Kargo Master 80070 Datasheet

Other Kargo Master Automobile Accessories manuals

Kargo Master

Kargo Master 4081SF Manual

Kargo Master

Kargo Master 90001 User manual

Kargo Master

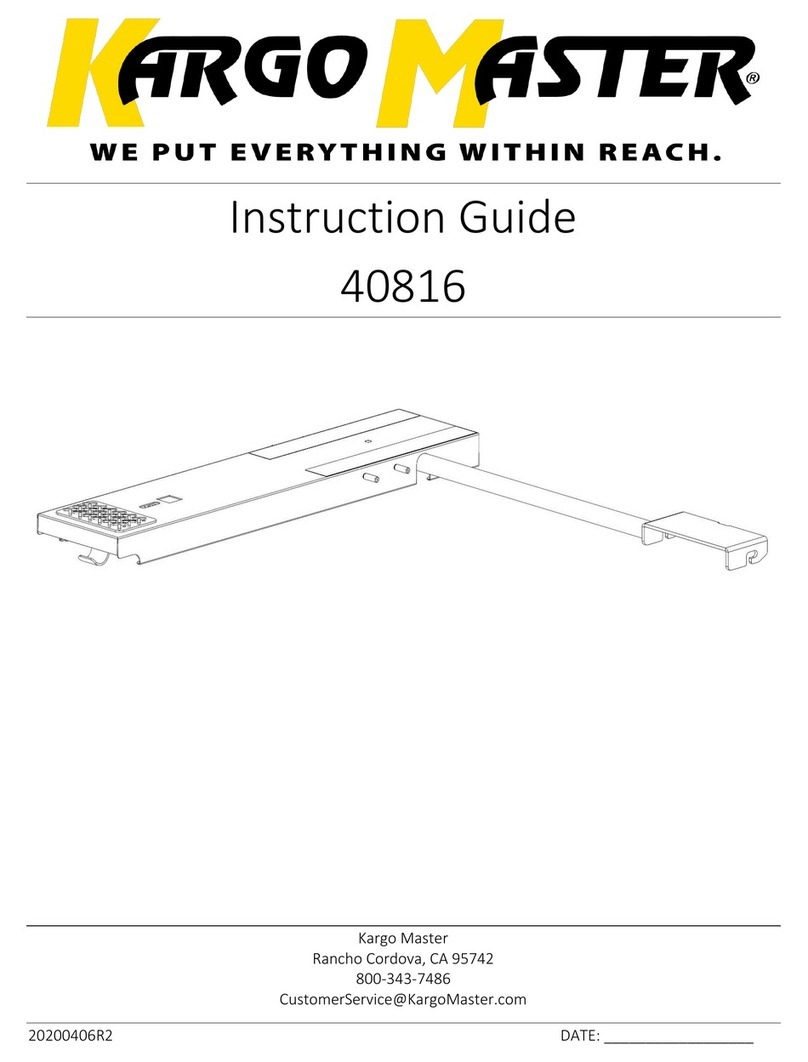

Kargo Master 40816 Manual

Kargo Master

Kargo Master 40933 Manual

Kargo Master

Kargo Master PRO-IV User manual

Kargo Master

Kargo Master 4090L Manual

Kargo Master

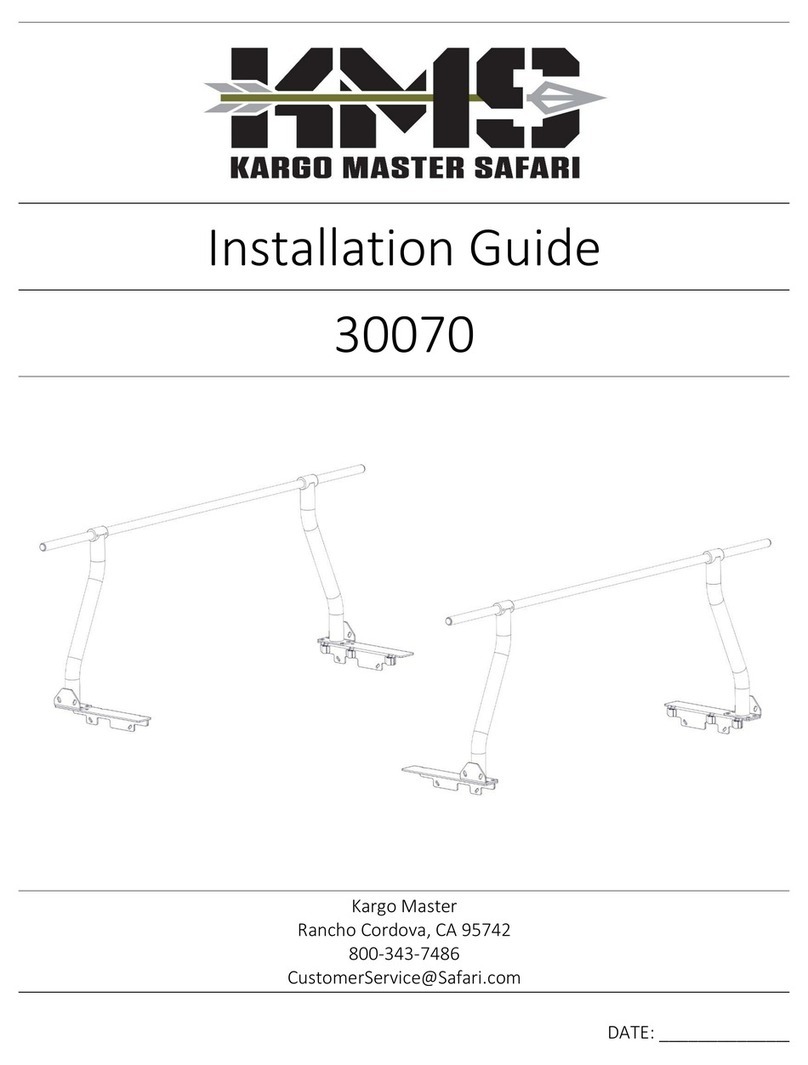

Kargo Master 30070 User manual

Kargo Master

Kargo Master 40680 User manual

Kargo Master

Kargo Master 40040 Manual

