4

1. Measuring Principles and Features

■ Measuringprinciple

■ Features

● Thecalibrationcurvememoryfunctionisintegrated.

Up to 50 types can be calibrated and stored as an application for each probe. Thanks

to this function, the measurement can be performed without troublesome calibration

from the second time at the same measurement. A memorized application will not be

erased even if the power is switched off.

● Satisfactorilydiversiedfunctionsareprovidedasacoatingthicknessgauge.

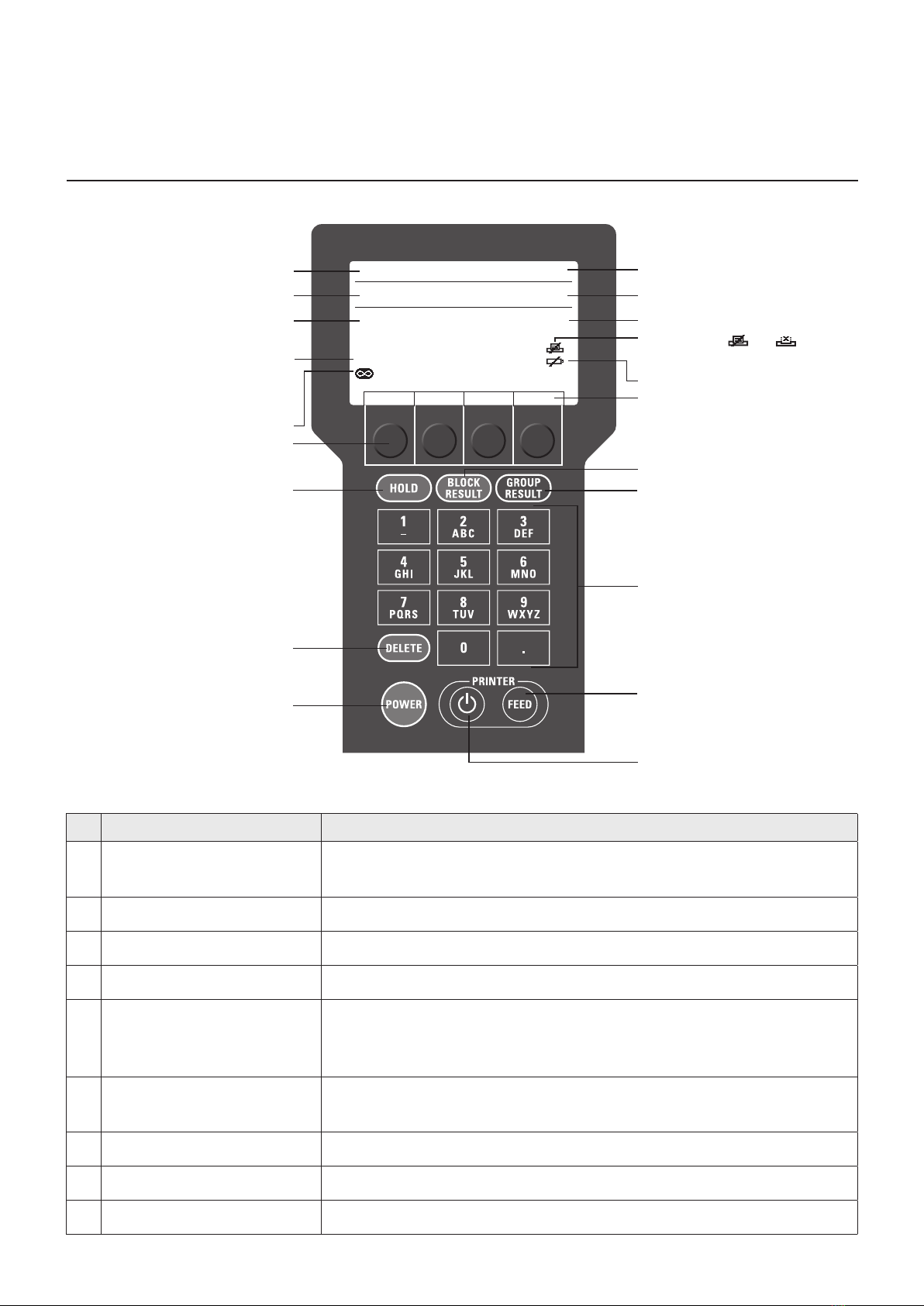

Various settings such as auto power-off function, backlight setting, upper/lower limit

setting function, and statistics function are available.

● Datacanbeoutputtedtotheprinter.

Measured values, statistical calculation results, and more can be printed with the built-

in printer.

