Model TY720

16.8 K-factor Pendent Sprinkler

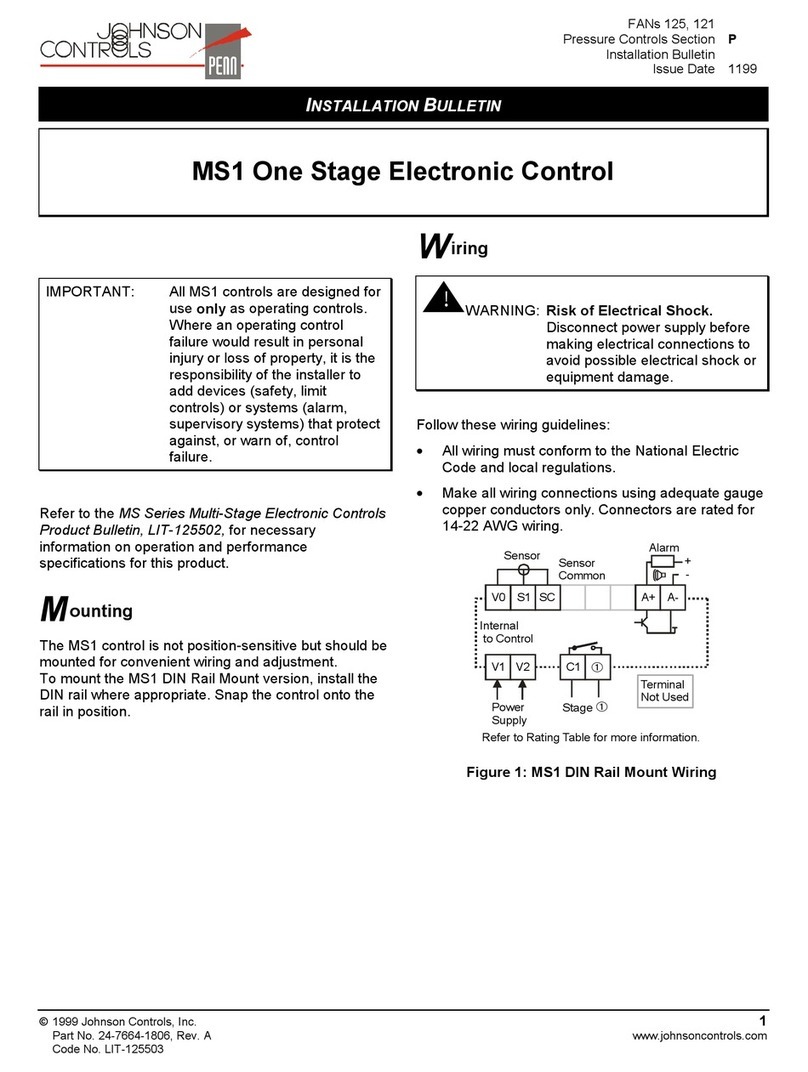

Electronic Control

Page 1 of 2 MARCH 2019 TFP325

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

General

Description

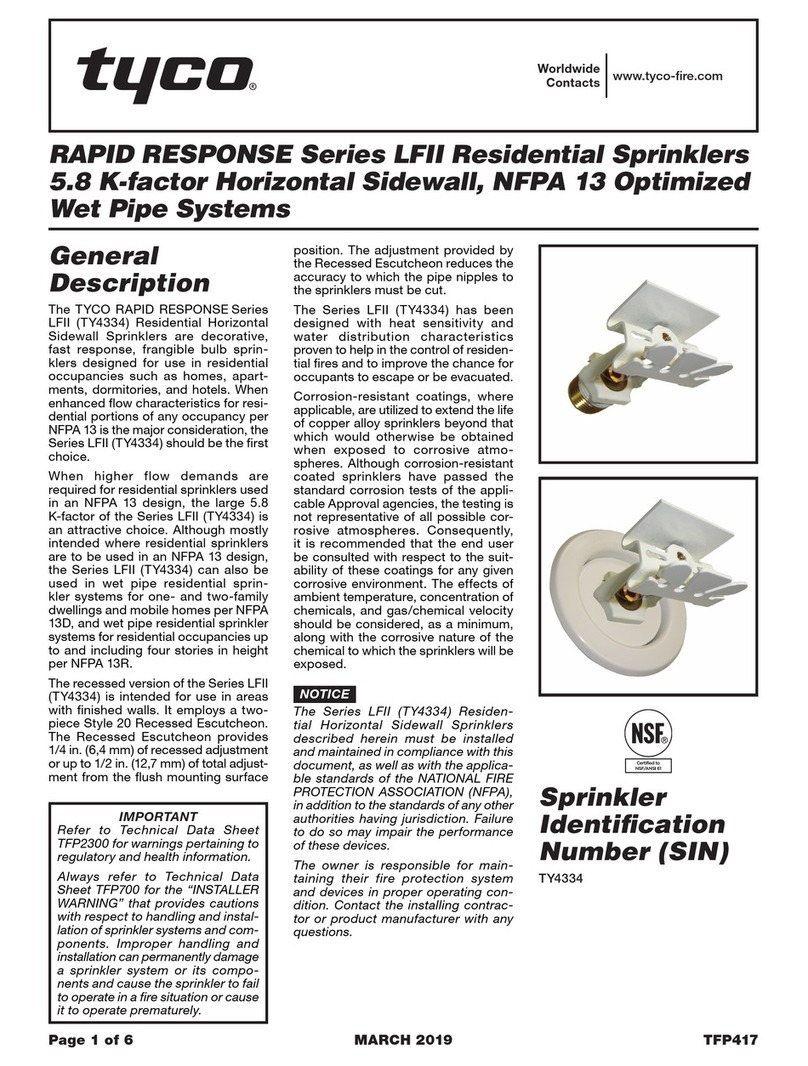

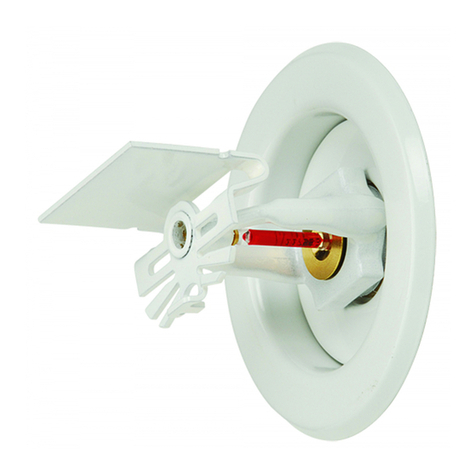

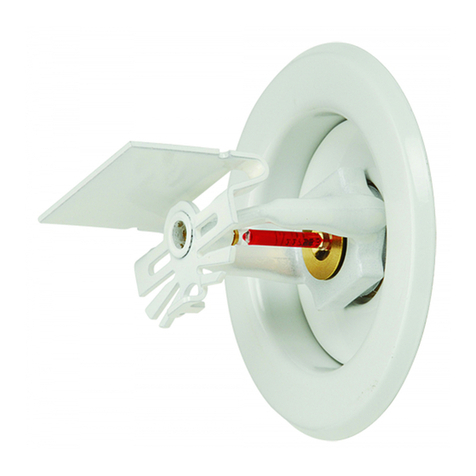

The TYCO Model TY720 Pendent

Sprinkler is an electronically controlled

sprinkler having a nominal K-factor of

16.8, see Figure 1.

The TY720 sprinkler is designed as an

integral component of the EAS-1 Elec-

tronically Activated Sprinkler System

for Storage Applications, a perfor-

mance-based system addressing

highly challenging high pile storage fire

hazards. For more information about

the sprinkler system and the system

components, refer to technical data

sheet TFP360.

In place of a traditional heat-sensi-

tive glass bulb or solder element, the

TY720 sprinkler features an electronic

linear actuator and tensile link with

hook and strut arrangement holding a

button and seal against the waterway.

An AUTOPULSE Sprinkler Control Heat

Sensor paired with the TY720 sprinkler

is connected directly to the actuator

and is in continuous communication

with an AUTOPULSE EAS-1 Control

Unit.

The control unit software algorithm

analyzes information from heat sensors

in multiple locations and selects the

optimal response in a fire event. An

electrical pulse is then delivered from

an algorithm-selected heat sensor to

its companion TY720 sprinkler, oper-

ating the actuator and breaking the

tensile link, allowing waterflow from

the sprinkler.

NOTICE

The TY720 Sprinkler described herein

must be installed and maintained in

compliance with this document, as

well as with the applicable standards

of the National Fire Protection Associa-

tion, in addition to the standards of any

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Sprinkler

Identification

Number (SIN)

TY720

Technical

Data

Approvals

