L

L

X

W

U

R

M

L

X

INSIDE BED WALL

REAR VIEW OF TRUCK

©2011 KARGO MASTER --KS_11_1.1

Outside of

Truck Bed

P

O

H

THAT'S IT!

You're ready to use and enjoy your

KARGO MASTER TRUCK RACK!

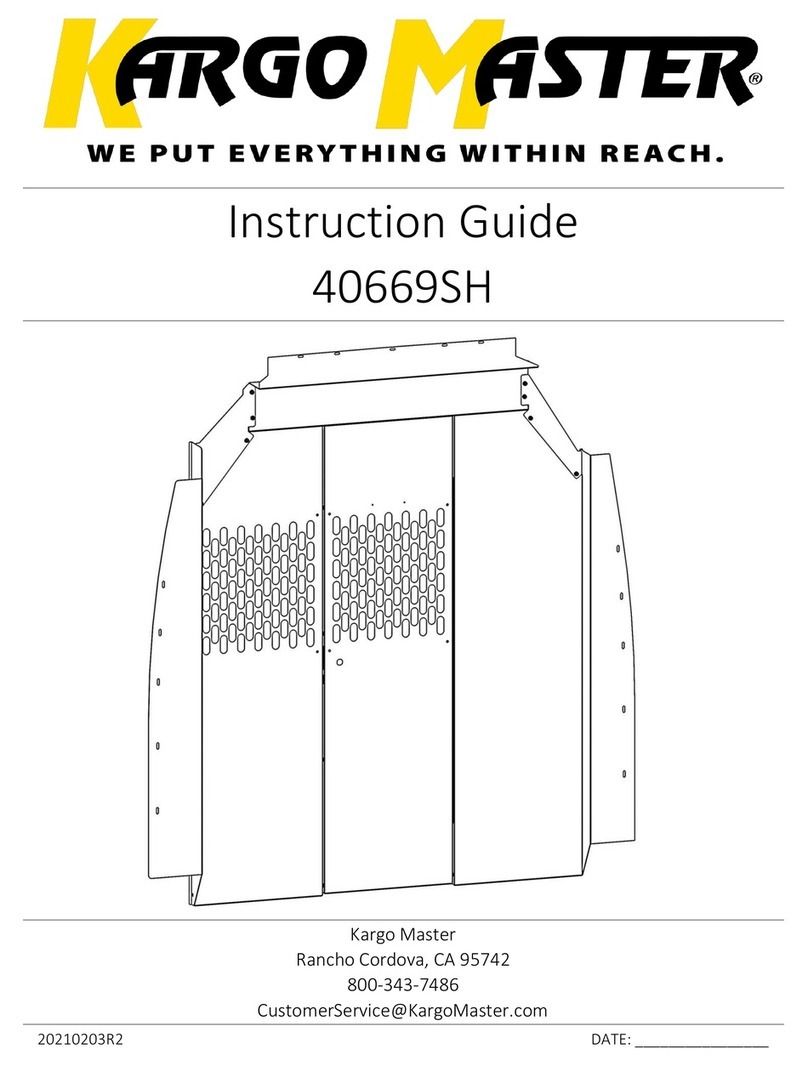

BULKHEAD

THROUGH

BOLT HOLE

3/8"

3"

8

CAMPER SHELL

(MOUNTING PLATES WILL VARY DEPENDING

ON MAKE AND MODEL OF TRUCK)

#2 = Position the rack on the truck as far forward as possible, with Mounting Plate tongue over the front bulkhead of the

truck bed. Center the rack left to right on truck bed. Slide the front Mount Plates apart so that they are flush against

opposite sides of the truck bed. Measure the inside dimension of the Mount Plates just above the Support Bar, and the

outside diminsion of the ridges (if any) on the bottom of your shell. It may be necessary to notch this ridge to avoid

interference with the Mount Plates. Or, you may want to notch the ridge front and back so that the Mount Plates can be slid

in towards the center of the truck to minimize overhang.