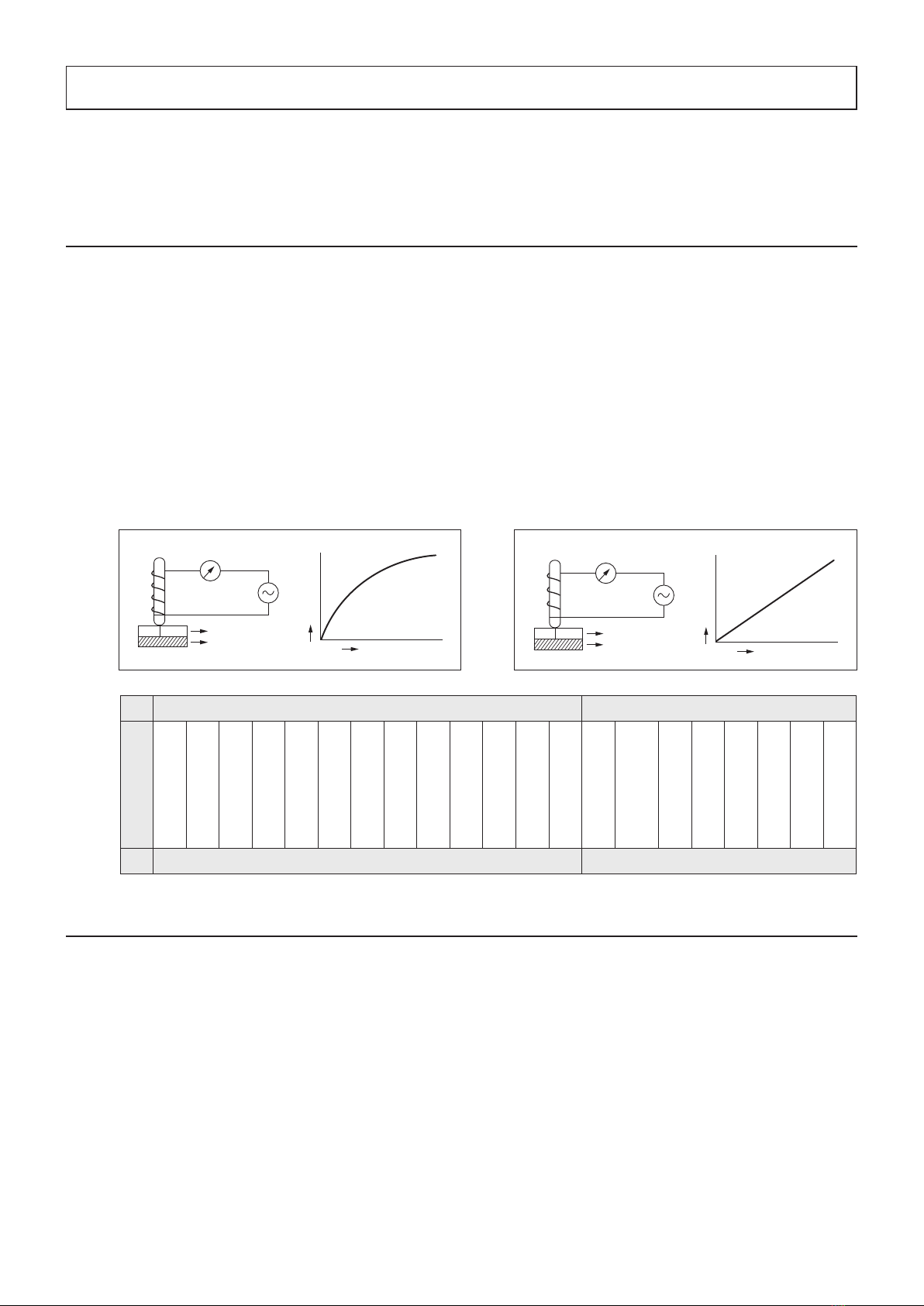

Electromagnetic type (Fe probe) Eddy current type (NFe probe)

Coating to be measured

Paint

Plastic

Lacquer

Resin

Rubber

Enamel

Lining

Zinc

Chrome

Tin

Copper

Aluminum

Other

Paint

(Anodic oxide coating)

Alumite

Rubber

Plastic

Enamel

Lacquer

Resin

Other

Substrate

Iron/steel Aluminum, Copper, Brass, etc.

● Electromagnetictype(Feprobe)

Measurement of non-magnetic coatings on

magnetic metals

If an electromagnetic coil through which a constant

low-frequency current flows is brought into the

proximity of iron (magnetic metal), the number of

magnetic ux lines through the coil varies with the

approaching distance, which causes the variation of

voltage between the ends of the coil. This change

in voltage is detected by the current value and is

calculated in terms of coating thickness.