Kargo Master

Kargo Master 409CD User manual

Kargo Master

Kargo Master 4A98L-Rev 1 User manual

Kargo Master

Kargo Master 4081P User manual

Kargo Master

Kargo Master KILIMANJARO User manual

Kargo Master

Kargo Master 406GMF-P Manual

Kargo Master

Kargo Master 40813 User manual

Kargo Master

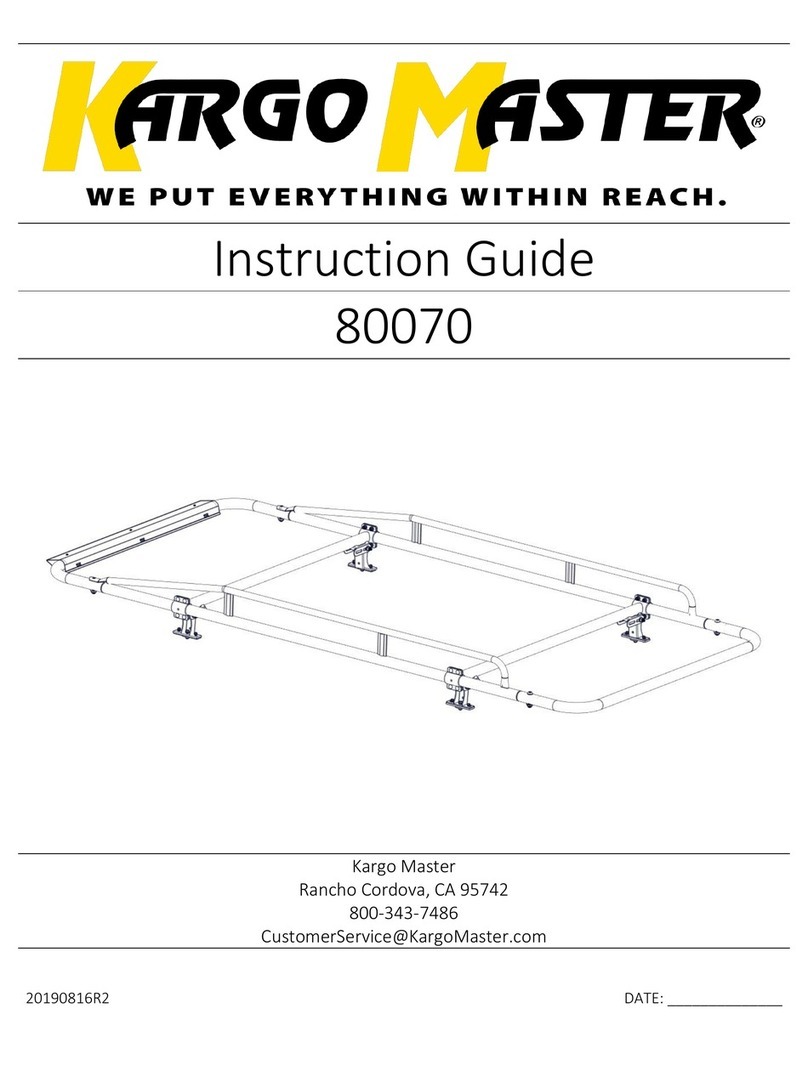

Kargo Master 80070 Manual

Kargo Master

Kargo Master 40110 User manual

Kargo Master

Kargo Master 4A95L User manual

Kargo Master

Kargo Master 4A92L User manual

Kargo Master

Kargo Master 40201 User manual