Contents

4/44

Contents

1 Important information ............................................................................................................. 5

1.1 Safety information .......................................................................................................... 5

1.2 Intended use .................................................................................................................. 7

1.3 About this manual .......................................................................................................... 7

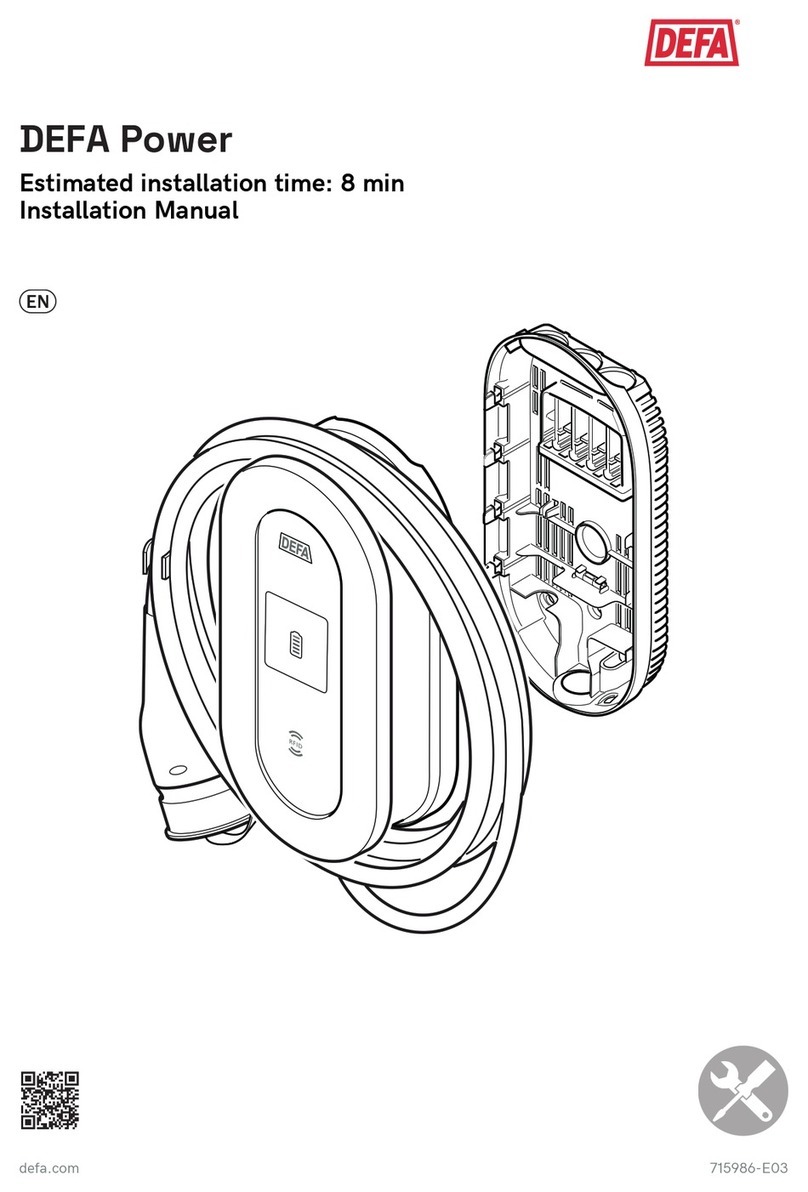

1.4 Product description ........................................................................................................ 8

