Johnson Controls C-9500 User manual

Other Johnson Controls Irrigation System manuals

Johnson Controls

Johnson Controls tyco AQUAMIST ULF AM29 User manual

Johnson Controls

Johnson Controls tyco TY-B Series User manual

Johnson Controls

Johnson Controls tyco ESFR-17 User manual

Johnson Controls

Johnson Controls tyco RFII-MRI Series User manual

Johnson Controls

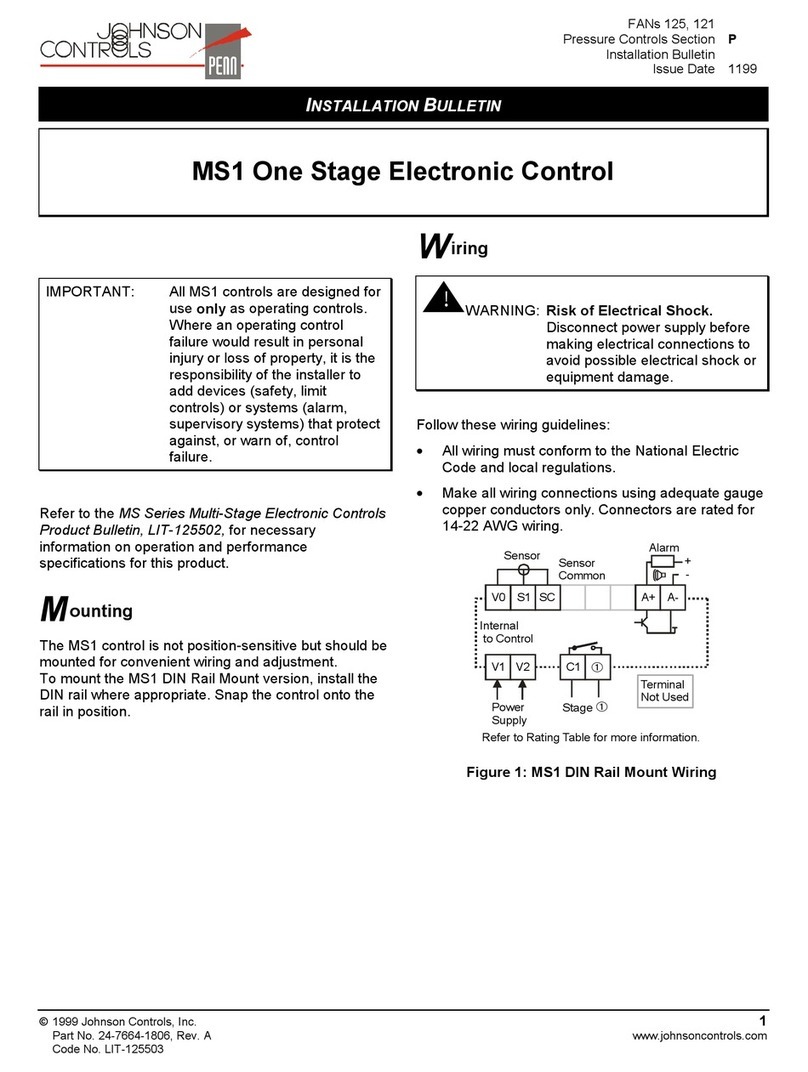

Johnson Controls MS1 Manual

Johnson Controls

Johnson Controls tyco TY-FRB Series User manual

Johnson Controls

Johnson Controls tyco TY-B Series User manual

Johnson Controls

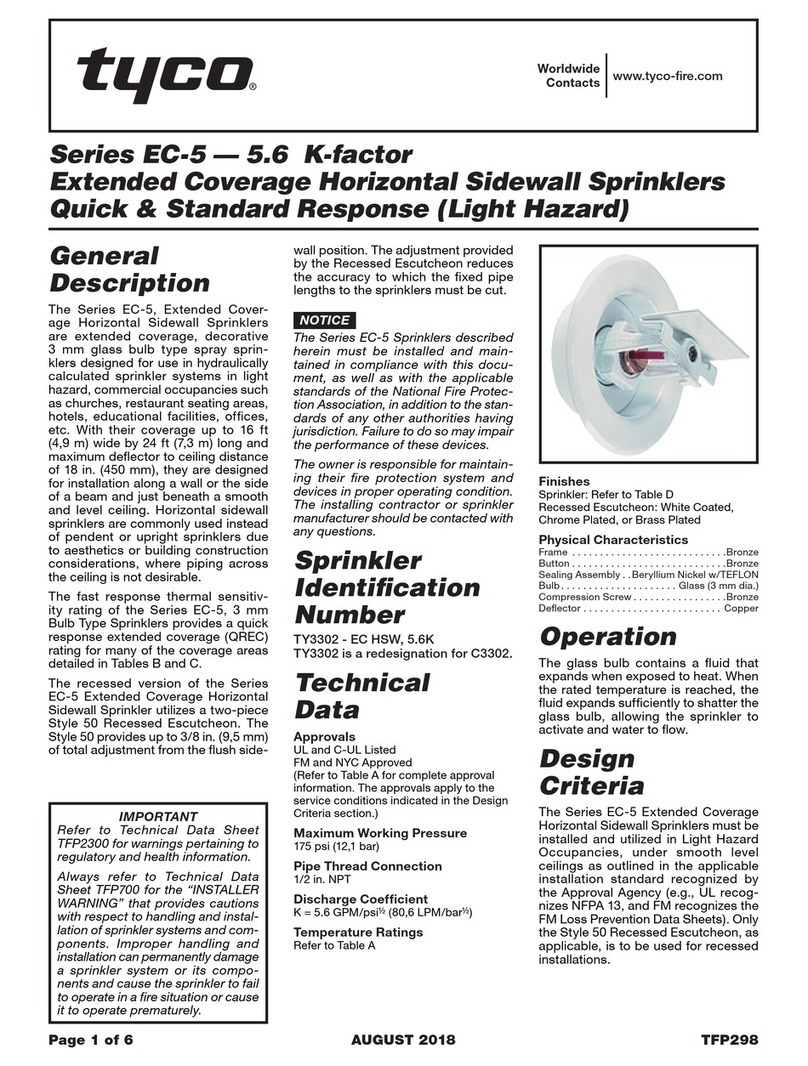

Johnson Controls tyco EC-5 Series User manual