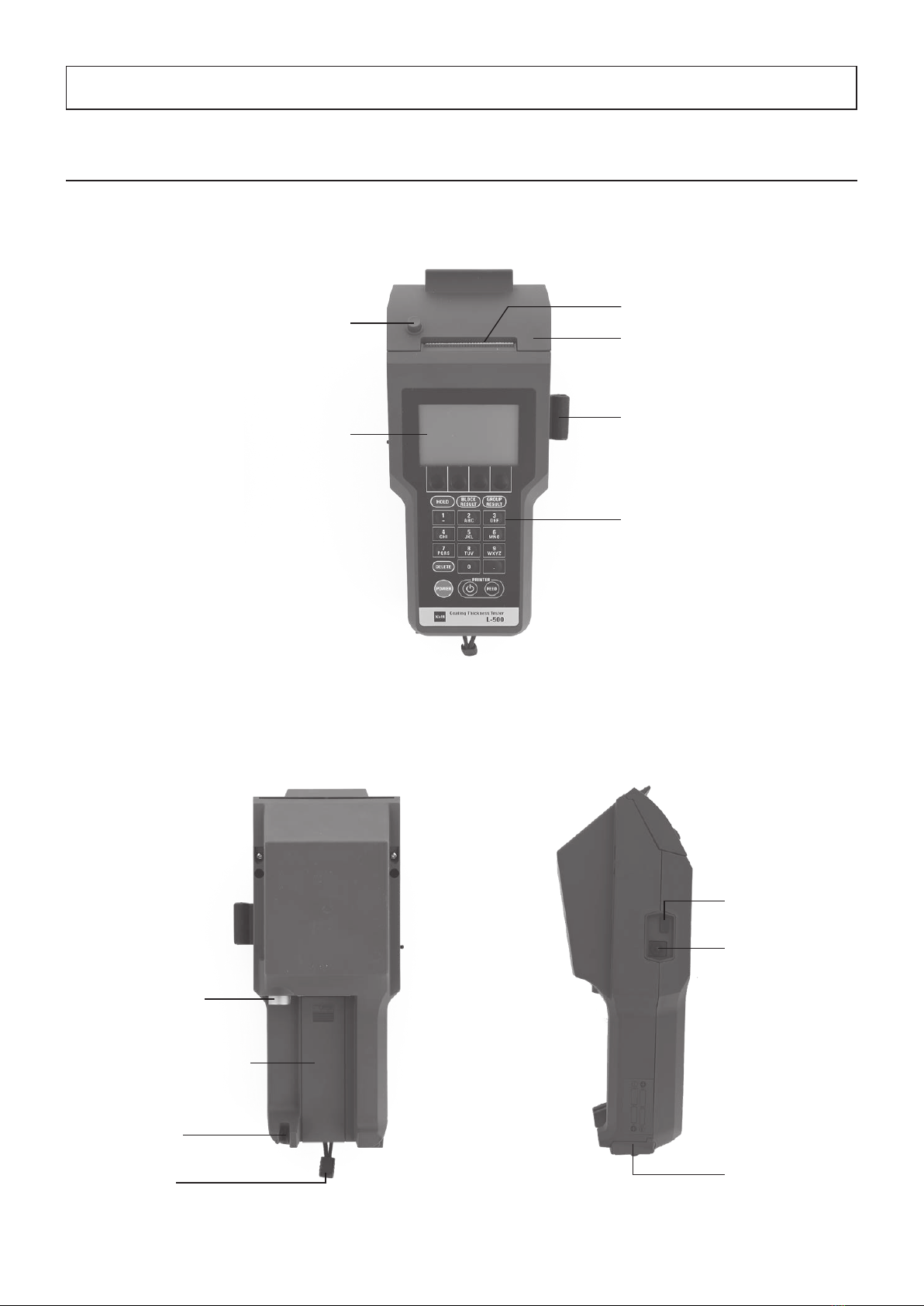

The Coating Thickness Tester L-500 is a coating thickness gauge that can measure in both

electromagnetic type and eddy current type depending on the probe to be connected.

Non-magnetic coating

D

Thickness D

lron/steel

Electromagnetic coil

i

Low-frequency power supply

i

Current change

Insulating coating

D

Thickness D

Non-ferrous metal

Induction coil

i

High-frequency power supply

i

Current change

● Eddycurrenttype(NFeprobe)

Measurement of insulating coating on non-magnetic

metals

If an induction coil through which a constant high-

frequency current ows is brought into the proximity

of a metal, eddy currents are generated on the

surface of the metal. Then these eddy currents

uctuate according to the distance between the coil

and the metal surface and thus changes the voltage

on each end of the coil. This change in voltage is

detected by the current value and is calculated in

terms of coating thickness.