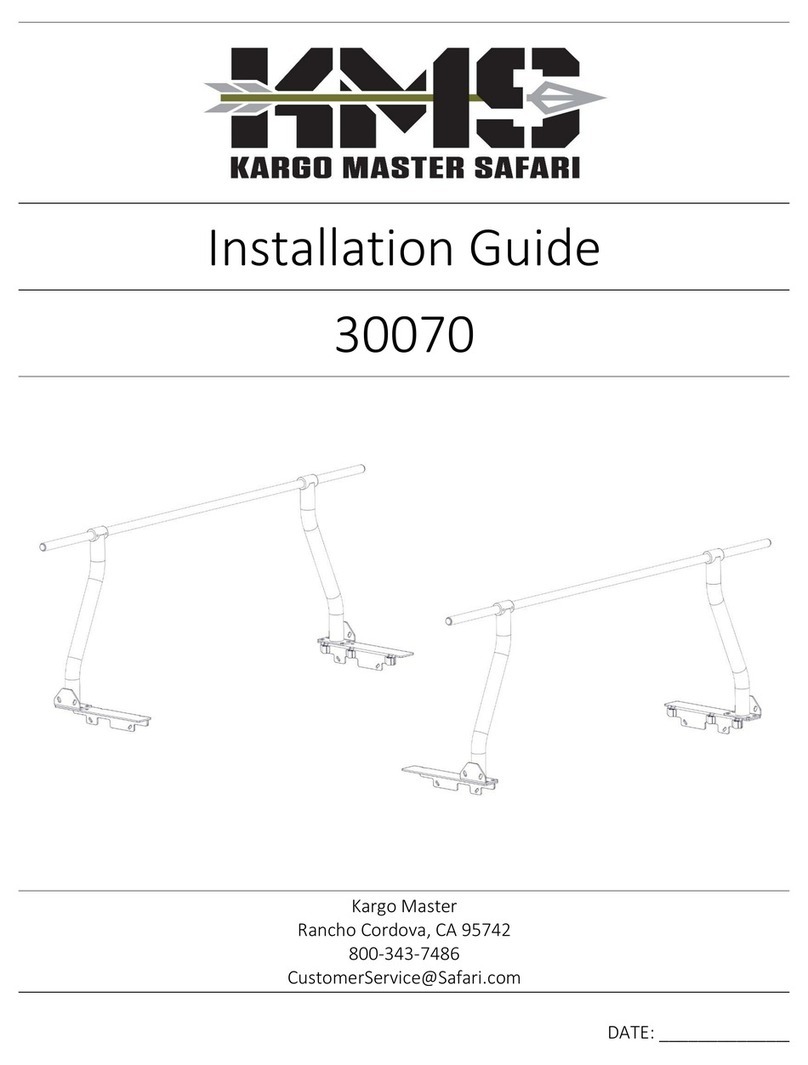

#4 = Remove Rack from the truck, and unbolt the Mounting Plates. Punch hole centers in the locations that you have

marked and drill 3/8" holes in the Mount Plates and the inner Support Arm.

#5 = Bolt the Support Arms together using bolt W , Flat washer U, and lock nut R.

#6 = Set the Mount Plates back on the truck, in exactly the same

location that they were before. Make certain that the Mount Plate is

square with the bed rail and dead horizontal. We recommend that you

clamp each foot plate in position before drilling through the truck's bed

rail. CHECK TWICE - DRILL ONCE!

#7 = Apply adhesive foam tape (NOT INCLUDED) to seal the

gaps between the footplates and camper shell along the bed

rail and bulk head. Attach the camper shell to the truck. Place

the rack on the Mount Plates and center. Adjust each rear leg

slightly side to side to ensure that the lock pins in the

removable rear bar slide in and out easily.

Tighten up ALL bolts and...

#1 = Remove your camper shell from truck. Note wheather or not there is

a ridge on the bottom of your shell.

#3 = With the Mount Plates in their final position, locate and mark two optimal bolt hole locations on the top of each Mount

Plate. The bolts should be located as far apart as possible, with clear access to the bolt and nut underneath the truck's bed

rail. If the inside of your truckbed has a double wall and it is not possible to locate a bolt on the Mounting Plate near the leg,

we recommend using our accessory STAKE POCKET "T" BOLTS to provide an additional attachment point. With the

Front Mount Plates in thier final location, mark the through bolt hole in the inner Support Arm.

STEP 8

KS_11_1.1