Johnson Controls

Johnson Controls tyco RFII Series User manual

Johnson Controls

Johnson Controls tyco RAPID RESPONSE LFII Series User manual

Johnson Controls

Johnson Controls tyco ESFR-34 User manual

Johnson Controls

Johnson Controls tyco LD User manual

Johnson Controls

Johnson Controls tyco TY1234 User manual

Johnson Controls

Johnson Controls Tyco EC-11 Series User manual

Johnson Controls

Johnson Controls tyco AQUAMIST ULF AM15 User manual

Johnson Controls

Johnson Controls tyco TY-FRB Series User manual

Johnson Controls

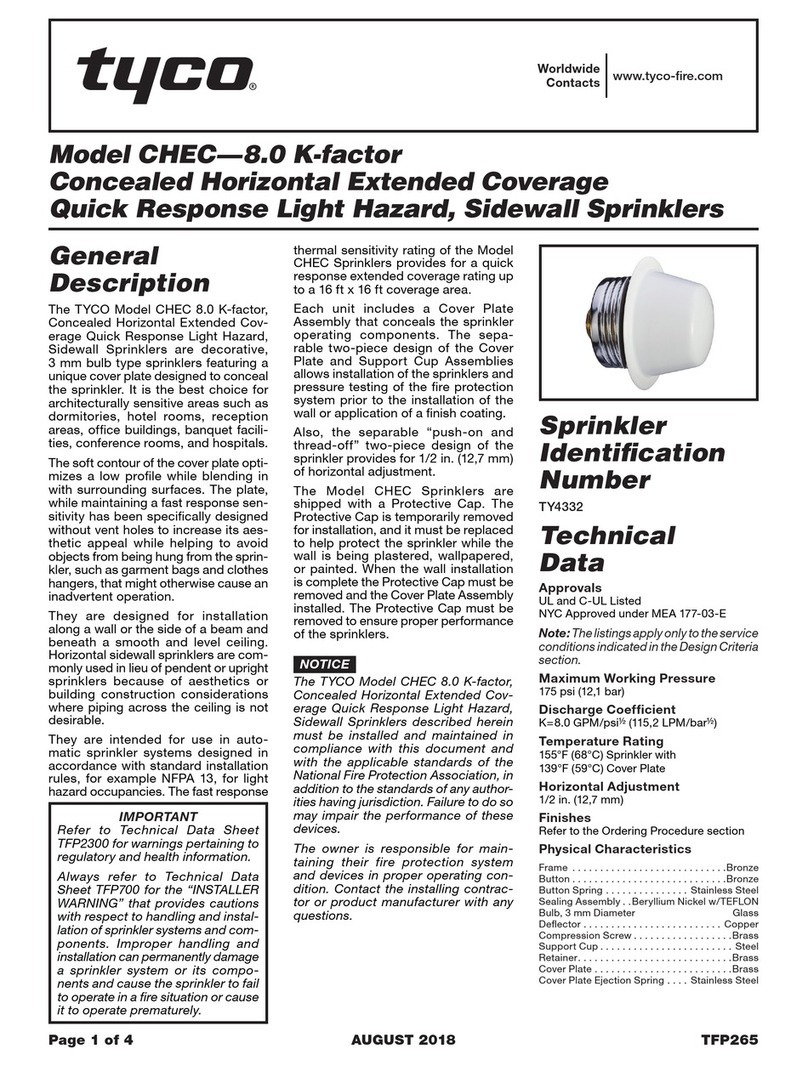

Johnson Controls tyco CHEC User manual

Johnson Controls

