i

CONTENTS

!. SPECIFICATIONS ..........................................................................................................1

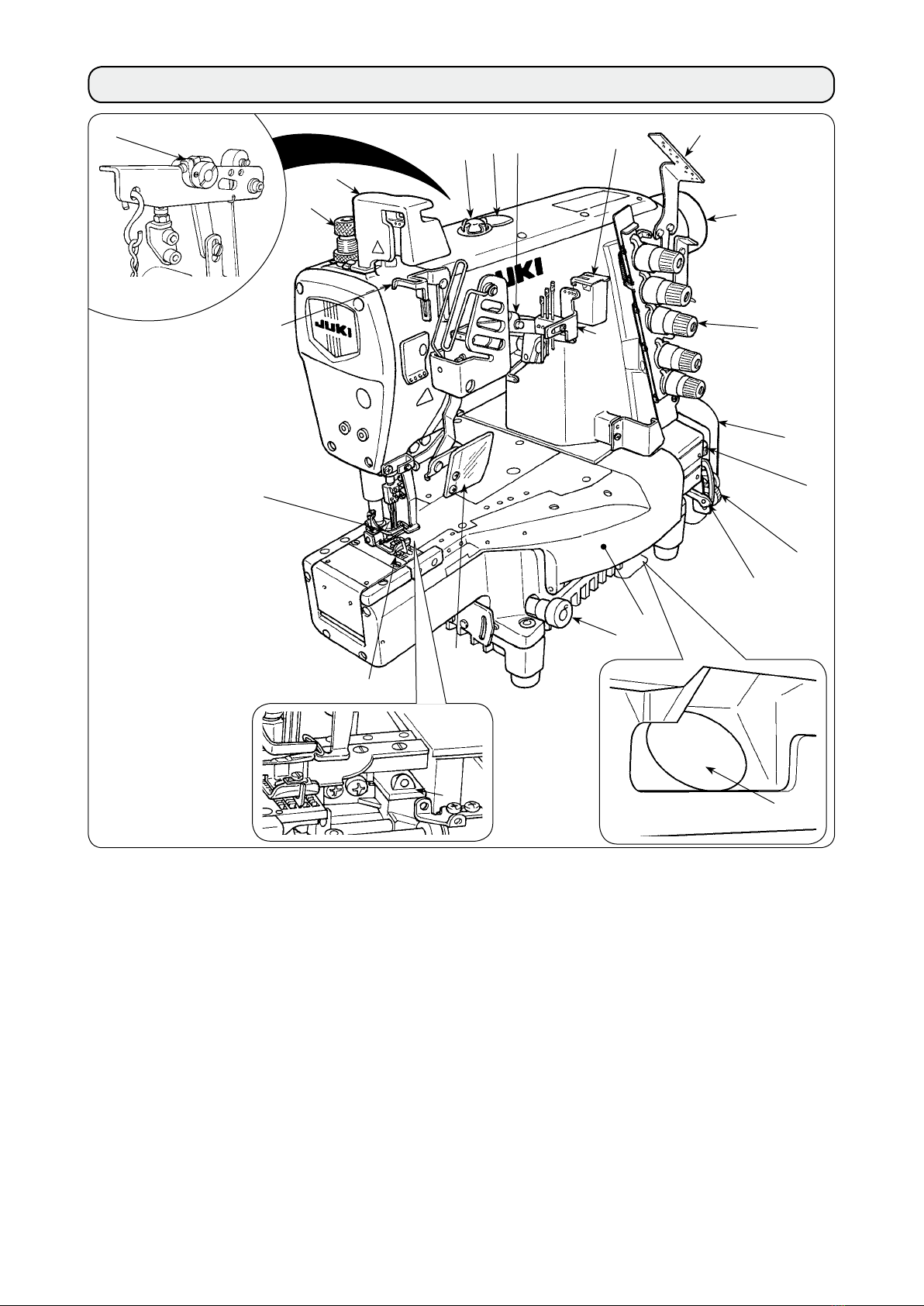

@. CONFIGURATION OF THE MACHINE COMPONENTS ...............................................2

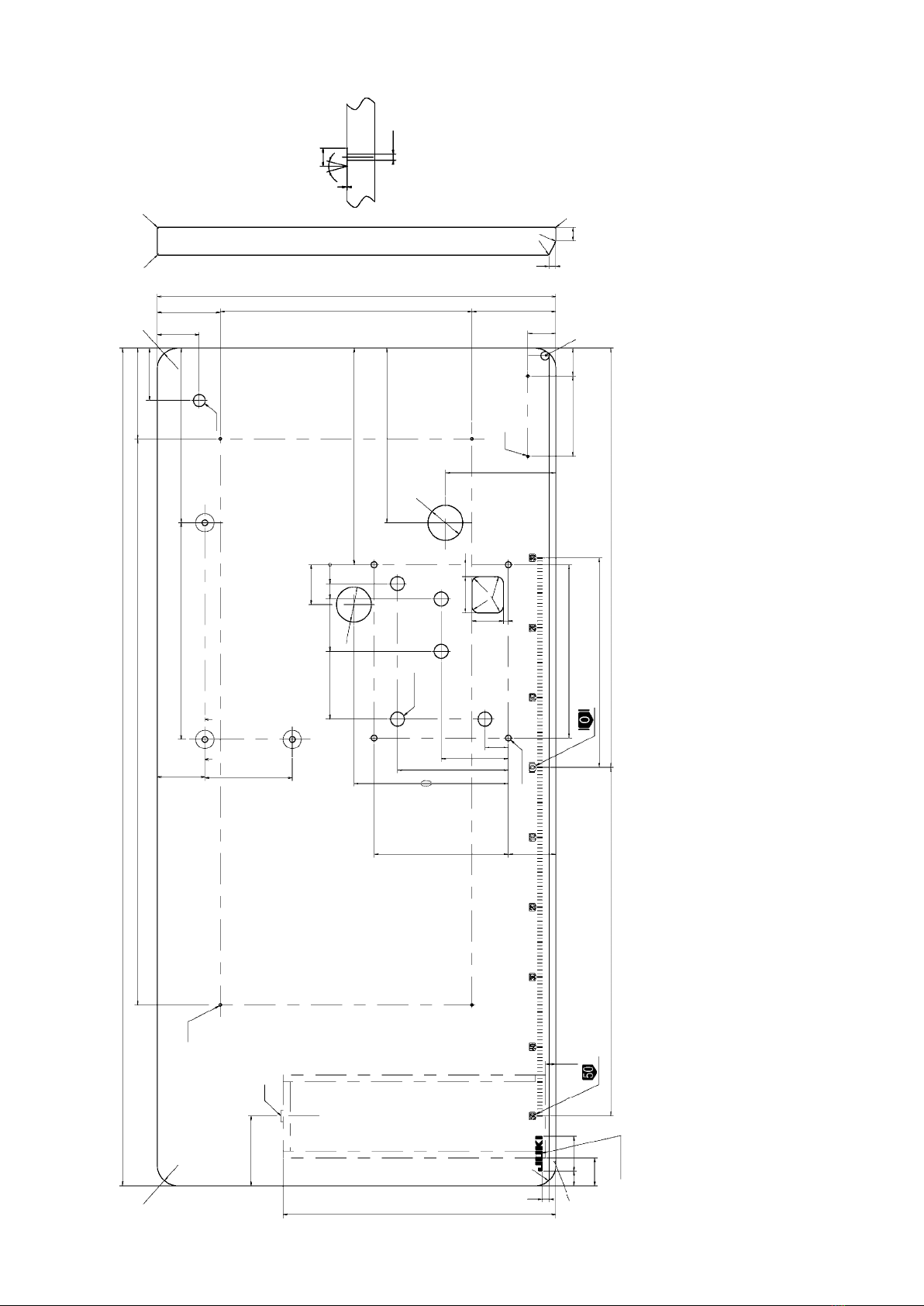

#. INSTALLATION ..............................................................................................................3

