Johnson Health Tech. Co., Ltd.

Abstract

Abstract

1. Product specification

2. Engineering mode introduction

2-1. Motor testing (P1) 2-2. Sensor testing (P2) 2-3. Current testing (P3)

2-4. Air pressure testing (P4) 2-5. Software version detection model (PU)

3. Anomaly codes

3-1. OF, 90 3-2. A0 3-3. A1 3-4. A2, A3, B0, B1

3-5. B2, B3, C0, C1 3-6. D0 3-7. E0 3-8. E1, E2

4.Common troubleshooting

4.1 Fail to start 4.2 Pushrod motor 4.3 Speaker

4.4 Single air bag 4.5 All air bags 4.6 Warm

4.7 Machine core 4.8 Failure of armrest keyboard shortcuts 4.9 Chair back reclines once the machine is started

4.10 Abnormal up and down of the machine core

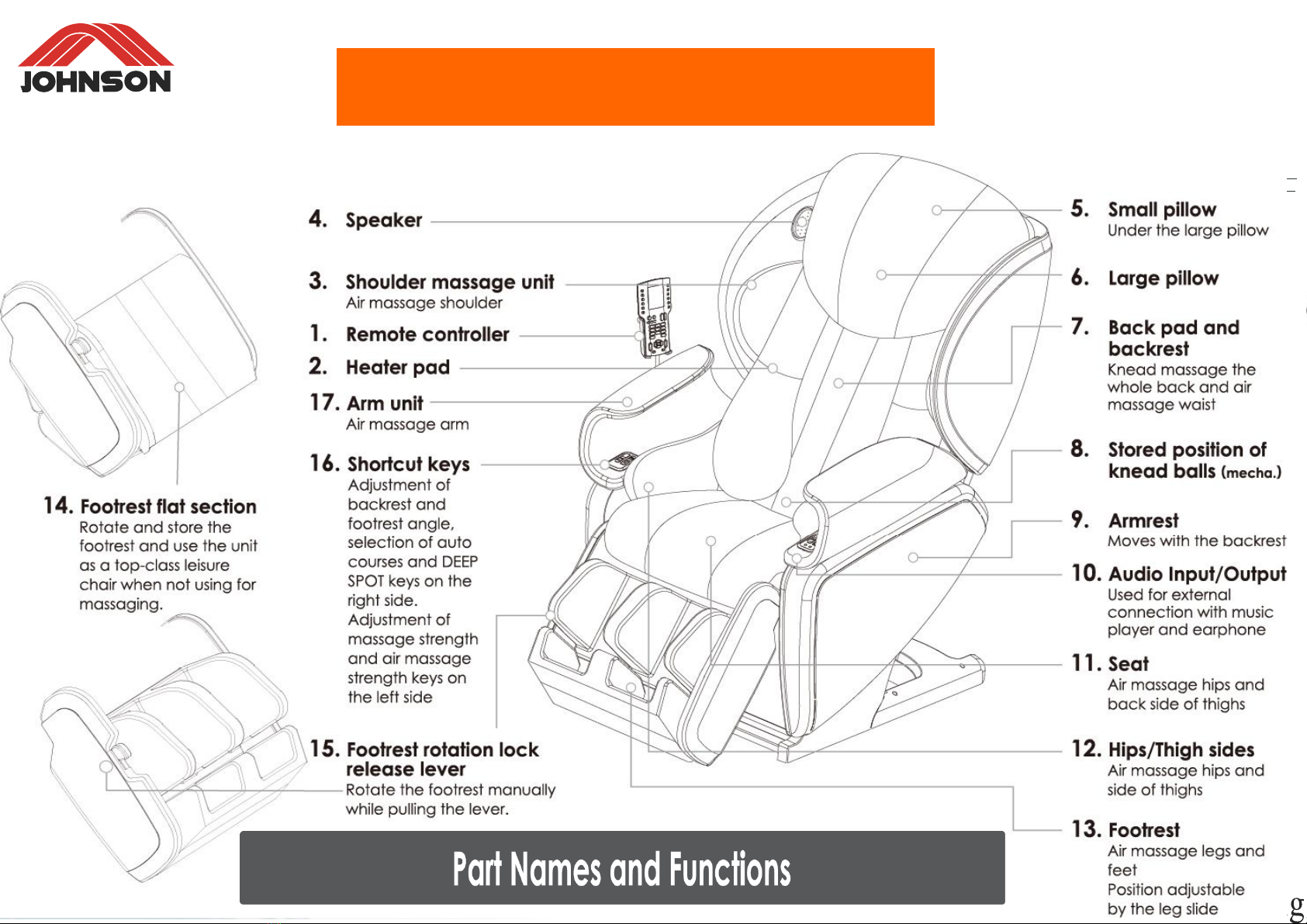

5. Appendices

5.1 Replace the machine core 5.2 Software update 5.3 Adjust machine core motor current

5.4 Complete machine breakdown drawing 5.5 Machine core breakdown drawing

5.6 Lower control panel breakdown drawing

Thank you! (Contact us)