TFP2242

Page 4 of 4

NATIONAL FIRE PROTECTION ASSOCIATION and NFPA are registered trademarks of National Fire Protection Association;

TEFLON is a registered trademark of DuPont

1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

© 2018 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document revision date and are subject to change without notice.

Step 8. Connect system pipe or fitting.

•

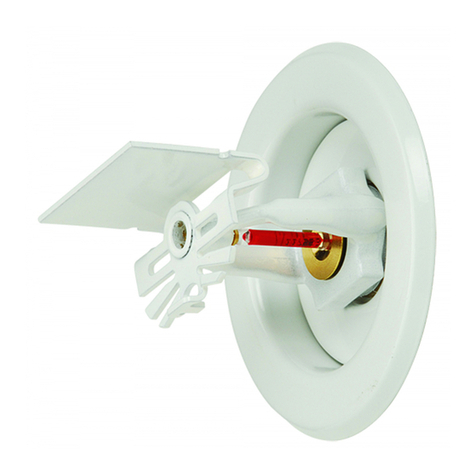

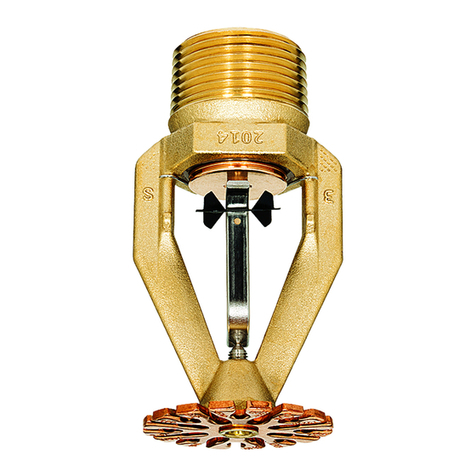

Threaded Fitting Installations

(Figure 1) - With TEFLON paste

sealant applied to IFP Fitting pipe

threads, connect system tting. A

leak-tight 3/4 inch NPT tting joint

should be obtained by applying

minimum-to-maximum torque of

10 to 20 lb-ft (13,4 to 26,8 N·m).

Higher levels of torque can distort

the Fitting inlet with consequent

leakage of Fitting or impairment of

Nozzle.

•

Socket-Weld Fitting Installations

(Figure 2) - Insert prepared end of

3/4 Inch system pipe into IFP Fitting

weld socket until fully engaged.

Weld full circumference of pipe at

juncture with face of IFP Fitting

weld socket.

Care and

Maintenance

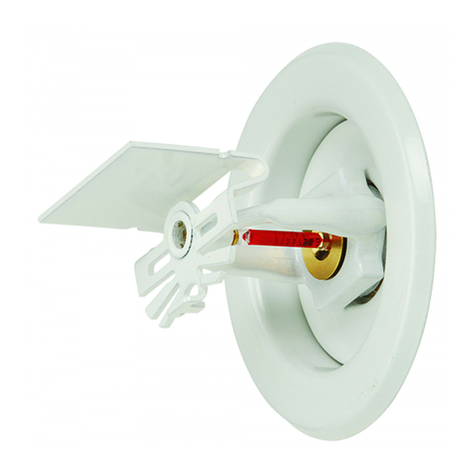

The TYCO Type IFP AQUAMIST

Recessed Nozzle Fittings must be

maintained and serviced in accordance

with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

system from the proper authorities

and notify all personnel who may be

affected by this action.

Type IFP AQUAMIST Recessed Nozzle

Fittings must never be painted, plated,

coated or altered in any way after

leaving the factory; otherwise, the

spray performance may be impaired.

Care must be exercised to avoid

damage to the nozzles -before, during,

and after installation. Nozzles damaged

by dropping, striking, wrench twist/slip-

page, or the like, must be replaced.