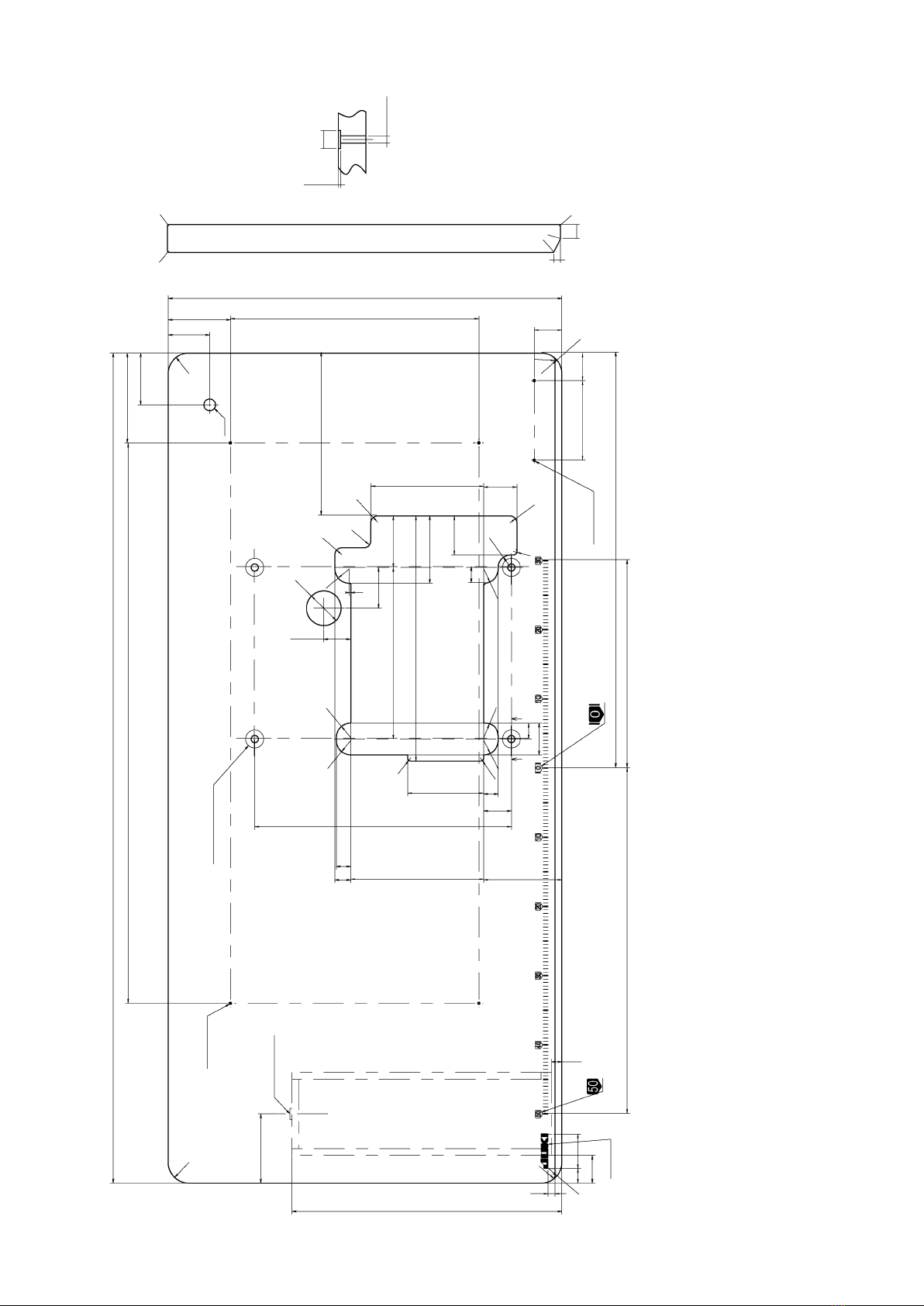

1. Installing the machine head onto the table ........................................................................... 3

2. Selecting the motor pulley and the belt................................................................................. 9

3. Installing the motor.................................................................................................................. 9

4. Setting the belt ........................................................................................................................ 9

5. Installing the belt cover......................................................................................................... 10

6. Installing the chain ................................................................................................................ 10

7. Installing the thread guide .................................................................................................... 10

8. Installing the needle bar thread take-up cover ................................................................... 11

$. LUBRICATION AND OILING .......................................................................................11

1. Lubricating oil ........................................................................................................................ 11

2. Oiling....................................................................................................................................... 11

3. Silicon oil lubricating unit..................................................................................................... 12

%. OPERATION.................................................................................................................12

1. Needle ..................................................................................................................................... 12

2. Attaching the needle.............................................................................................................. 12

3. Threading the machine head ................................................................................................ 13

(1) Standard threading .................................................................................................................. 13

4. Adjusting the stitch length.................................................................................................... 14

5. Adjusting the differential feed ratio ..................................................................................... 14

6.

Adjusting the presser foot pressure......................................................................................... 15

7. Adjusting the thread tension ................................................................................................ 15

^.

ADJUSTING THE SEWING MACHINE.......................................................................................16

1. Adjusting the silicon container thread guide...................................................................... 16

2. Adjusting the needle bar thread take-up thread receiver .................................................. 16

3. Adjusting the rocking thread take-up .................................................................................. 17

4. Adjusting the spreader thread guide ................................................................................... 17

5. Adjusting the looper thread cam thread guide and the looper thread cam ..................... 17

6. Adjusting the looper .............................................................................................................. 18

7. Adjusting the height of the needle ....................................................................................... 18

8.

Adjusting the rear needle guard.................................................................................................................19

9. Relation between the rocking thread take-up timing and the needle thread loop ..............19

(1) Adjustment by the crank ......................................................................................................... 19

(2) Adjustment by the eccentric cam ........................................................................................... 20

10. Adjusting the height of the feed dog ................................................................................... 21

11. Installing position of the spreader ....................................................................................... 21

12. Adjusting the spreader thread guide and the needle clamp thread guide....................... 22

13. Adjusting the front needle guard ......................................................................................... 22

14. Adjusting the presser foot lift............................................................................................... 23

15. Adjusting the micro-lifter ...................................................................................................... 23

16. Adjusting the feed locus ....................................................................................................... 24

(1) Retarding the feed driving motion.......................................................................................... 24

(2) Retarding the feed rocking motion......................................................................................... 25

17. Adjustment value of balloon................................................................................................. 26

&. MAINTENANCE ...........................................................................................................28

1. Cleaning the sewing machine............................................................................................... 28

2. Replacing the lubricating oil ................................................................................................ 28

3. Inspectingandreplacingtheoillter .................................................................................. 28