3

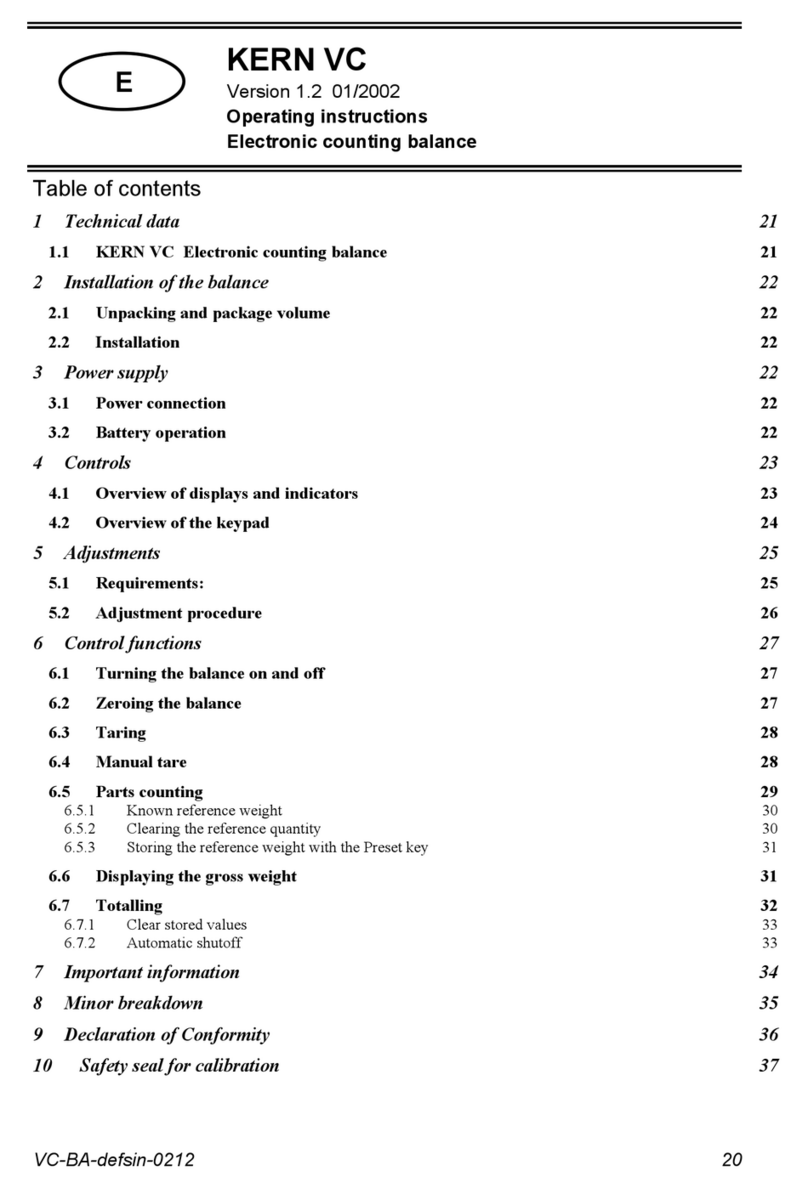

Contents

1 Putting into service ....................................................................................................................... 4

1.1 Unpacking and checking contents .................................................................................................. 4

1. Safety and environmental protection ................................................................................................ 4

1.3 Positioning and leveling the scale ................................................................................................... 5

1.4 Connecting to power supply ............................................................................................................ 6

1.5 Battery operation ............................................................................................................................. 6

1.6 Monitoring the test substances ........................................................................................................ 7

1.7 Verification ....................................................................................................................................... 7

2 Weighing ....................................................................................................................................... 8

.1 Switching on and off and zeroing .................................................................................................... 8

. Simple weighing .............................................................................................................................. 8

.3 Weighing with tare ........................................................................................................................... 8

.4 Recording weighing results .............................................................................................................. 9

.5 Special functions (master mode) ..................................................................................................... 9

3 Master ode .............................................................................................................................. 10

3.1 Overview and operation ................................................................................................................ 10

3. Adjustment (CAL) ........................................................................................................................ 10

3.3 Scale calibration (adjustment) ...................................................................................................... 11

3.4 Scale settings ............................................................................................................................... 14

3.5 Interface configuration .................................................................................................................. 15

3.6 Printing master mode settings ...................................................................................................... 17

3.7 Saving settings and exiting master mode ..................................................................................... 17

3.8 Making a typical setting in master mode ......................................................................................17

4 Other i portant infor ation ...................................................................................................... 18

4.1 Error messages ............................................................................................................................ 18

4. Cleaning instructions .................................................................................................................... 19

4.3 Declaration of conformity ............................................................................................................ 0

4.4 GEO-value table ...........................................................................................................................

4.5 Technical data .............................................................................................................................. 3

4.6 Interface commands .................................................................................................................... 5