IM 04L21B01-03EN page 1/4

Introduction

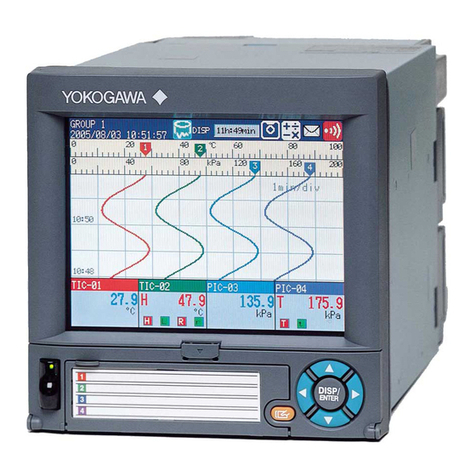

Thank you for purchasing the FX1002, FX1004, FX1006, FX1008, FX1010, or FX1012 Paperless

Recorder (hereafter referred to as “FX” or “FX1000”.). This manual describes the safty precautions

and installation and wiring procedures of the FX1000.

To ensure correct use, please read this manual and the manuals below thoroughly before

beginning operation. For the product specications, see the general specications.

Paper Manual

Manual Title Manual No.*

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder Safety Precautions and Installation Guide

Installing the FXA120 DAQSTANDARD

FX1000 Mode Transition Diagram

Setting Mode / Basic Setting Mode Maps (This manual)

IM 04L21B01-03EN

Electronic Manuals

You can download these manuals from the following web page. You will need Adobe Reader 7 or

later (latest version recommended) by Adobe Systems.

http://www.yokogawa.com/ns/fx1000/im/

Manual Title Manual No.*

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder User’s Manual

IM 04L21B01-01EN

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder First Step Guide

IM 04L21B01-02EN

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder Safety Precautions and Installation Guide

Installing the FXA120 DAQSTANDARD

FX1000 Mode Transition Diagram

Setting Mode / Basic Setting Mode Maps

IM 04L21B01-03EN

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder Communication Interface (/C2, /C3, and /C7)

IM 04L21B01-17EN

FXA120 DAQSTANDARD for FX1000 Data Viewer IM 04L21B01-63EN

FXA120 DAQSTANDARD for FX1000 Hardware Configurator IM 04L21B01-64EN

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder Usage Precautions

IM 04L21B01-91EN

General Specications (GS)

General Specifications Name General Specifications No.*

Model FX1002/FX1004/FX1006/FX1008/FX1010/FX1012

FX1000 Paperless Recorder

GS 04L21B0-02EN

* The last two characters of the manual number and the general specications number indicate

the language in which the manuals or general specications are written.

The Authorised Representative for this product in the EEA is:

Yokogawa Europe B.V.

