KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

022720 228-1921 3

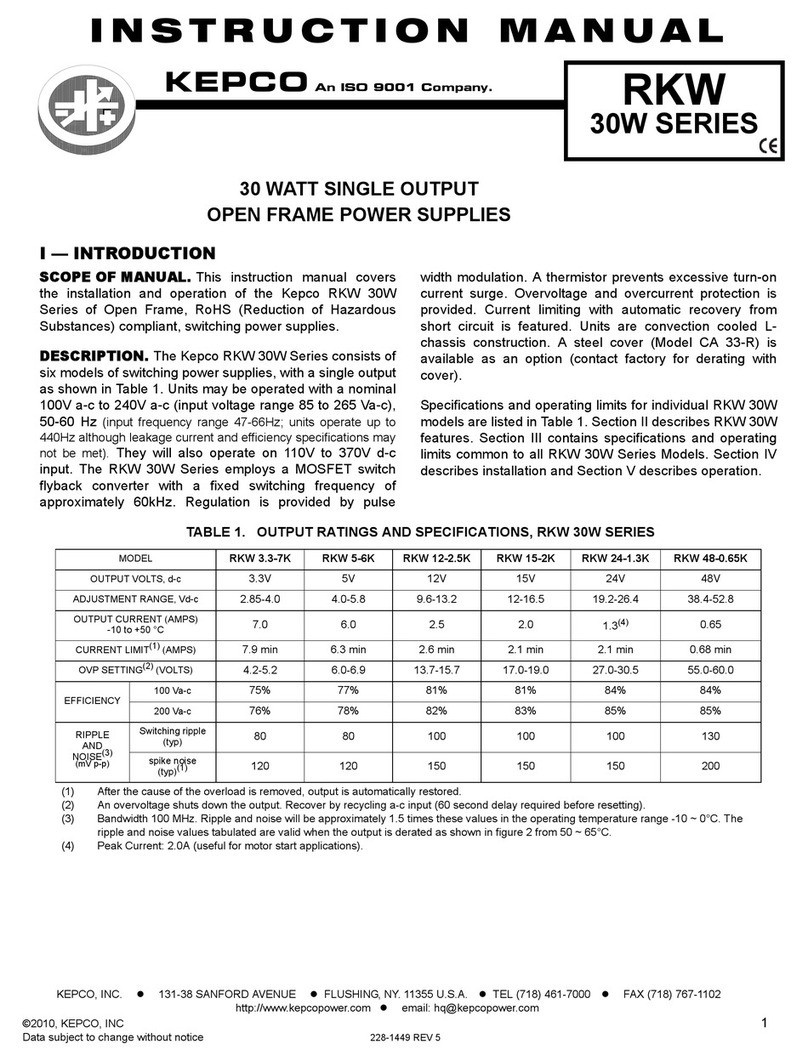

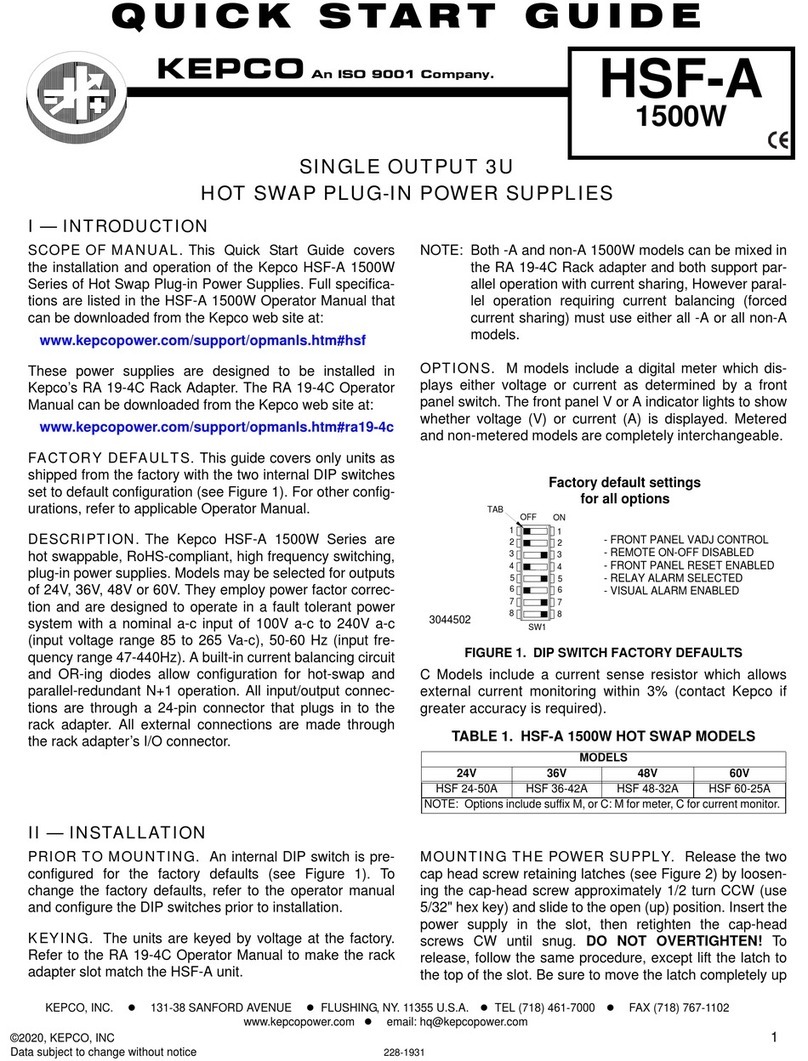

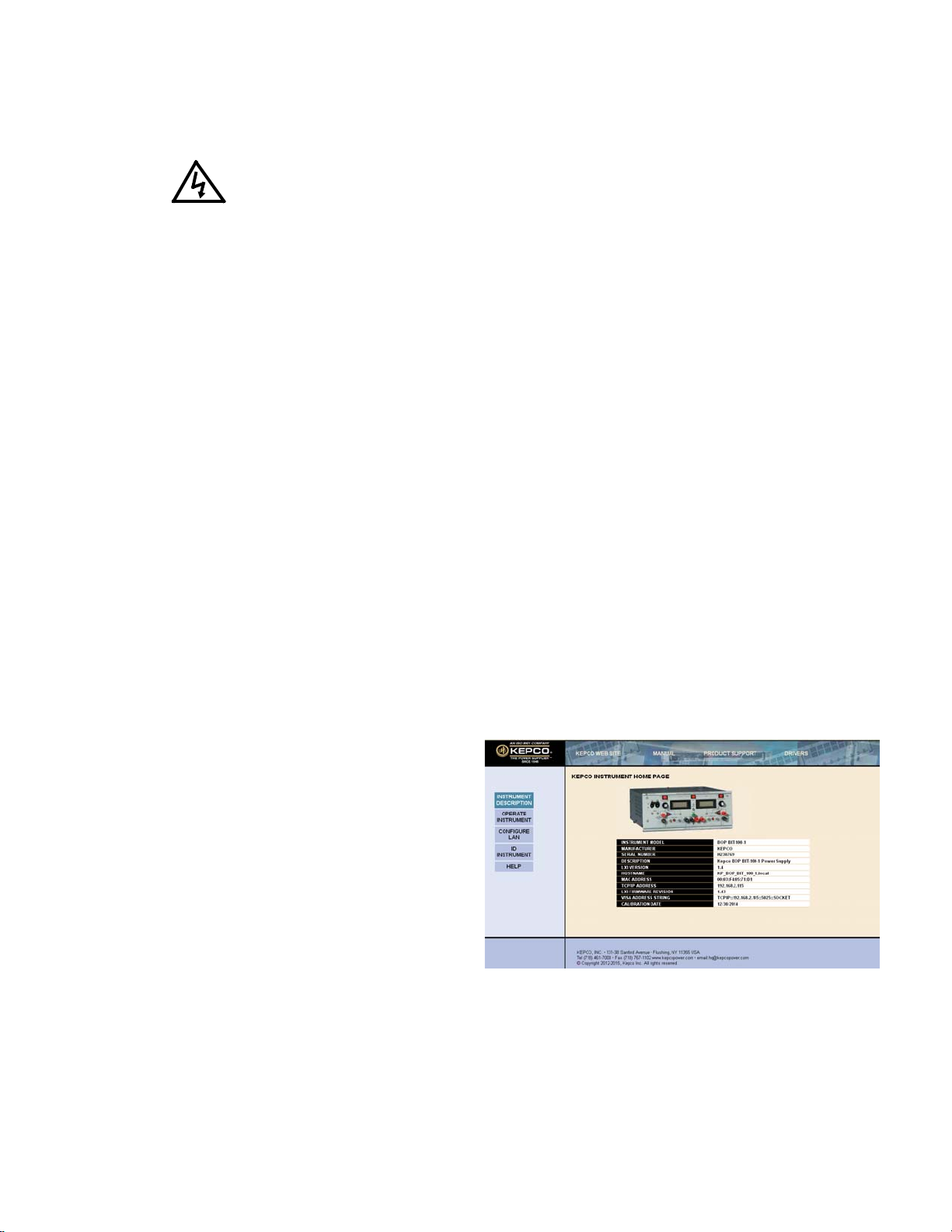

10.If necessary, click on the MODE button at the upper

right side of the Operate Instrument page until the indi-

cator above the MODE button reads VOLTAGE.

11.Set the unit to output +8.1V by entering +8.1 in the

VOLTAGE field, then click SET. Verify the output of the

BOP changes and the voltage indication is +8.1V on

both the web page and the BOP front panel.

FIGURE 3. OPERATE INSTRUMENT PAGE

12.Repeat steps 1 through 11 for channel 2. At step 2 set

selector switch to CHANNEL 2

13.Set the a-c POWER switch for channels 1 and 2 to OFF.