UL and C-UL Listed

Maximum Working Pressure

175 psi (12,1 bar)

Pipe Thread Connections

3/4 in. NPT

Discharge Coefficient

K=16.8 GPM/psi½(241,9 LPM/bar½)

Finish

Natural Brass

Physical Characteristics

Frame .............................Brass

Deflector. . . . . . . . . . . . . . . . . . . . . . . . . . Bronze

Compression Screw . . . . . . . . . . Stainless Steel

Hook.............................MONEL

Strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MONEL

Tensile Link . . . . . . . . . . . . . . . . . . . . . . . Copper

Button.............................Brass

Sealing Assembly . Beryllium Nickel w/TEFLON

Ejection Spring. . . . . . . . . . . . . . . . . . . INCONEL

Electrical Actuator . . . . . . . . . . . . . . . . . . . Brass

Electrical Actuator Housing.....ABS/PC Resin

Temperature Rating

Temperature rating is determined by

the control unit and heat sensor paired

with the TY720 sprinkler.

For more information, refer to EAS-1

Electronically Activated Sprinkler

System for Storage Applications (Tech-

nical Data Sheet TFP360).

Installation

Install the Model TY720 Pendent Sprin-

kler in accordance with this section.

General Instructions

Take care handling the sprinkler during

installation to avoid damage to the

actuator and tensile link. Hold the

sprinkler by the frame and wrench flats,

and do not grasp the actuator, when

hand-tightening into position.

A leak-tight 3/4 in. NPT sprinkler joint

should be obtained by applying pipe-

thread sealant to the sprinkler threads

and wrench-tightening using only

the W-Type 21 Sprinkler Wrench, see

Figure 2.

Sprinkler Installation

Install the Model TY720 Pendent Sprin-

kler only in the pendent position as

follows:

Step 1. Apply pipe-thread sealant to

sprinkler threads.

Step 2. Hold the sprinkler by the frame

and wrench flats, and do not grasp or

apply force to the actuator and tensile

link. Insert and hand-tighten the sprin-

kler into the sprinkler fitting.