Content

CHAPTER 1:PRODUCT SPECIFICATIONS----------------------------------------------------------------- 1

CHAPTER 2:MAINTENANCE AND STORAGE------------------------------------------------------------- 4

CHAPTER 3:ENGINEERING MODE INSTRUCTION------------------------------------------------------5

3.1 Key Operation:---------------------------------------------------------------------------------------------5

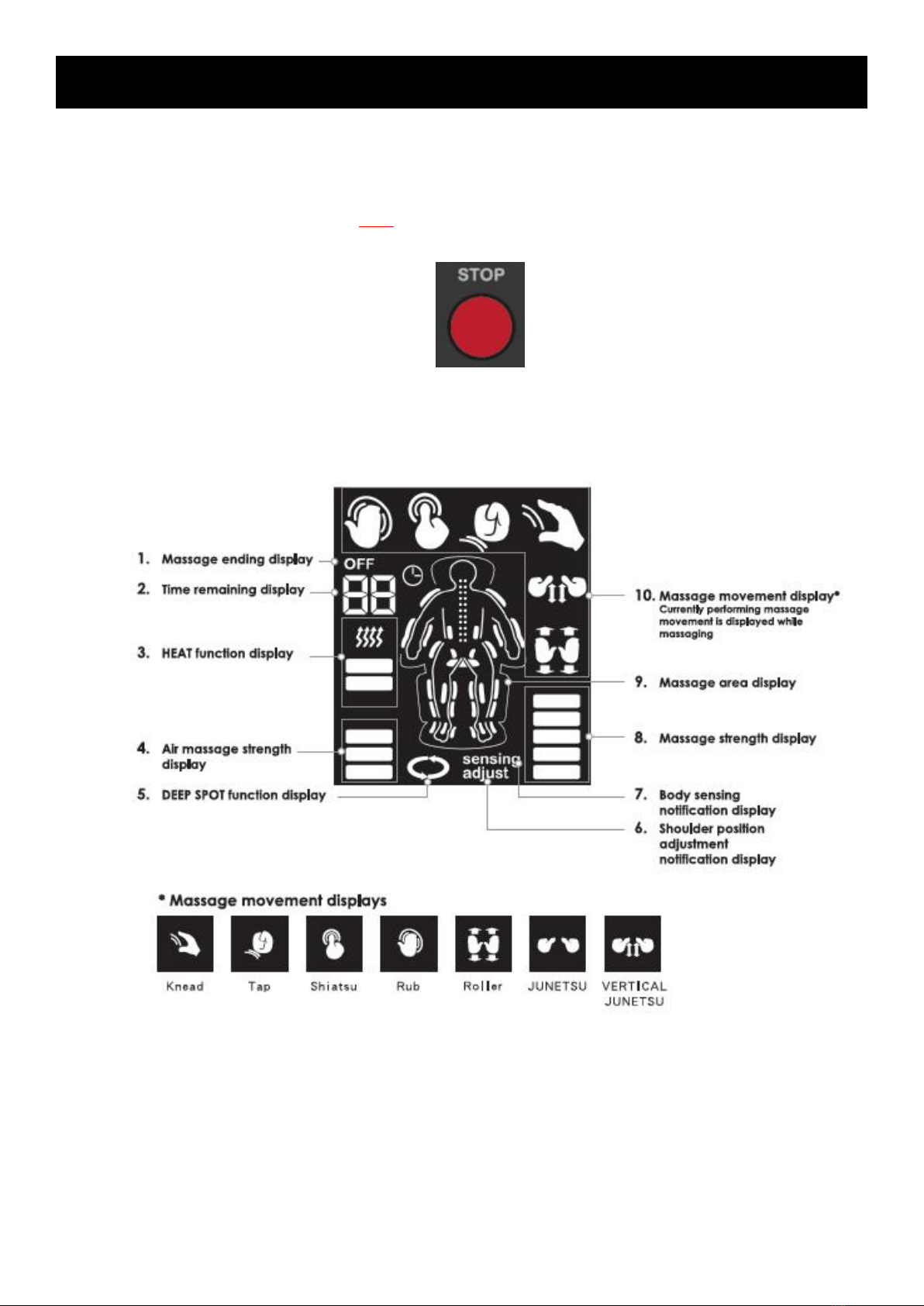

3.2 Display Information:-------------------------------------------------------------------------------------- 7

3.3 P1 Mode:---------------------------------------------------------------------------------------------------- 8

3.4 P2 Mode----------------------------------------------------------------------------------------------------- 9

3.5 P3 Mode--------------------------------------------------------------------------------------------------- 10

3.6 P4 Mode--------------------------------------------------------------------------------------------------- 11

3.7 PU Mode---------------------------------------------------------------------------------------------------12

CHAPTER 4:ERROR CODE------------------------------------------------------------------------------------ 13

CHAPTER 5:TROUBLESHOOTING-------------------------------------------------------------------------- 14

5.1 Wiring Schematic----------------------------------------------------------------------------------------14

5.2 Fail To Start----------------------------------------------------------------------------------------------- 16

5.3 Fail To Start - Continue-------------------------------------------------------------------------------- 17

5.4 Pushrod Motor Does Not Work---------------------------------------------------------------------- 19

5.5 Speak Has No Sound---------------------------------------------------------------------------------- 19

5.6 Individual Air Bag Can Not Be Inflated Or Inflated Sufficiently------------------------------19

5.7 All Air Bags Do Not Work----------------------------------------------------------------------------- 19

5.8 Abnormal Warming Function------------------------------------------------------------------------- 20

5.9 Machine Core Motor Does Not Work-------------------------------------------------------------- 22

5.10 Abnormal Key Function------------------------------------------------------------------------------ 23

5.11 Chair Back Reclines Abnormally------------------------------------------------------------------ 24

5.12 Machine Core Movement Issue--------------------------------------------------------------------24

5.13 E5 Error Code------------------------------------------------------------------------------------------ 26

CHAPTER 6:PARTS REPLACEMENT----------------------------------------------------------------------- 32

6.1 Air Pump--------------------------------------------------------------------------------------------------- 32

6.2 Machine Core-------------------------------------------------------------------------------------------- 35

6.3 Master Control Panel----------------------------------------------------------------------------------- 40

6.4 Footrest---------------------------------------------------------------------------------------------------- 41

6.5 Software Update-----------------------------------------------------------------------------------------44

6.6 Machine Breakdown Drawing------------------------------------------------------------------------ 45

CHAPTER 7:PARTS LIST--------------------------------------------------------------------------------------- 46