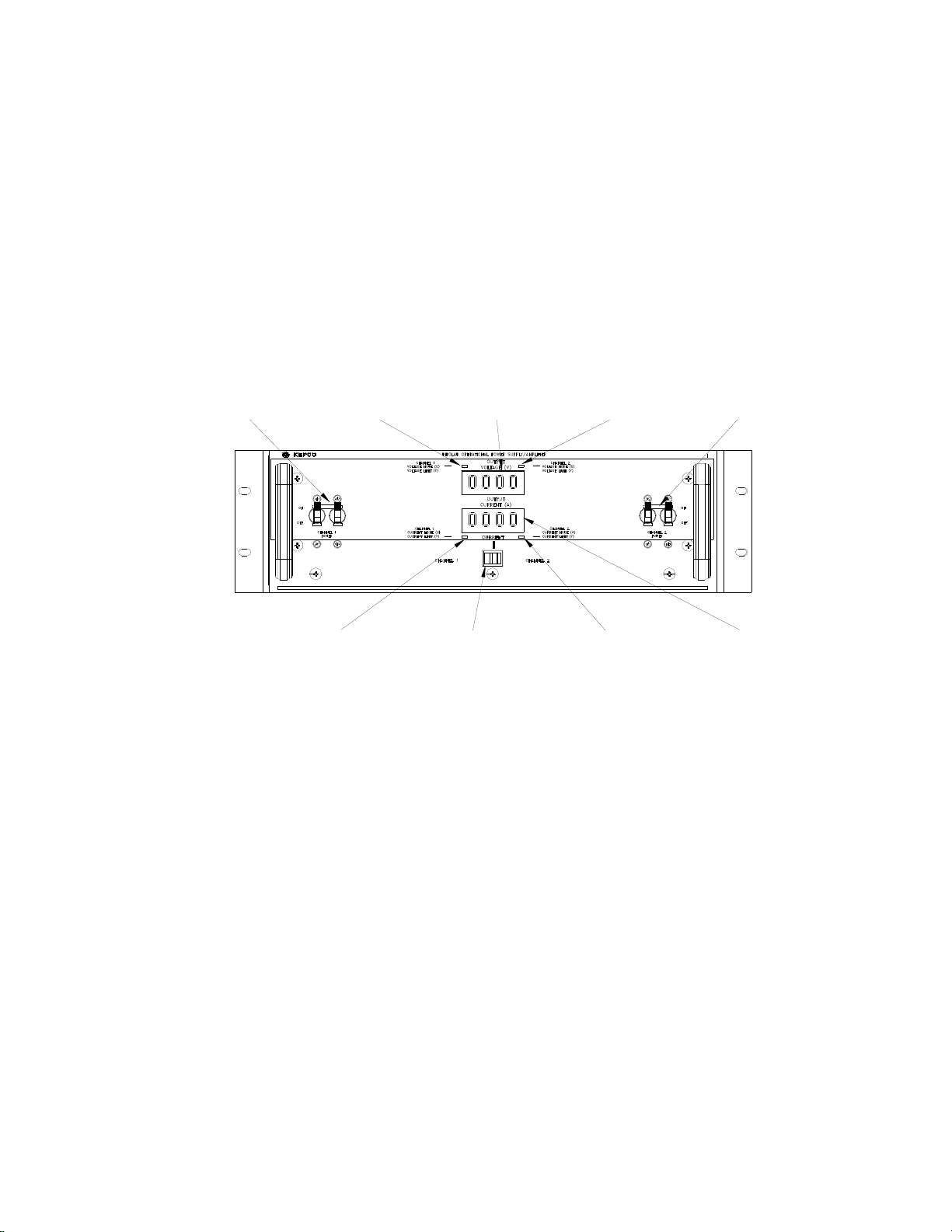

3.3. INSTALLING THE POWER SUPPLY. These

models are shipped with fixed angle brackets and chassis

slide support bars installed and are ready for mounting in a

19-inch rack.

3.4. CONNECTIONS. Connections to the load are

made using the rear panel terminations.

