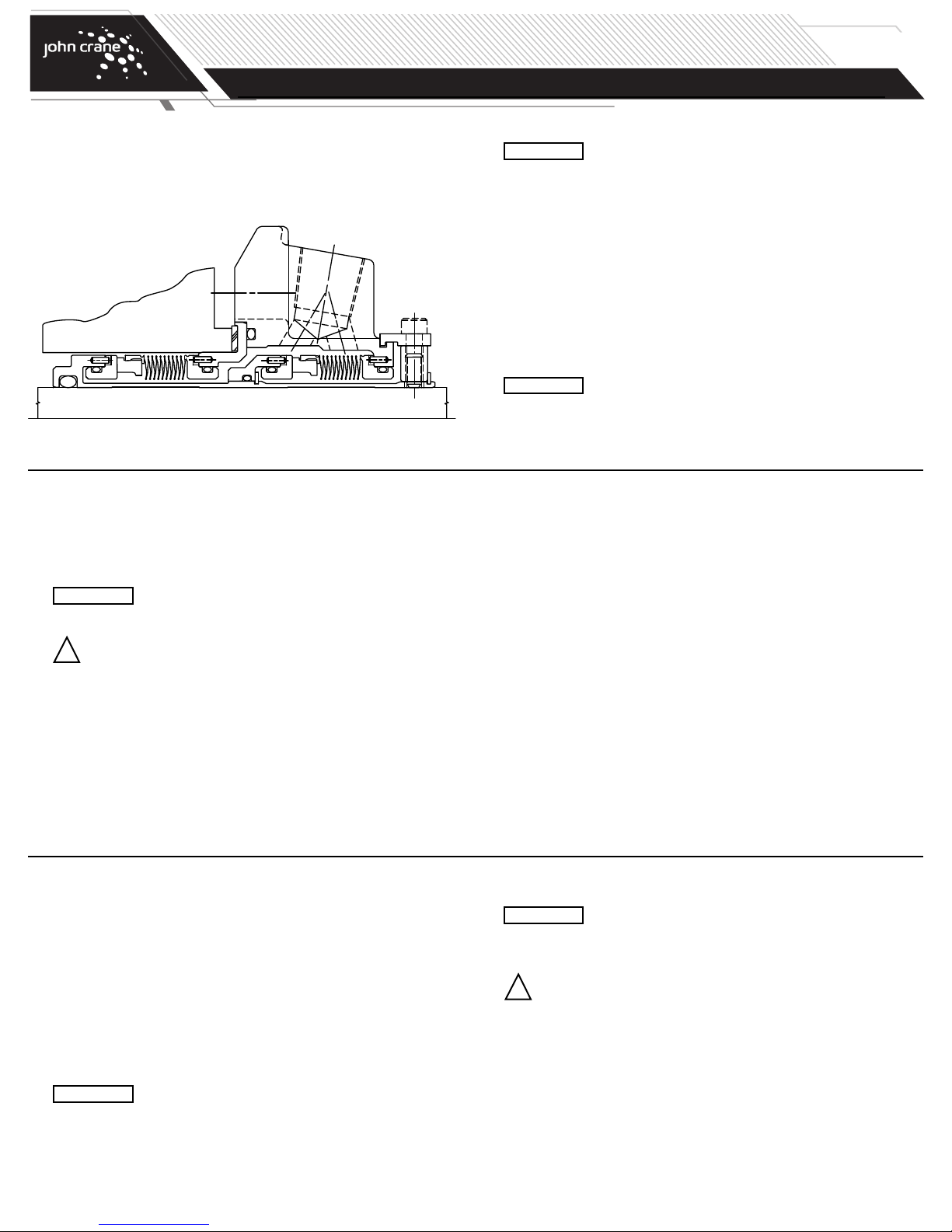

These instructions are for the installation and operation of

a seal as used in rotating equipment and will help to avoid

danger and increase reliability. The information required

may change with other types of equipment or installation

arrangements. These instructions must be read in

conjunction with the instruction manuals for both the

pump and any ancillary equipment.

If the seal is to be used for an application other than that originally

intended or outside the recommended performance limits, John Crane

must be contacted before its installation and use.

Any warranty may be affected by improper handling, installation, or use

of this seal. Contact John Crane for information as to exclusive product

warranty and limitations of liability.

If questions or problems arise, contact your local John Crane representative

or the original equipment manufacturer, as appropriate.

