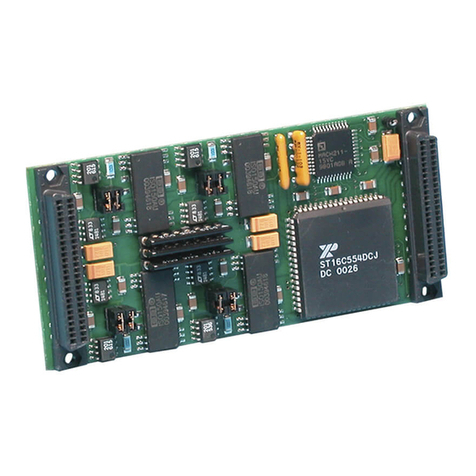

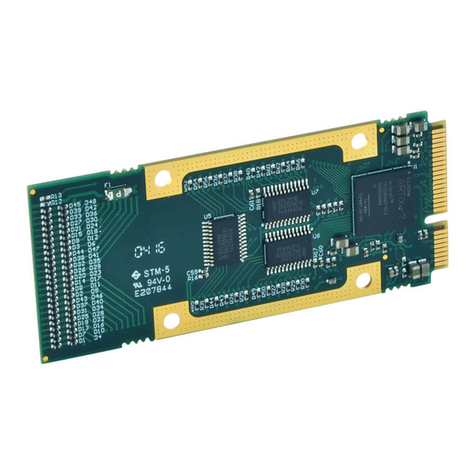

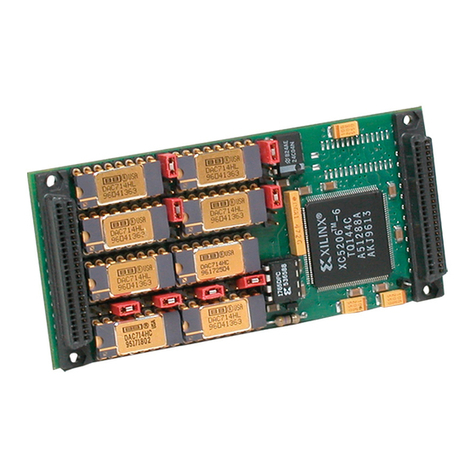

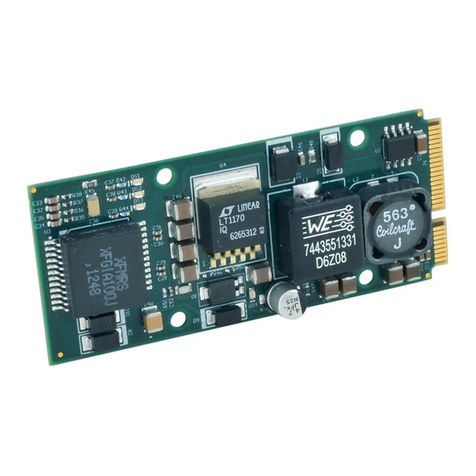

SERIES IOS-445 I/O SERVER MODULE 32 CHANNEL ISOLATED SSR OUTPUT MODULE

____________________________________________________ _____________________________________

-

-

Acromag,

Inc.

Tel:248-

295-0310 Fax:248-624-9234 Email:[email protected] http://www.acromag.com

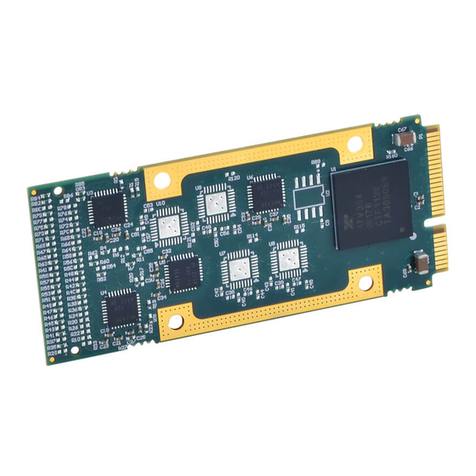

4.0 THEORY OF OPERATION

This section contains information regarding the basic

functionality of the circuitry used on the IOS-445. Refer to the IOS-

445 BLOCK DIAGRAM located at the end of this manual as you

review this material.