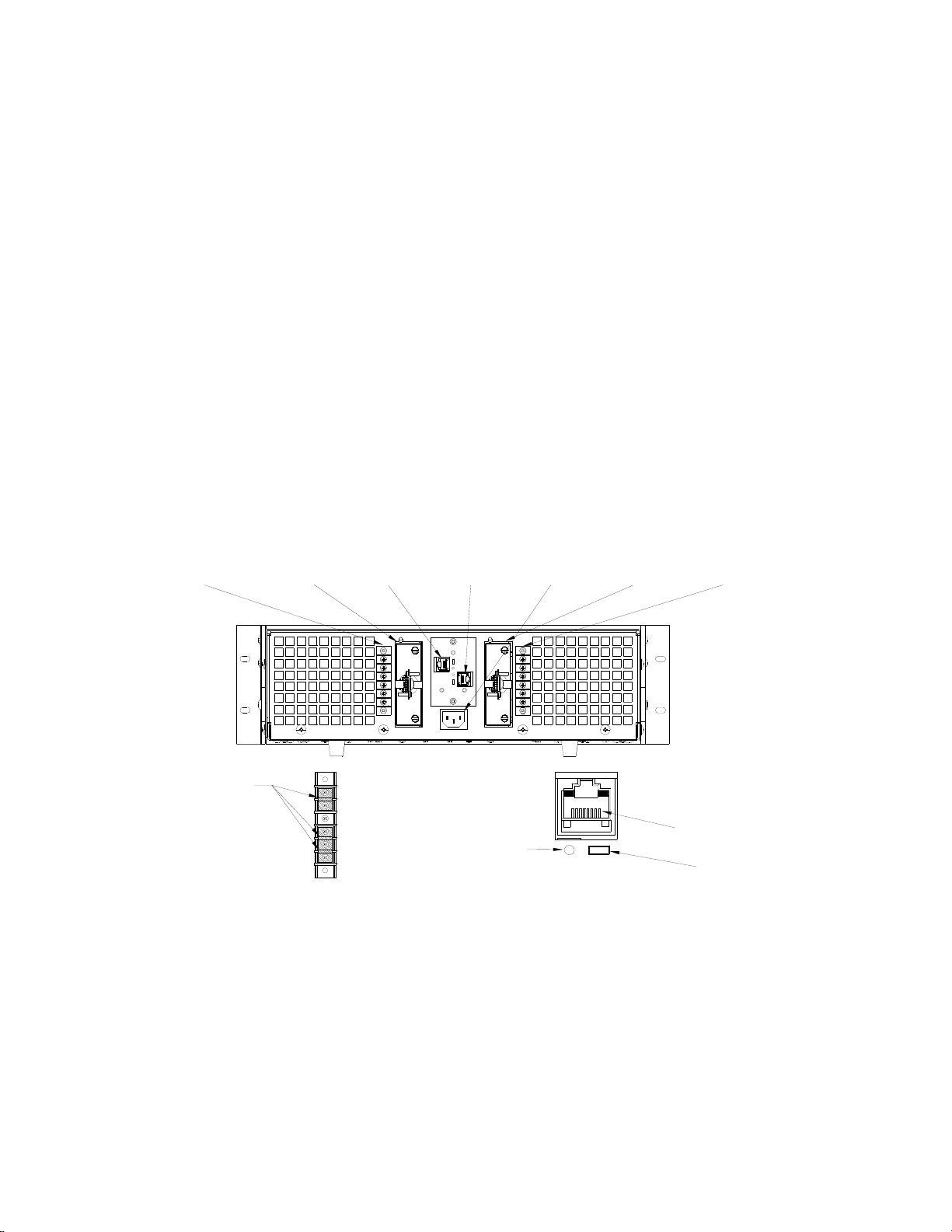

LOAD CONNECTIONS. Connect the load between OUT

(output) and COM (common) terminals at the rear panel.

Sense connections are required; otherwise the unit will

not operate properly.

LOCAL SENSE CONNECTIONS. For local sensing the

OUT and COM terminals are connected to the adjacent S

(sense) terminals. The unit is shipped with local sensing

links in place at the rear panel.

REMOTE SENSE CONNECTIONS. Remote sensing (con-

necting the corresponding S terminals to the OUT and

COM terminations at the load instead of at the BOP) can

compensate for load wire losses up to 0.5V per wire (0.25V

per wire on models with rated output less than 20V).

Remote sensing is recommended for minimum load effect

in voltage mode for a remote load. Use twisted pairs: #22

AWG for output sense lines and wires rated for the nominal

output current of the power supply for power leads. See full

Operator Manual (see PAR. 1.1) for remote sensing

requirements.

GROUNDING NETWORK. The unit is shipped with a link

installed between GND NET and GND terminals at the rear

panel to enable the Grounding Network. This network

reduces noise/ripple that may be present at the output

when the output is not grounded.

INPUT A-C CONNECTIONS. Install the line cord (sup-

plied) at the rear panel and connect to 115V a-c, 60Hz

(105V to 125V a-c, 47 to 63Hz) mains. Refer to the full

Operator Manual (see PAR. 1.1). For operation at 104V

a-c, 208V a-c or 230V a-c refer to the full Operator Manual

(see PAR 1.1).

A-C GROUND. The 3-wire line cord with 3-prong safety

plug (supplied), in combination with a properly grounded

a-c power outlet, automatically grounds the BOP 2X-DE