John Crane mechanical seals are precision products and

must be handled appropriately. Take particular care to

avoid damage to lapped sealing faces and to flexible

sealing rings. Do not excessively compress the seal

before or during installation.

Safety Instructions

1. The following designations are used in the installation instructions to

highlight instructions of particular importance.

NOTE: Refers to special information on how to install or

operate the seal most efficiently.

Refers to special information or instructions directed

towards the prevention of damage to the seal or its

surroundings.

Refers to mandatory instructions designed to

prevent personal injury or extensive damage to the

seal or its surroundings.

2. Installation, removal and maintenance of the seal must be carried out

only by qualified personnel who have read and understood these

installation instructions.

3. The seal is designed exclusively for sealing rotating shafts. The

manufacturer cannot be held liable for use of the seal for purposes

other than this.

4. The seal must only be used in technically perfect condition and

must be operated within the recommended performance limits in

accordance with its designated use set out in these installation

instructions.

Dry-running - often indicated by a squealing noise from

the seal area - will cause overheating and scoring or other

damage to the sealing surfaces, resulting in excessive

leakage or a much shortened seal life.

Before start-up, ensure that all personnel and

assembly equipment have been moved to a safe

distance so there is no contact with rotatin parts

on the pump, seal, couplin , or motor.

WARNING: Seal installation should be handled only by qualified

personnel. If questions arise, contact the local

John Crane representative. Improper use and/or

installation of this product could result in injury to

the person and/or harmful emissions to

the environment, and may affect any warranty

on the product. Please contact John Crane for

information as to exclusive product warranty

and limitations of liability.

Before Startin the Equipment

1. Check the pump at the coupling for proper alignment of the driver

or motor.

2. Ensure that the gland plate nuts/bolts are securely tightened

according to the pump manual instructions, and that all screws are

securely fastened.

3. Complete the assembly of the pump, and turn the shaft (by hand if

possible) to ensure free rotation.

4. Consult all available equipment operating instructions to check for

correctness of all piping and connections, particularly regarding seal

recirculation/flush, heating or cooling requirements, and services

external to the seal.

This mechanical seal is designed to operate in a liquid

so the heat energy it creates is adequately removed.

Therefore, the following check should be carried out

not only after seal installation, but also after any

period of equipment inactivity.

5. Check that the seal chamber fluid lines are open and free of any

obstruction, and ensure that the seal chamber is properly vented

and filled with liquid - refer to the pump instruction manual.

ATTENTION

ATTENTION

ATTENTION

!

ATTENTION

ATTENTION

!

Foreword

These instructions are provided to familiarize the user with the seal

and its designated use. The instructions must be read and applied

whenever work is done on the seal, and must be kept available for

future reference.