OUTPUT PORTS

The field I/O interface to the carrier board is provided through

connector P2 (refer to Table 2.1). Individual Solid State Relays

(SSR‟s) for each channel isolate the field from the control logic for

the IOS-445. Channels are isolated from each other in groups of

eight. There are eight channels to a group or port. Because the

output lines of a single port share a common connection, individual

outputs are not isolated from each other within the same port.

However, separate port commons are provided to facilitate port-to-

port isolation.

32 Single Pole Single Throw - Normally Open (SPST-NO,

“1 Form A”) SSR outputs are controlled by this module. Each

group of eight channels can be connected directly to positive or

negative supplies for high (hot) side switching. Alternatively, each

group of eight channels can be connected to common for low side

switching. Socketed pull-up resistors are provided for low side

switching applications. These resistors should be removed if high

side switching is needed. In low side switching applications the

resistor values can be changed (e.g. lower values will provide a

faster pull-up while a higher values will keep power dissipation from

becoming a problem at higher voltages) - see Specifications in

Chapter 6 for details.

The SSR‟s are controlled by output registers within the FPGA.

Writing a „1‟ to the output register will turn the switch ON (closed-

circuit) while writing a „0‟ will turn it OFF (open-circuit). Readback

of the output state is accomplished by reading the output registers.

However, for complete confidence in output control, loopback

should be performed. This may be accomplished using the IOS-

440 isolated digital input module (refer to IOS-440/IOS-445

LOOPBACK CONNECTIONS).

The SSR‟s employed are rated for a much higher voltage than

specified. However, the field connector and printed circuit board

foil spacings limit applied voltages to +/-60VDC or AC peak. Each

port (group of eight channels) has a single common. Since the

connectors and cables are rated to 1A maximum per pin, then each

port is limited to that total current. Thus, the sum of currents

conducted by the 8 channels must stay below that total (see

specifications in Chapter 6 for details). The low on resistance of

the SSR‟s helps reduce their power dissipation when they conduct

high currents; however, given the large number of channels on the

board adequate air circulation must be maintained. The SSR‟s

used in the IOS-445 are very rugged and contain built-in current

limiting for their protection. They provide clean, bounce free

switching and can replace electromechanical relays in many

applications. SSR switching speeds are comparable to

electromechanical relays (1mS. typical) but are slow compared to

high speed optocouplers.

Output operation is “Fail-safe”. That is, the outputs are always

OFF upon power-up reset, and are automatically cleared following

a software (control register) or system software reset. This is done

for safety reasons to ensure reliable control of the output state

under all conditions.

5.0 SERVICE AND REPAIR

SERVICE AND REPAIR ASSISTANCE

Surface-Mounted Technology (SMT) boards are generally

difficult to repair. It is highly recommended that a non-functioning

board be returned to Acromag for repair. The board can be

damaged unless special SMT repair and service tools are used.

Further, Acromag has automated test equipment that thoroughly

checks the performance of each board. When a board is first

produced and when any repair is made, it is tested, placed in a

burn-in room at elevated temperature, and retested before

shipment.

Please refer to Acromag's Service Policy Bulletin or contact

Acromag for complete details on how to obtain parts and repair.

PRELIMINARY SERVICE PROCEDURE

Before beginning repair, be sure that all of the procedures in

Section 2, Preparation For Use, have been followed. Also, refer to

the documentation of your carrier board to verify that it is correctly

configured. Verify that there are no blown fuses. Replacement of

the carrier and/or IOS with one that is known to work correctly is a

good technique to isolate a faulty board.

CAUTION: POWER MUST BE TURNED OFF BEFORE

REMOVING OR INSERTING BOARDS

WHERE TO GET HELP

If you continue to have problems, your next step should be to

visit the Acromag worldwide web site at http://www.acromag.com.

Our web site contains the most up-to-date product and software

information.

Go to the “Support” tab to access:

Application Notes

Frequently Asked Questions (FAQ‟s)

Product Knowledge Base

Tutorials

Software Updates/Drivers

An email question can also be submitted from within the

Knowledge Base or directly from the “Contact Us” tab.

Acromag‟s application engineers can also be contacted directly

for technical assistance via telephone or FAX through the numbers

listed below. When needed, complete repair services are also

available.

Phone: 248-295-0310

Fax: 248-624-9234

Email: solutions@acromag.com