Johnson Controls tyco TY-FRB Series User manual

Johnson Controls

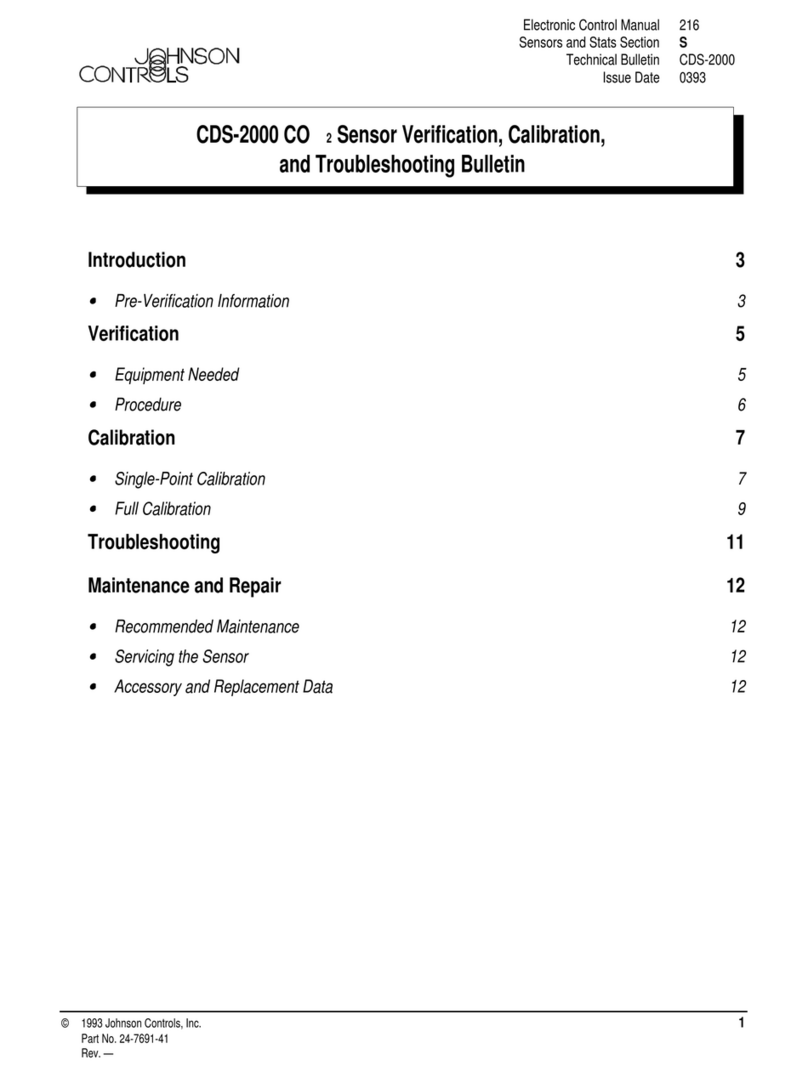

Johnson Controls CDS-2000 User manual

Johnson Controls

Johnson Controls tyco TFP PH2 User manual

Popular Irrigation System manuals by other brands

Tyco Fire Product

Tyco Fire Product Star Galaxy SGQR instruction manual

Tyco Fire Product

Tyco Fire Product CENTRAL A instruction manual

Oral Care Technologies

Oral Care Technologies Hydro Floss Instructions for use

Reliable

Reliable F1-300 quick start guide

Tyco Fire Product

Tyco Fire Product Gem F892 instruction manual

Irrigation-Mart

Irrigation-Mart KIT-GK100-RV-B quick start guide