Euroweg 2, 3825 HD Amersfoort,The Netherlands

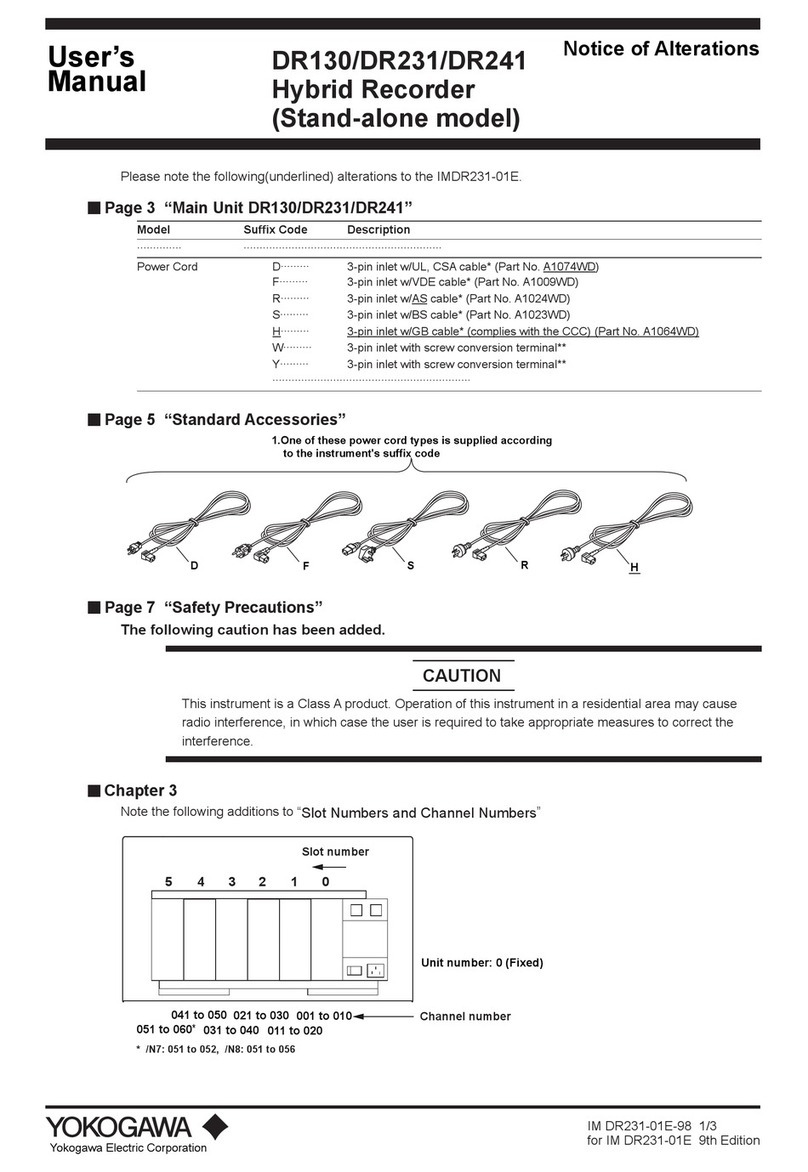

Model and Sufx Codes

A name plate is located on the top panel of the FX. Check that the model name and sufx code

given on the name plate match those on your order.

Model

code

Suffix code

Optional

code

Description

FX1002

2ch, Shortest measurement interval:125ms

FX1004

4ch, Shortest measurement interval:125ms

FX1006 6ch, Shortest measurement interval:1s

FX1008 8ch, Shortest measurement interval:1s

FX1010

10ch, Shortest measurement interval:1s

FX1012

12ch, Shortest measurement interval:1s

External

storage

medium

slot

-0 Without CF card slot/SD card slot and medium

(Note)

-4 With CF card slot and medium

-7 With SD card slot and medium

Language -2

English/German/French/Italian/ Spanish/

Portuguese/ Russian/ Korean

deg F and DST

Withstanding

voltage between

measuring input

terminals

-H 1000 VAC(50/60 Hz), 1 min

-L 400 VAC(50/60 Hz), 1 min

Options /A1 Alarm output 2 points (C-contact)*1*10

/A2 Alarm output 4 points (C-contact)*1

/A3 Alarm output 6 points (C-contact)*1*3

/A4A Alarm output 12 points (A-contact)*1*3

/C2 RS-232 interface*2

/C3 RS-422A/485 interface*2

/C7 Ethernet interface

/F1 FAIL/Status output*3

/M1

Mathematical functions (including Report functions)

/N2 3 leg isolated RTD*4

/N3F Extended input type (without Pt1000)

/P1 24 VDC/AC power supply

/R1 Remote control 8 points*5

/TPS2 24VDC transmitter power supply (2 loops)*6*10

/TPS4 24VDC transmitter power suply (4 loops)*7

/USB1 USB interface (1 port)

/PM1 Pulse input 3 points, Remote control 5 points

(including Mathematical functions)*8

/CC1 Calibration correction function

/LG1 Log scale

/PWR1 Power monitor (1 A input, including Mathmatical

functions)*9*10

/PWR5 Power monitor (5 A input, including Mathmatical

functions)*10*11

/S# Customized product; details in IM FX1K-S#E*12

Note: To load data, the FX must be equipped with a communication interface (/C2, /

C3 or /C7 option) or the USB interface (/USB1 option.)

*1 Any combination of /A1, /A2, /A3, and /A4A cannot be specied together.

*2 /C2 and /C3 cannot be specied together.

*3 /A3 or /A4A cannot be specied together with /F1.

*4 /N2 cannot be specied for FX1002 or FX1004.

*5 If /R1 is specied, /A4A, /TPS2, /TPS4, /PM1, /PWR1, or /PWR5 cannot be specied.

*6 If /TPS2 is specied, /TPS4, /A2, /A3, /A4A, /F1, /R1, or /PM1 cannot be specied.

*7 If /TPS4 is specied, /TPS2, /A1, /A2, /A3, /A4A, /F1, /R1, or /PM1 cannot be specied.

*8 If /PM1 is specied, /A4A, /M1, /R1, /TPS2, /TPS4, /PWR1, or /PWR5 cannot be specied.

