© www.kemper-group.com – 09.2023 / K410036900025-00 – 3 /56

Safety instructions

Power supply 230 V AC

Electrical power input DN 20: 3,3 A

DN 25: 5,5 A

Electrical power DN 20: 759 W

DN 25 1265 W

Power factor 0,97

Protection class IP 54

Medium Water

Ambient temp., max. 40°C

Ambient temp., min. 2°C

Inowing medium, temp. max. 35°C

Inowing medium, temp. min. 2°C

Flow pressure, max. DN 20/DN 25: 4,0 bar | 0,4 MPa

Flow pressure, min. DN20: 1,0 bar | 0,1 MPa

DN25: 1,5 bar | 0,15 MPa

Pressure stage PN 10

Outlet pump pressure DN 20: 4.3 bar | 0,43 MPa

DN 25: 5,9 bar | 0,59 MPa

DU value DN 20: 0,83 l/s

DN 25: 1,67 l/s

Sanitary and drinking water installation:

DIN EN 1717 / DIN 1988-100

DIN EN 806-5

EMC:

EN 61000-6-1

EN 61000-6-3

Low-voltage:

EN 60335-1

Machinery Regulation:

(EU) 2023/1230

Use the device

- only in sound condition

- as intended.

Note! A software update is recommended if the current version of

the rmware is not present.

Liability

No warranty or liability for:

- Non-compliance with the instructions.

- Incorrect installation and/or operation.

- Unauthorised modication of the product.

- Other incorrect operation.

Warning! Any water withdrawn must under no

circustances be used as drinking water – even in small

amounts!

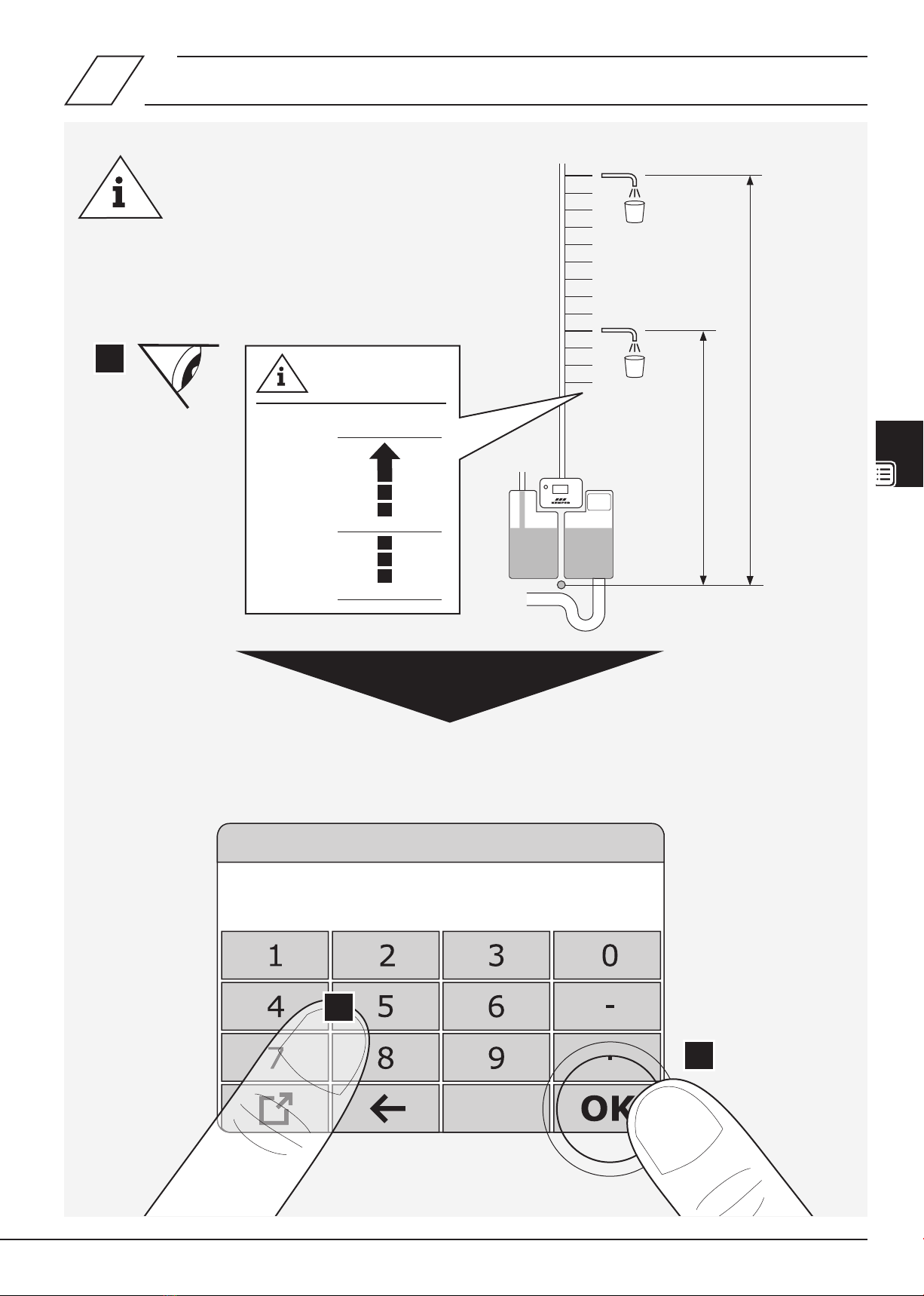

Note! The inlet valves and pump switch on automatically

for a short period of time if the device has not been used

for more than 48 hours.

Note! Only use suitable cleaning agents that do not foam

according to DVGW W 291 / W 319.

After cleaning the device, you must remove any cleaning

agent residues from the system completely!

Maintenance and repair

Warning! Only competent specialists with drinking water

installation qualications are permitted to carry out repair

or maintenance work.

Danger! Only specialists with electrical system

qualications are permitted to carry out electrical

installation, repair or maintenance work!

Danger! Before working on live components, be

sure to disconnect the system from the power supply.

Danger! Prior to any maintenance work on electrical

elements, disconnect the system from the mains. To do

this, always disconnect the mains plug.

Warning! Following the installation, addition of accessories or

maintenance, all feed pipes must be ushed according to DIN EN

806-5 and VDI/DVGW (Association of German Engineers/German

association for gas and water) 6023.

Warning! Priority must be given to the national and regional stan-

dards and provisions on sanitary installations, electrical installations

and accident prevention.

Note! Only remove the USB stick once data transmission is comple-

te, or the controller may be damaged during a rmware update.

Important notes for the device operating organisation

Important notes for the device operating organisation