case. If an adapter for a non-grounded outlet is used, the

case must be grounded separately using the GND terminal

at the rear panel terminal block. The ground wire must be

rated for at least the BOP input current (as noted on name-

plate at rear of unit).

D-C SIGNAL GROUND. Specified ripple and noise figures

for BOP power supplies are valid only with the COM side of

the output load circuit returned to a ground point. The BOP

circuits, including output and programming terminals, have

no d-c connection to the chassis.

Each output terminal of each BOP channel can be “floated”

up to 250 volts (d-c or peak) off chassis ground. The com-

mon mode current (leakage from output to ground) is less

than 50 A (rms) or 5 mA (p-p) at 115V a-c, 60 Hz power

input. To avoid common mode current from affecting the

BOP output, the system (including the programming

device, if used, load, and BOP) can have a single connec-

tion to ground (earth ground). The d-c ground wire must be

rated for the nominal output current of the BOP (e.g., for

BOP 20-10D, use rating of 10A).

Multiple signal grounds in the system may cause “ground-

loop” and instability problems, since noise signals develop

across the impedances between the multiple ground

points. The exact physical location of the “best” single

ground point must be carefully selected for minimum ripple/

noise output and to avoid the possibility of output current

flowing through the return path of an external programming

signal.

REAR PROGRAMMING CONNECTOR, PC 15. Control of

each channel is via the associated rear panel programming

connector. (See Figures 4, 6, and 8). Table 1 lists the func-

tions of each terminal. For more details, refer to the BOP

2X-DE Operator Manual (see PAR. 1.1).