Art. No. SC 1000 KNX

The operation concept of an operating element on the push-button extension module can be

configured optionally in the ETS either as a rocker function or alternatively as a push-button

function. With the rocker function and the double-surface push-button function, the button

arrangement can be set either as "vertical" (top-bottom operation) or as "horizontal" (left-right

operation) for each control surface.

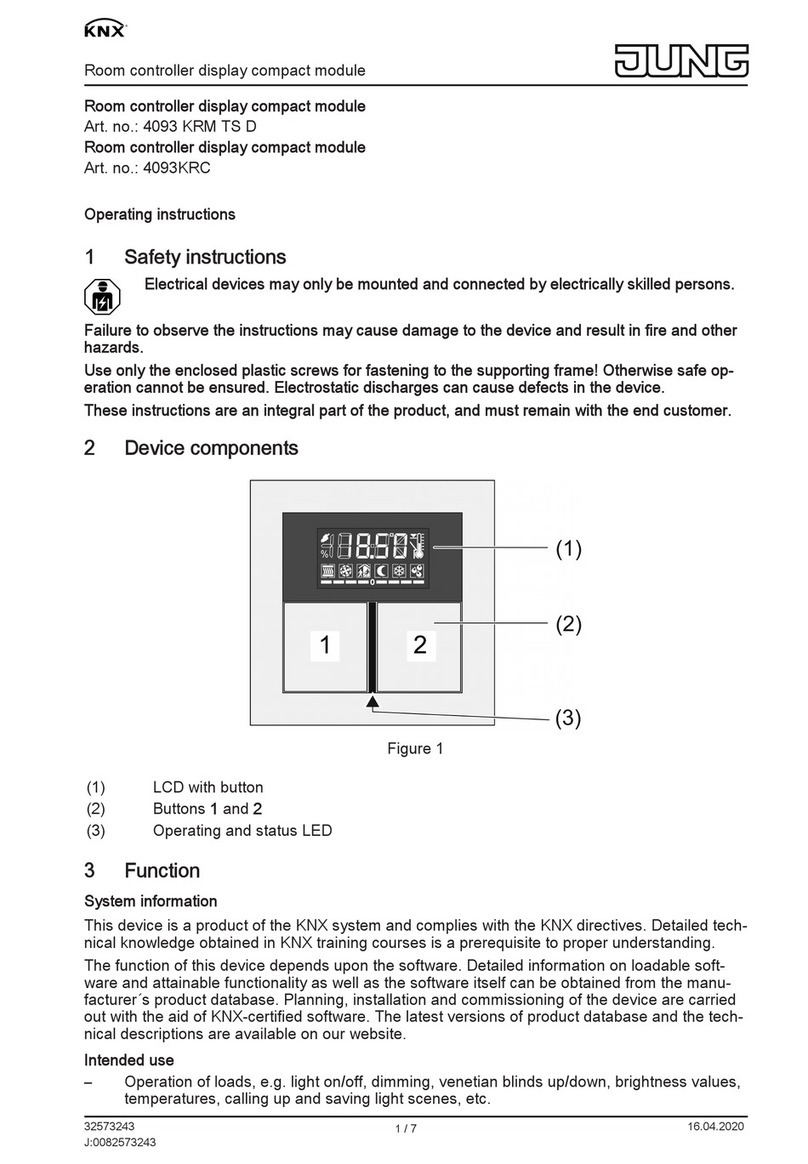

The device has a master button on the touch sensor surface outside the display area. The

master button can be linked to any existing KNX channel. In this way, a function, such as the

switching of room lighting, can be executed quickly and easily without touch operation of the

display pages. Two other sensor buttons make it easier to navigate through the display pages

(scrolling and returning to the start page) and can be used alternatively for finger operation of

the graphic interface.

Room temperature controller functionality:

The device can be used for single-room temperature control. Depending on the operating mode,

current temperature setpoint and room temperature, a variable for heating or cooling control can

be transmitted to the KNX for a control circuit. In addition to the heating or cooling basic level,

activating an additional heater and/or cooling unit means that an additional heating or cooling

unit can be used. In this connection, you can set the temperature setpoint difference between

the basic and the additional level by a parameter in the ETS. For major deviations between the

temperature setpoint and the actual temperature, you can activate this additional level to heat

up or cool down the room faster. You can assign different control algorithms to the basic and

additional stages.

For heating and cooling functions, you can select continuous or switching PI or switching 2-point

feedback control algorithms.

The room temperature can be recorded either by the internal or by an external KNX

temperature sensor (Temperature value via the bus). Combined temperature recording by both

sensors can also be configured.

The controller distinguishes between different operating modes (comfort, standby, night, frost/

heat protection) each with their own temperature setpoints for heating or cooling.

Display functionality:

Each operating element on the graphic screen can contain status elements. Status elements

can indicate, for example, whether a lighting system is switched on, which dimming value a

lighting system has or which height is set on a blind. Status elements can be displayed in

textual form (caption, value) as well as in symbolic form.

A header is arranged in the upper area (graphic horizon) in the device display. The current date

and room temperature of the location can be displayed in the header. On the start page, the

current time is also indicated in the display area. This display information can be hidden

separately if required.

The pushbutton extension module has two status LEDs, which, depending on the function of the

rocker or pushbutton, can be internally connected to the operating function or have its own

objects for controlling via the bus.

The graphic display lighting can be controlled. It can be switched on by means of an operation

or communication object. Switching off is possible either via the object or time-controlled.

Measured values of a KNX weather station can optionally be displayed on a separate display

page. Displayable values in this case are the wind speed, twilight threshold, external brightness

and temperature, precipitation situation, angle of the sun and up to any 4 different additional

external 2-byte values that can be formatted for display. The measured values are displayed by

symbols and text in a form adapted to the display concept.

Through the "ASCII Text" channel function, the device offers the possibility to output texts

received via the KNX Bus. For example, alarm messages or welcome messages can be shown

in the display.

General:

The device has a brightness sensor that measures the ambient lighting locally. The determined

brightness value can be compared with a configured limiting value. If values fall below or

exceed the limiting value, it is possible to transmit a switching telegram to the bus allowing

lighting to be triggered, for example.

A timer can optionally be activated. The timer, which is integrated in the device and can be

Page 5 of 347

Product definition