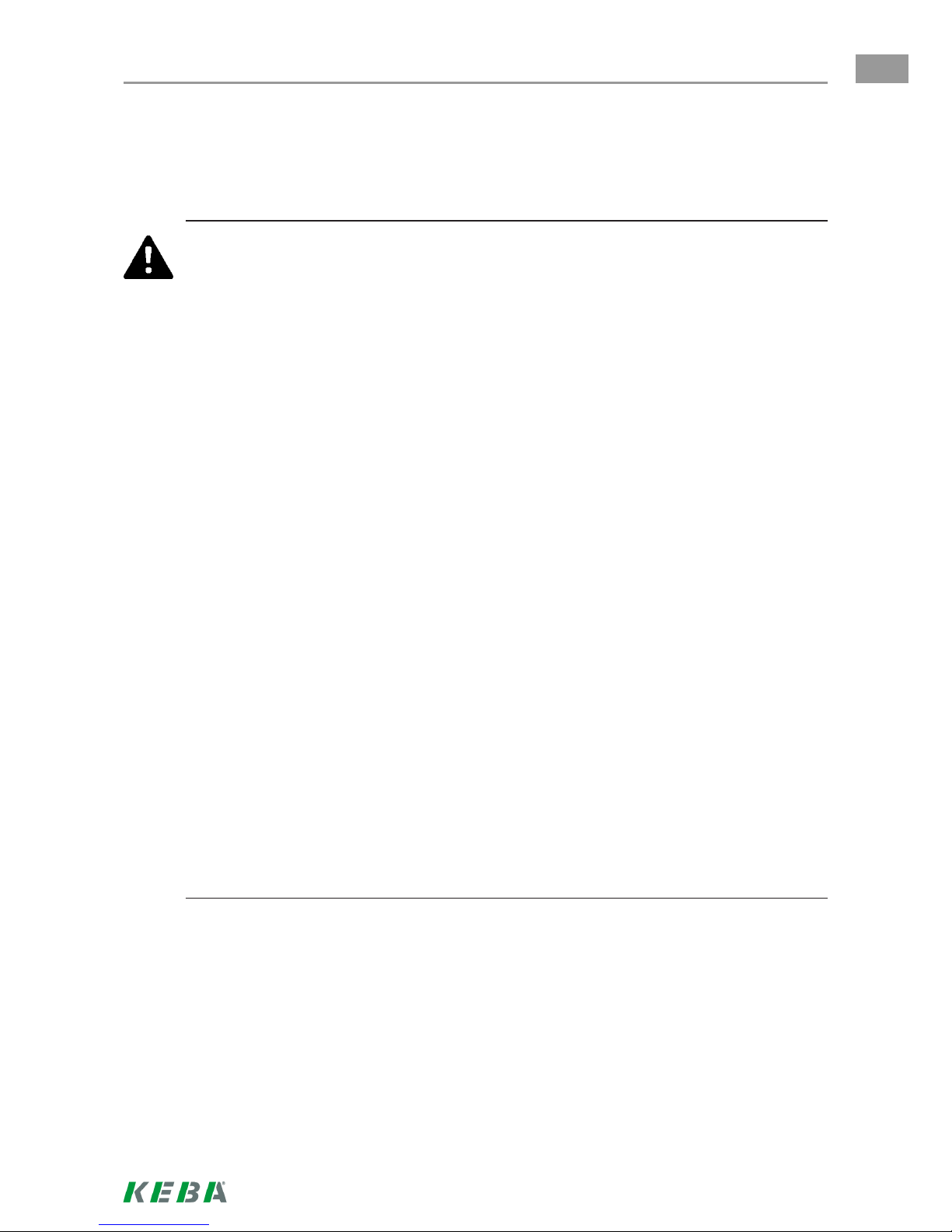

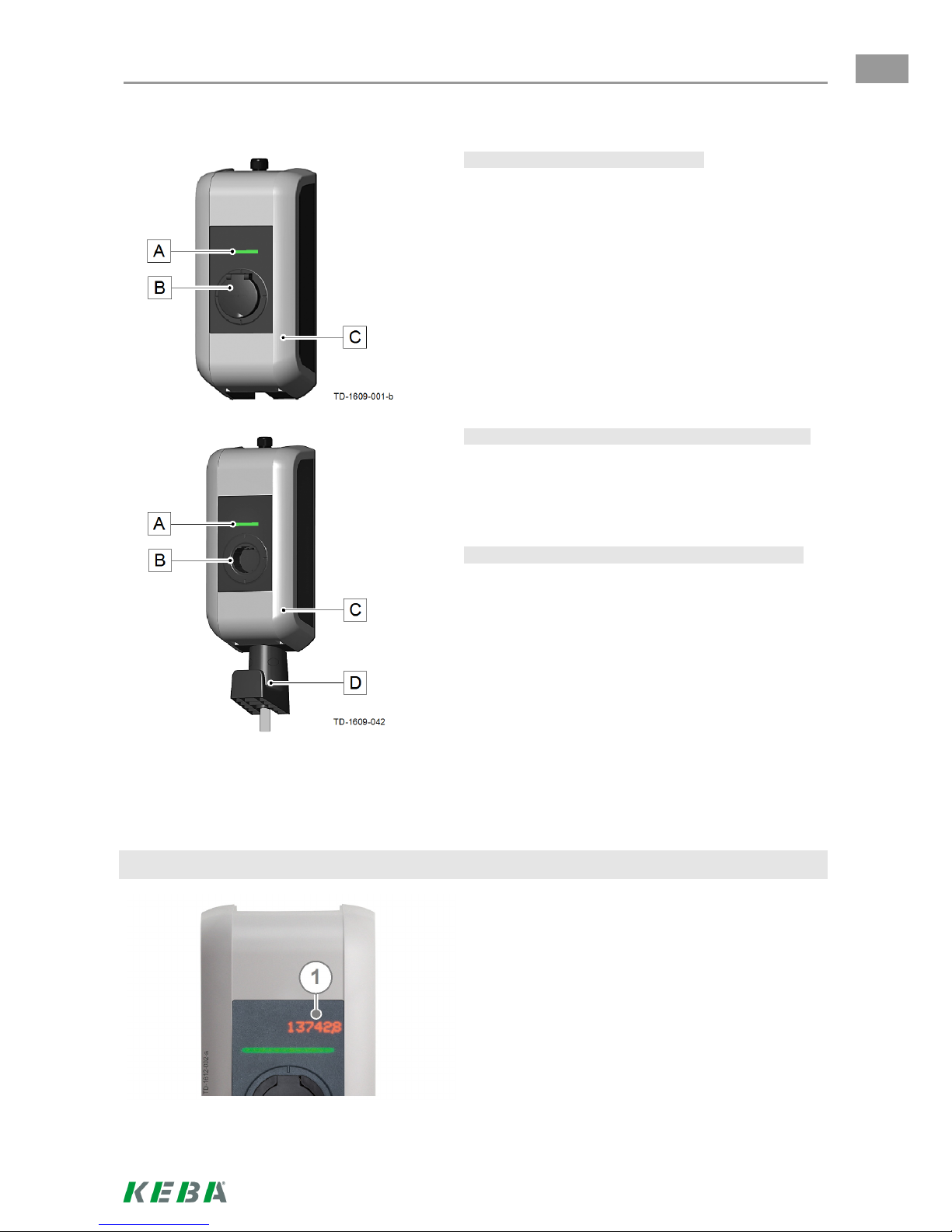

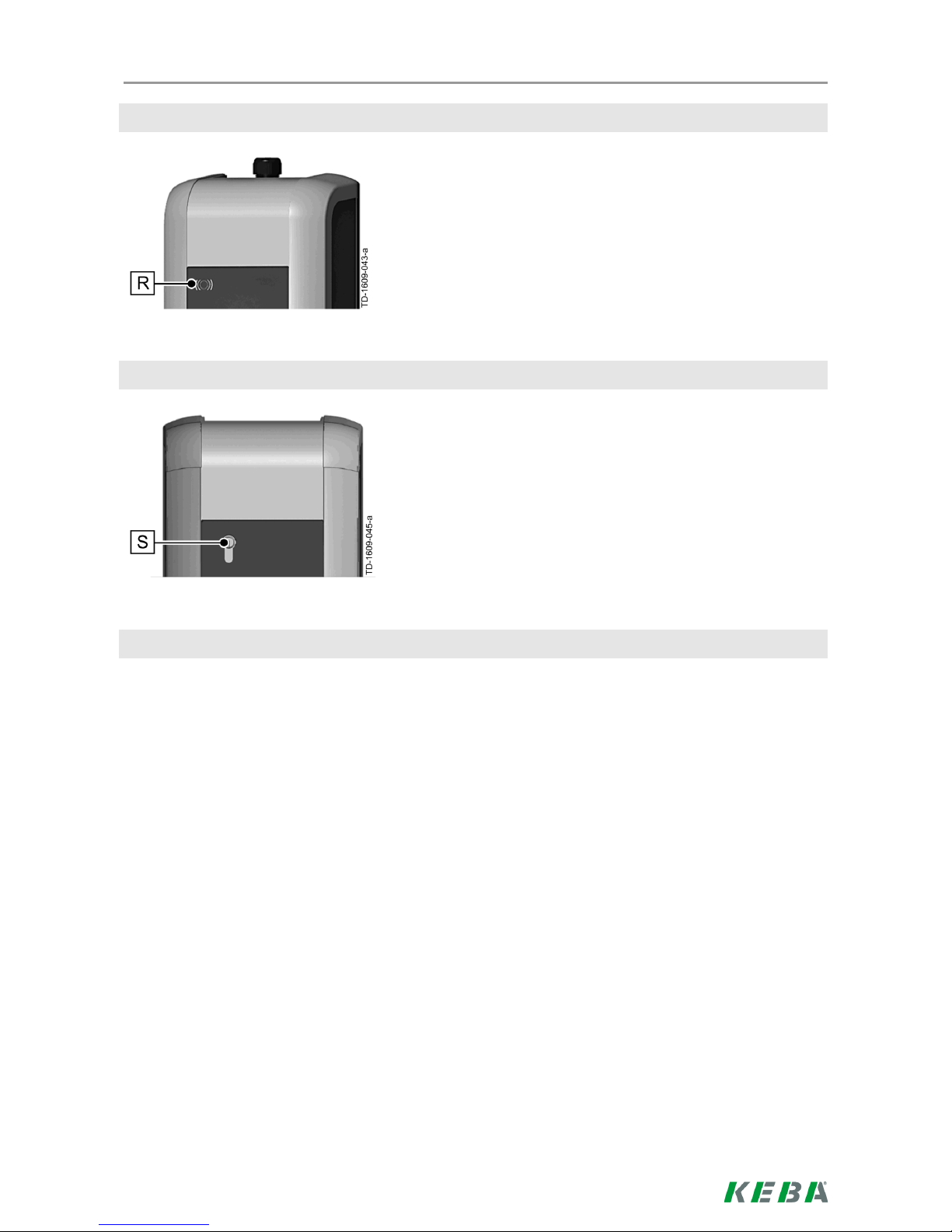

2 Variant overview...................................................................................................................... 9

2.1 Optional equipment........................................................................................................ 9

3 Installation guidelines........................................................................................................... 11

3.1 General criteria for the site selection ...........................................................................11

3.2 Specifications for the electrical connection .................................................................. 12

3.2.1 General ......................................................................................................... 12

3.2.2 Differing Z.E.-Ready / E.V. Ready requirements ......................................... 13

3.3 Space requirements..................................................................................................... 14

4 Installation ............................................................................................................................. 15

4.1 Installation requirements.............................................................................................. 16

4.2 Preparing the housing.................................................................................................. 17

4.2.1 Removing the housing cover ........................................................................ 17