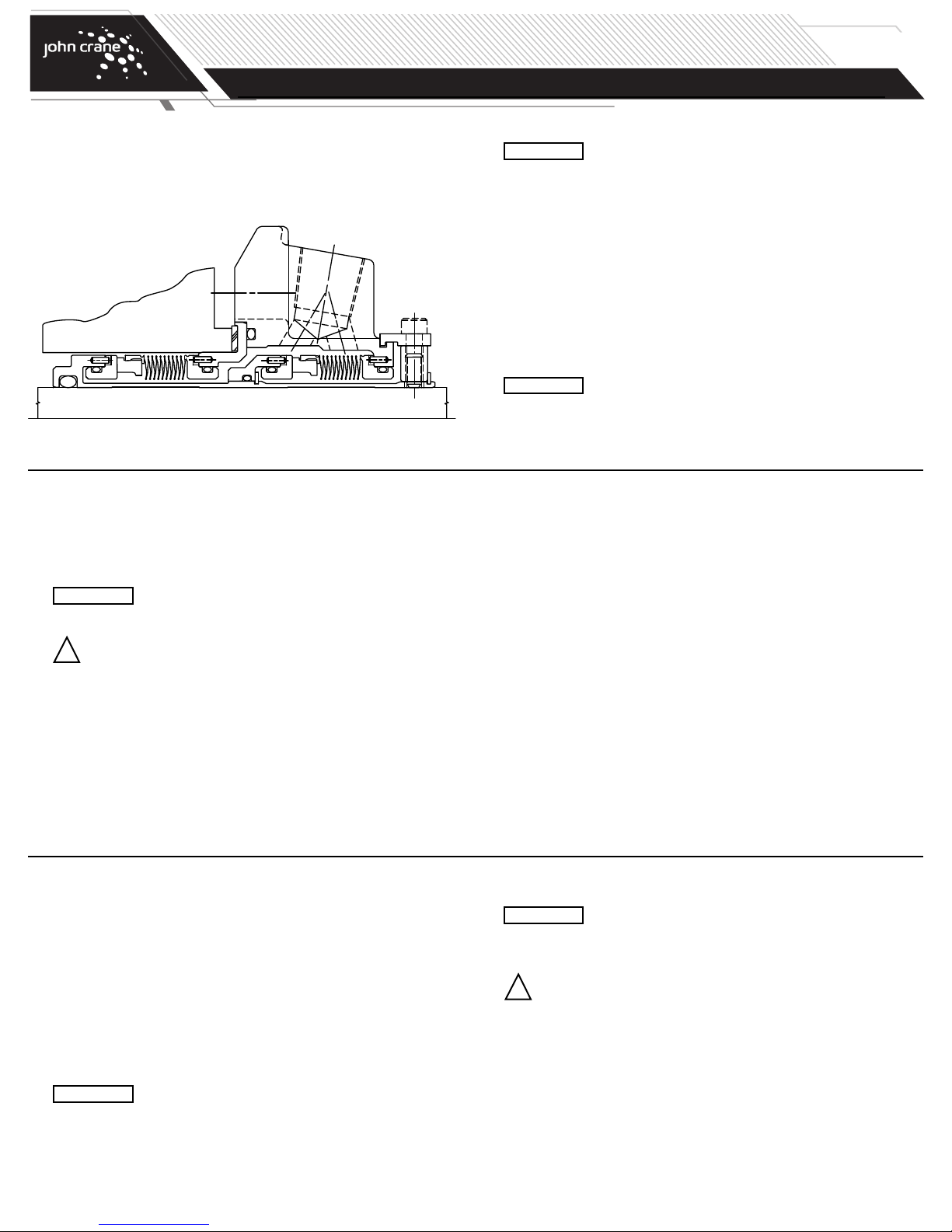

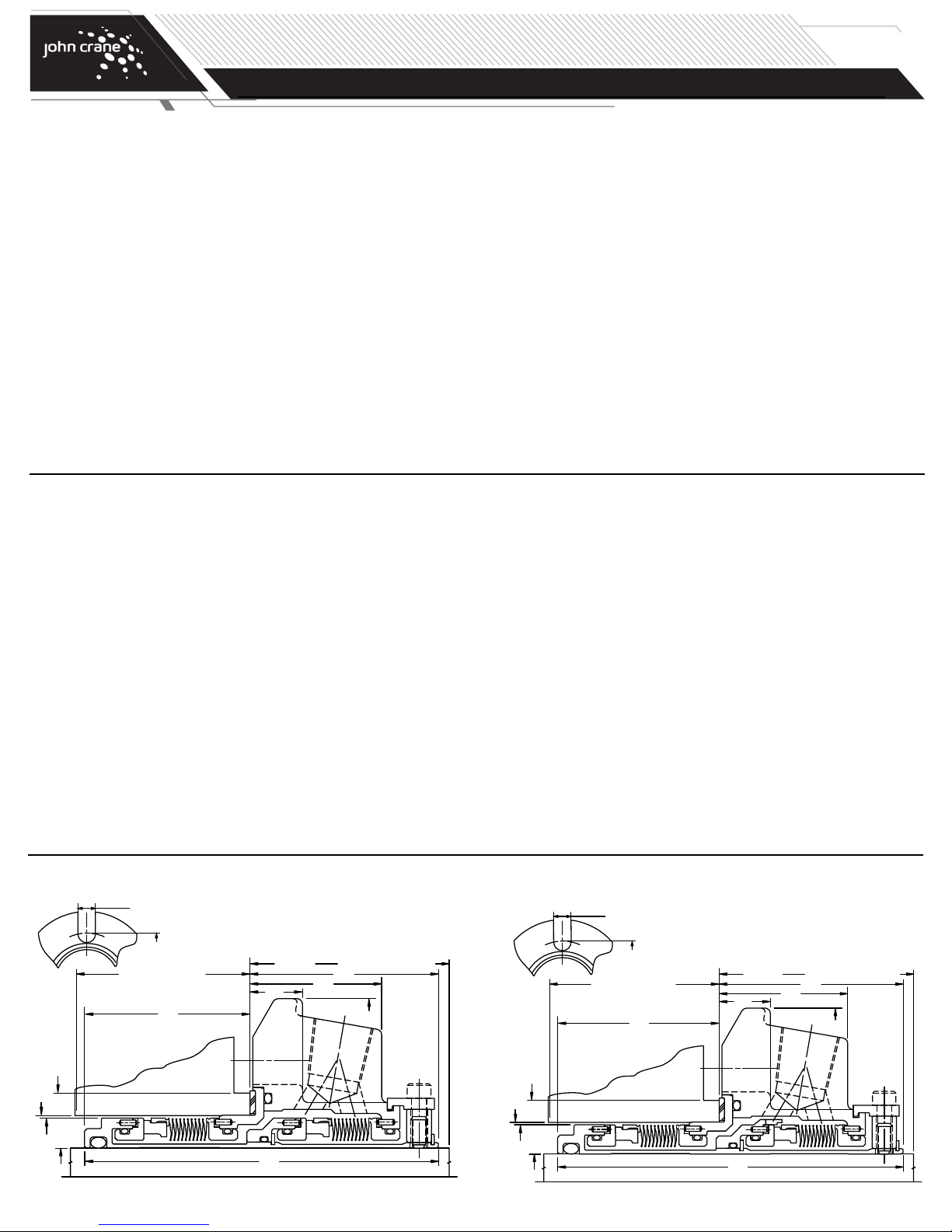