*9 If /PWR1 is specified, /A3, /A4A, /F1, /R1, /PM1, /M1, or /PWR5 cannot be

specied.

*10 /TPS2, /PWR1, and /A1 cannot be specied together. /TPS2, /PWR5, and /A1

cannot be specied together.

*11 If /PWR5 is specied, /A3, /A4A, /F1, /R1, /PM1, /M1, or /PWR1 cannot be specied.

*12 Contact your supplier in case your instrument has option /S# (where ‘#’ is a

number), and you are not in the possession of IM FX1K-S#E.

Standard Accessories

The standard accessories below are supplied with the instrument. Check that all

contents are present and undamaged.

1 2

5

46

No. Name Model Qty. Notes

1 Mounting brackets B8730BU 2 For panel

mounting

2Rubber packing for dust and water

protection

- 1 For single-unit

mounting

4 Model FX1002/FX1004/FX1006/FX1008/

FX1010/FX1012

FX1000 Paperless Recorder Safety

Precautions and Installation Guide

Installing the FXA120 DAQSTANDARD

FX1000 Mode Transition Diagram

Setting Mode / Basic Setting Mode Maps

IM 04L21B01-

03EN

1 A3 size

5 CF card*1 772093 1 512 MB

6 SD card*2 773001 1 1 GB

*1 On FXs that have a CF card slot (sufx code -4.)

CF card capacity is subject to change.

*2 On FXs that have a SD card slot (sufx code -7.)

SD card capacity is subject to change.

*3 For optional accessories (Sold Separately), see the IM 04L21B01-02EN.

Softoware (FXA120 DAQSTANDARD for FX1000), Label

Please download the software and the label data from the following web page.

http://www.yokogawa.com/ns/fx1000/soft/

Item Description

Software FXA120 DAQSTANDARD for FX1000

Consists of the Data Viewer and the Hardware Configurator.

Label Labels to Attach to the FX1000 Operation Cover

Download the label data (Excel file). Print the label that you want to use.

Label size: 19 ± 0.3 mm tall and 90 ± 0.3 mm wide

File name: IM04L21B01-81Z1.xls

1. Safety Precautions

The following safety symbols are used on the product and in this manual.

Calls attention to actions or conditions that could cause serious

or fatal injury to the user, and indicates precautions that should be

taken to prevent such occurrences.

CAUTION

Calls attention to actions or conditions that could cause injury to

the user or damage to the instrument or property and indicates pre-

cautions that should be taken to prevent such occurrences.

Protective ground terminal

Alternating current

Direct current

“Handle with care.” To avoid injury and damage to

the instrument, the operator must refer to the

explanation in the manual.

Note

Identies important information required to operate the instrument.

nSafety Precautions

• This instrument conforms to IEC safety class I (provided with terminal for protec-

tive grounding), Installation Category II, and EN61326-1 (EMC standard), Mea-

surement Category II (CAT II)*.

* Measurement category II (CAT II) applies to measuring circuits connected to low voltage

installation, and electrical instruments supplied with power from fixed equipment such as

electric switchboards.

• This instrument is an EN61326-1 (EMC standard) class A instrument (for use in

commercial, industrial, or business environments). The inuence rate (judgment

condition A) in the immunity test environment is within ±15 % of the range or ±10

mV.

• The general safety precautions described here must be observed during all phases

of operation. If the FX is used in a manner not described in this manual, the FX

safety features may be impaired. Yokogawa Electric Corporation assumes no li-

ability for the customer’s failure to comply with these requirements.

• The FX is designed for indoor use.

n About User’s Manual

• Please pass user’s manuals to the end user. We also ask you to store manuals in

a safe place.

• Read user’s manuals thoroughly and have a clear understanding of the product

before operation.

• User’s manuals explain the functions of the product. It does not guarantee that the

product will suit a particular purpose of the user.

n

Precautions Related to the Protection, Safety, and Alteration of the Product

• For the protection and safe use of the product and the system in which this product

is incorporated, be sure to follow the instructions and precautions on safety that are

stated in this manual whenever you handle the product. Take special note that if you

handle the product in a manner that violates these instructions, the protection function-

ality of the product may be damaged or impaired. In such cases, YOKOGAWA does

not guarantee the quality, performance, function, and safety of product.

• When installing protection and/or safety circuits such as lightning protection devices

and equipment for the product and control system or designing or installing separate

protection and/or safety circuits for fool-proof design and fail-safe design of the pro-

cesses and lines that use the product and the control system, the user should imple-

ment these using additional devices and equipment.