4.2.2 Removing the connector panel cover ........................................................... 18

4.3 Preparing the cable insertion ....................................................................................... 18

4.3.1 Cable insertion from above - surface cable routing ...................................... 19

4.3.2 Cable insertion from behind - flush-mounted cable routing .......................... 19

4.4 Mounting the charging station...................................................................................... 20

4.5 Electrical connection .................................................................................................... 22

4.5.1 Connection overview with opened connector panel cover............................ 22

4.5.2 Connecting the power supply line................................................................. 23

4.5.3 Enable input [X1] (excluding e-series) .......................................................... 26

4.5.4 Switch contact output [X2] (excluding e-series)............................................ 27

4.5.5 Terminals [X1/X2] (excluding e-series)......................................................... 28

4.5.6 Ethernet1 connection [ETH] (optional).......................................................... 29

4.6 DIP switch settings....................................................................................................... 31

4.7 Commissioning ............................................................................................................ 34

4.7.1 Commissioning mode/self test...................................................................... 34

4.7.2 Safety checks ............................................................................................... 35

4.7.3 Firmware update........................................................................................... 35

4.7.4 Mounting the connector panel cover............................................................. 36

4.7.5 Mounting the housing cover.......................................................................... 37

5 Additional technical instructions......................................................................................... 38

5.1 Programming RFID cards (optional) ............................................................................ 38

5.2 Communication with the electric vehicle PLC->Ethernet (optional; P20 only) ............. 38

5.3 Replacing the fuse ....................................................................................................... 38

5.4 Dimensions .................................................................................................................. 39

5.5 Technical data.............................................................................................................. 40

5.6 CE Declaration of Conformity ......................................................................................42

Index ....................................................................................................................................... 43