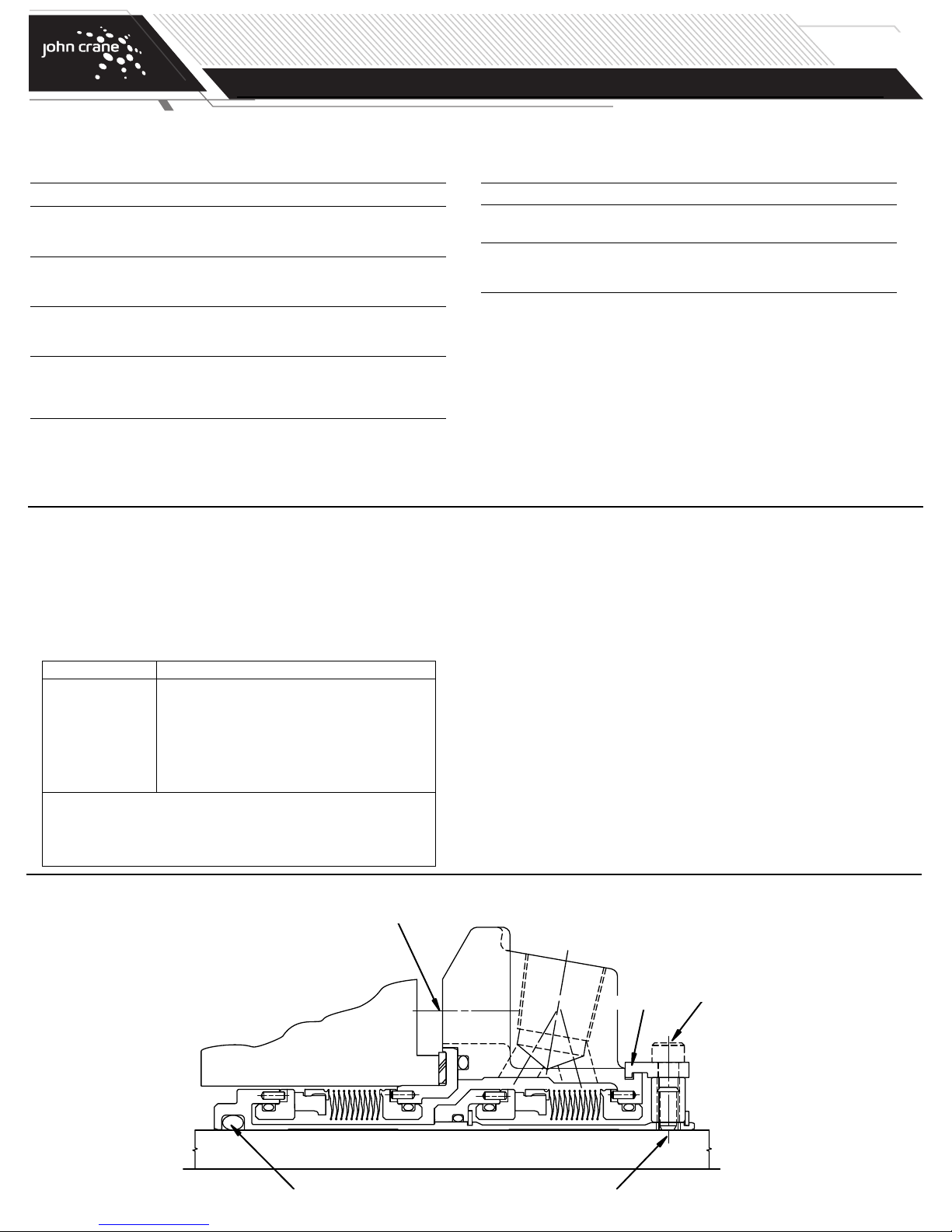

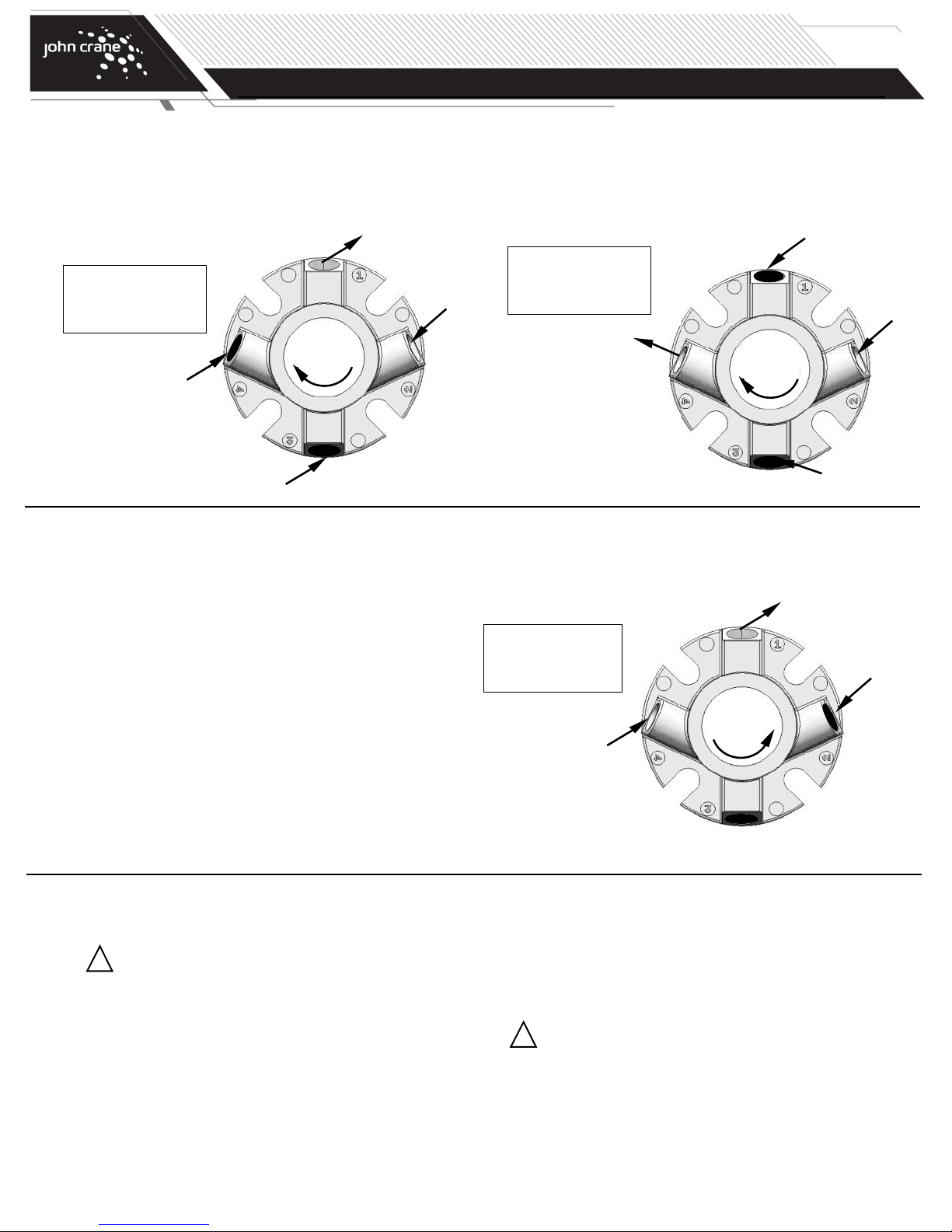

TYPE 5625/5625P

DUAL METAL BELLOWS CARTRIDGE SEAL

Installation, Operation & Maintenance Instructions

PAGE 1