• If you are replacing parts or consumable items of the product, make sure to use parts

specied by YOKOGAWA.

•

This product is not designed or manufactured to be used in critical applications that di-

rectly affect or threaten human lives. Such applications include nuclear power equipment,

devices using radioactivity, railway facilities, aviation equipment, air navigation facilities,

aviation facilities, and medical equipment. If so used, it is the user’s responsibility to in-

clude in the system additional equipment and devices that ensure personnel safety.

• Do not modify this product.

l Use the Correct Power Supply

Ensure that the source voltage matches the voltage of the power

supply before turning ON the power.

l Connect the Protective Grounding Terminal

Make sure to connect the protective grounding to prevent

electric shock before turning ON the power.

lDo Not Impair the Protective Grounding

Never cut off the internal or external protective grounding wire

or disconnect the wiring of the protective grounding terminal.

Doing so invalidates the protective functions of the instrument

and poses a potential shock hazard.

lDo Not Operate with Defective Protective Grounding

Do not operate the instrument if the protective grounding might

be defective. Also, make sure to check them before operation.

lDo Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable

liquids or vapors. Operation in such an environment constitutes

a safety hazard. Prolonged use in a highly dense corrosive gas

(H2S, SOx, etc.) will cause a malfunction.

l Do Not Remove Covers

The cover should be removed by YOKOGAWA’s qualified

personnel only. Opening the cover is dangerous, because some

areas inside the instrument have high voltages.

l Ground the Instrument before Making External Connections

Connect the protective grounding before connecting to the item

under measurement or control unit.

lDamage to the Protection

Operating the instrument in a manner not described in this

manual may damage the instrument’s protection.

This instrument is a Class A product. Operation of this instrument in a

residential area may cause radio interference, in which case the user is

required to take appropriate measures to correct the interference.

n Exemption from Responsibility

• YOKOGAWA makes no warranties regarding the product except those stated in

the WARRANTY that is provided separately.

• YOKOGAWA assumes no liability to any party for any loss or damage, direct or

indirect, caused by the user or any unpredictable defect of the product.

2. Installation

nInstallation Location

Install the FX indoors in an environment that meets the following conditions:

• Instrumentation Panel

The FX is designed to be installed in an instrumentation panel.

• Well-Ventilated Location

To prevent overheating, install the FX in a well-ventilated location. For the panel

cut dimensions when arranging multiple FXs, see “External Dimensions and Panel

Cutout Dimensions.” When other instruments are installed next to the FX, follow

the panel cut dimensions to provide adequate space around the FX.

• Minimal Mechanical Vibrations

Install the FX in a location that has minimal mechanical vibrations. Installing the FX

in a location that is subject to large levels of mechanical vibration will not only put

added stress on its components, it may also impede ordinary measurement.

• Level Location

Install the FX in a level location so that it is not slanted to the left or the right (how-

ever, the FX can be inclined up to 30 degrees backward for panel mounting).

Note

Condensation may form when moving the FX from an environment whose temperature or

humidity is low to an environment whose temperature or humidity is high, or when there

is a sudden change in temperature. Temperature or humidity changes may also result in

thermocouple measurement errors. In these kinds of circumstances, let the FX adjust to

the new environment for at least an hour before using it.

Do not install the FX in the following places.

• Outdoors

• In Direct Sunlight or Near Heat Sources

Install the FX in a place that is near room temperature (23°C) and that is not sub-

ject to large temperature uctuations. Placing the FX in direct sunlight or near heat

sources can cause adverse effects on the internal circuitry.

• Where an Excessive Amount of Soot, Steam, Moisture, Dust, or Corrosive

Gases Are Present

Soot, steam, moisture, dust, and corrosive gases will adversely affect the FX.

Avoid installing the FX in such locations.

• Near Strong Magnetic Field Sources

Do not bring magnets or instruments that produce electromagnetic elds close to the

FX. Operating the FX near strong magnetic elds can cause measurement errors.

• Where the Display Is Difcult to See

The FX uses an LCD screen, so it is difcult to view the display from an extreme

angle. Install the FX so that the user can view the display directly from the front.

nInstallation Procedure

Use a steel panel that is 2 mm to 26 mm thick.

1) Insert the FX through the front of the panel.

2)

Mount the FX to the panel using the included mounting brackets as shown in the gure below.

Installation

Guide

IM 04L21B01-03EN

Model FX1002/FX1004/FX1006

/FX1008/FX1010/FX1012

FX1000 Paperless Recorder

Safety Precautions and

Installation Guide

6th Edition : Nov. 2017