Cannular Compact Canning Machine Instruction Manual

Page 4of 27 www.KegLand.com.au Last Updated 4/03/2021 2:06 PM

Your Cannular is calibrated and set up at the factory to seam KegLand 500mL B64 cans

(KL05449, KL18517 and KL15684), however, due to an extended transit time it may have

shifted out of specification during its journey. Before making any adjustments to the seamer

follow the following initial start-up instructions:

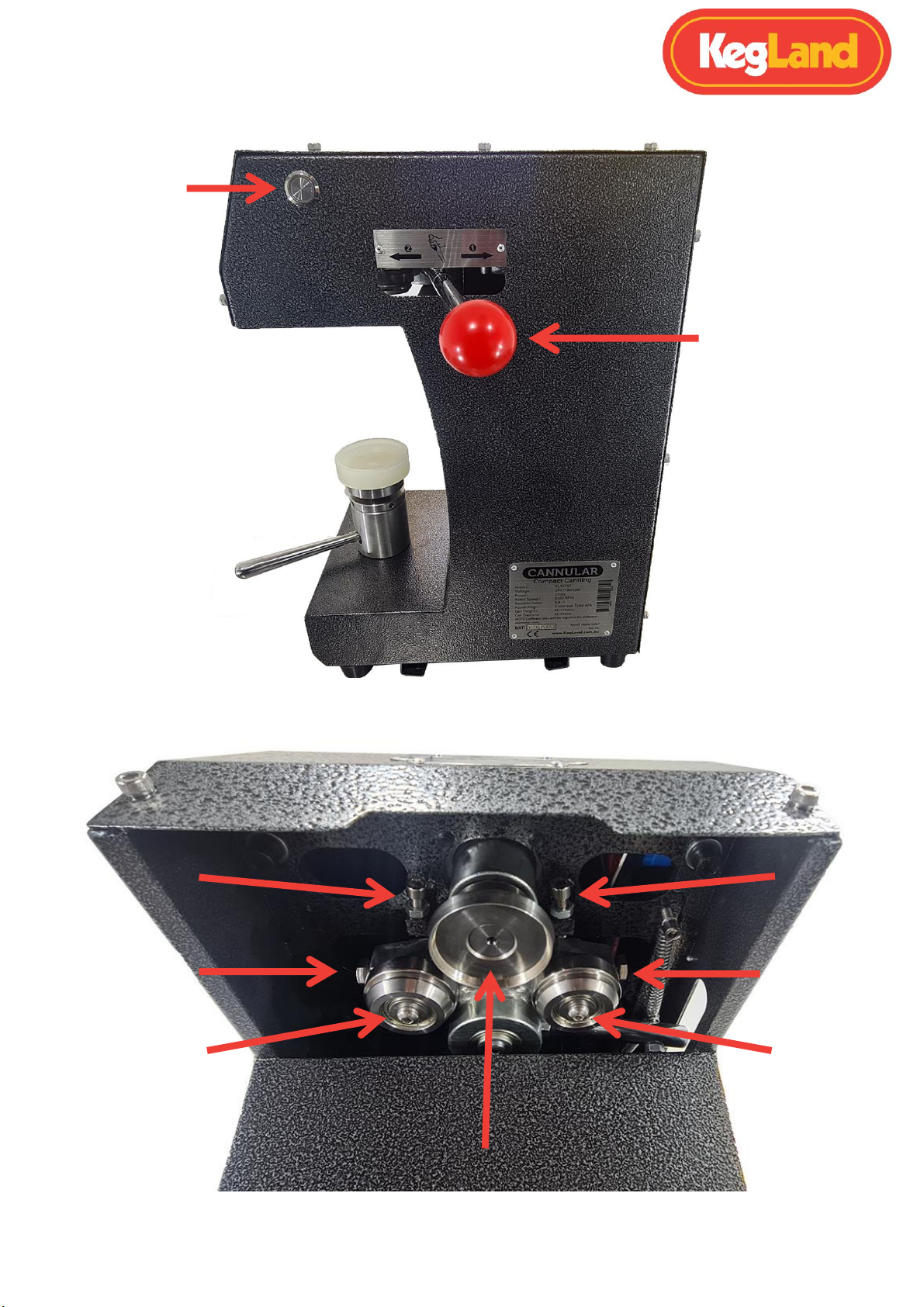

1. Remove the top of the Cannular to improve access to the chuck and rollers.

2. With the Cannular unplugged from the power supply, push and the lever forward

(operation 1 position). While holding the lever in this position manually rotate the 1st

operation roller and look/listen for any signs of the roller containing the chuck.

Repeat this for the 2nd operation roller by pulling and holding the lever back. If either

roller contacts the chuck then adjust the position of the rollers according to the

measurements on pages 14-18.

IMPORTANT: Under no circumstances allow the rollers to come into contact with the

chuck. As these are both made from hardened steel and both require high tolerances.

Both chuck and rolls can quickly get damaged if they are to come into contact. Prior to

seaming a can hold the lever in position one and turn the 1st operation roller with your

hand and make sure that the 1st operation roller never comes into contact with the chuck

at any point in time. Repeat this with the 2nd operation roller.

3. Once you have confirmed that the rollers do not contact the chuck, fill a can with

soda water or any other carbonated beverage, and place the lid on the full can.

4. Place the correct table spacer for your specific can onto the turntable, then plug the

Cannular into the power supply.

5. Raise the table and ensure the can and can lid are held firmly concentrically into the

chuck.

6. Press the power switch on the Cannular.

7. Push and hold the lever forward for 1 second and then pull and hold the lever back

for 1 second. Holding for too long in either direction can result in an incomplete or

damaged seam.

8. If it is determined that the seam leaks then calibrate the Cannular according to the

instructions on pages 14-27.