Frequent visual inspections are rec-

ommended to be initially performed

for nozzles installed in potentially cor-

rosive atmospheres to verify the integ-

rity of the materials of construction and

finish as they may be affected by the

corrosive conditions present for a given

installation. Thereafter, annual inspec-

tions per NFPA 25 are required.

The owner is responsible for the inspec-

tion, testing, and maintenance of their

fire protection system and devices in

compliance with this document, as well

as with the applicable standards of the

NATIONAL FIRE PROTECTION ASSO-

CIATION (e.g., NFPA 25), in addition to

the standards of any other authorities

having jurisdiction. Contact the install-

ing contractor or nozzle manufacturer

with any questions.

Water spray fixed systems should be

inspected, tested, and maintained by

a qualified Inspection Service in accor-

dance with local requirements and/or

national codes

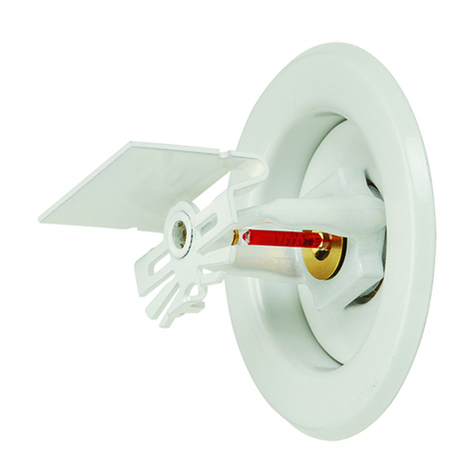

If the Cap does not remain in place on

the Fitting, it is recommended that the

Link/Cap Subassembly be replaced.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indicate

the full product name and Part Number

(P/N).

Type AM31 Nozzle with NPT

Threaded IFP Fitting and

Cap Assembly

Specify: Type AM31 AQUAMIST Nozzle

with NPT Threaded IFP Fitting and Cap

Assembly, Stainless Steel, P/N 28227

Type AM31 Nozzle with Socket-

Weld IFP Fitting and Cap Assembly

Specify: Type AM31 AQUAMIST Nozzle

with Socket-Weld IFP Fitting and Cap

Assembly, Stainless Steel, P/N 28228

Type AM31 Nozzle with NPT

Threaded IFP Fitting and Dust Cap

Assembly

Specify: Type AM31 AQUAMIST Nozzle

with NPT Threaded IFP Fitting and Flu-

orosilicone Dust Cap, Stainless Steel,

P/N 28251

Type AM31 Nozzle with Socket-

Weld IFP Fitting and Dust Cap

Assembly

Specify: Type AM31 AQUAMIST Nozzle

with Socket-Weld IFP Fitting and Flu-

orosilicone Dust Cap, Stainless Steel,

P/N 28252

Type AM10 Nozzle with NPT

Threaded IFP Fitting and

Cap Assembly

Specify: Type AM10 AQUAMIST Nozzle

with NPT Threaded IFP Fitting and Cap

Assembly, Stainless Steel, P/N 28242

Type AM10 Nozzle with Socket-

Weld IFP Fitting and Cap Assembly

Specify: Type AM10 AQUAMIST Nozzle

with Socket-Weld IFP Fitting and Cap

Assembly, Stainless Steel, P/N 28243

Sprinkler Wrench

Specify: W-Type 29 Sprinkler Wrench,

P/N 28241

REPLACEMENT PARTS

Link/Cap Subassembly

Specify: Link/Cap Subassembly, Stain-

less Steel, P/N 000028230

Type AM31 AQUAMIST Nozzles

Specify: Type AM31 AQUAMIST

Nozzle, Stainless Steel finish, P/N

28229

Type AM10 AQUAMIST Nozzles

Specify: Type AM10 AQUAMIST Nozzle,

Stainless Steel, P/N 49-207-0-001

Dust Cap Assembly

Specify: Model F885 Dust Cap Assem-

bly, Fluorosilicone, with Stainless Steel

Wire, P/N 28247*

*Refer to Technical Data Sheet TFP2299 for installation

instructions.