5ASP-35

Table of Contents

Introduction��������������������������������������������������������������������������������� 1

Accessories �������������������������������������������������������������������������������������������������������1

This Booklet �����������������������������������������������������������������������������������������������������1

Introduction��������������������������������������������������������������������������������� 1

ManualConventions������������������������������������������������������������������� 2

SafetyRules���������������������������������������������������������������������������������� 3

ControlsandFeatures����������������������������������������������������������������� 5

Winch ���������������������������������������������������������������������������������������������������������������5

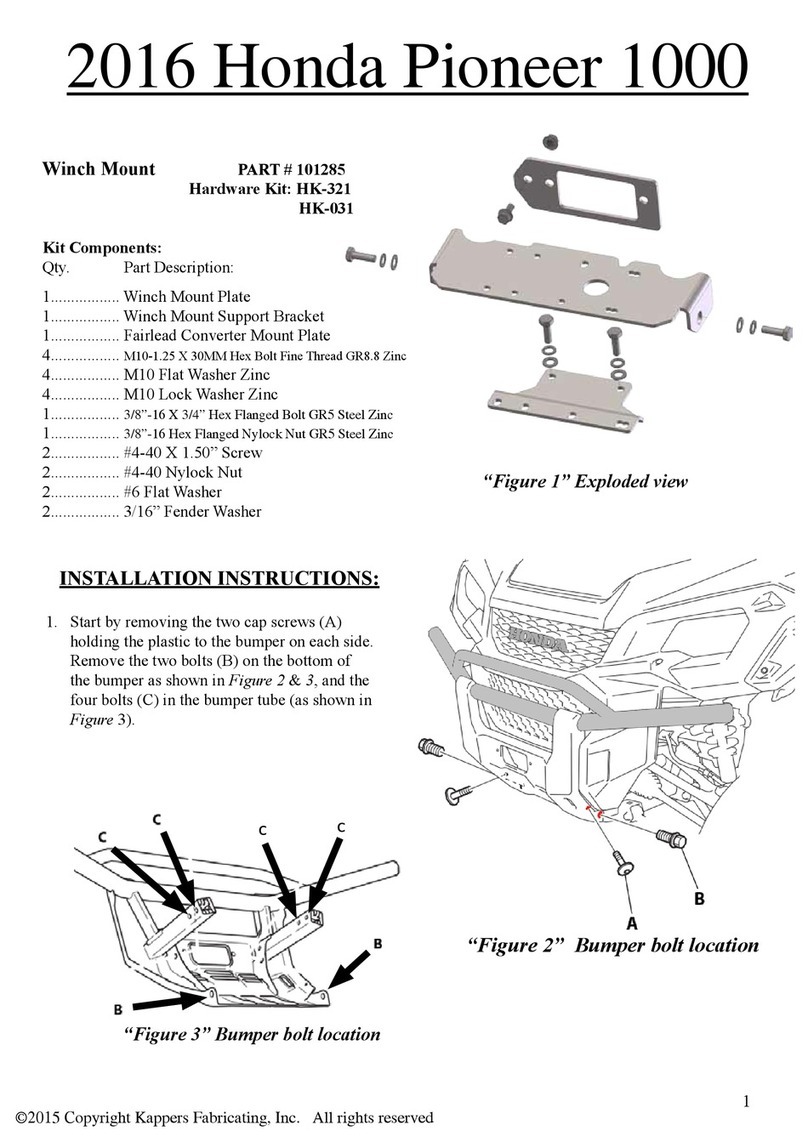

Installation������������������������������������������������������������������������������������ 6

Step 1-ATV Install Preparation ������������������������������������������������������������������������6

Step 2-Winch Assembly Preparation ����������������������������������������������������������������7

Step 3-Install Winch Assembly �����������������������������������������������������������������������8

Step 4-Handlebar Remote Install ����������������������������������������������������������������������9

Step 5-Reinstall ������������������������������������������������������������������������������������������������9

Operation������������������������������������������������������������������������������������ 10

General Tips for Safe Operation ���������������������������������������������������������������������10

Self Recovery �������������������������������������������������������������������������������������������������10

Winching Techniques ������������������������������������������������������������������������������������11

Maintenance������������������������������������������������������������������������������� 12

Motor ��������������������������������������������������������������������������������������������������������������12

Lubrication �����������������������������������������������������������������������������������������������������12

Cable Assembly Replacement ������������������������������������������������������������������������12

ASP-35Specifications��������������������������������������������������������������� 13

Performance Specifications ����������������������������������������������������������������������������13

Model Winch Diagram �����������������������������������������������������������������������������������14

Winch Parts List ���������������������������������������������������������������������������������������������15

Troubleshooting������������������������������������������������������������������������� 16

PlowingAlert������������������������������������������������������������������������������ 16

Warranty������������������������������������������������������������������������������������ 17

Warranty Qualifications ���������������������������������������������������������������������������������17

Repair/Replacement Warranty �����������������������������������������������������������������������17

Do not return the unit to the place of purchase ����������������������������������������������17

Warranty Exclusions ��������������������������������������������������������������������������������������17

Normal Wear �����������������������������������������������������������������������������������������������17

Installation, Use and Maintenance �����������������������������������������������������������������17

Other Exclusions ��������������������������������������������������������������������������������������������17

Limits of Implied Warranty and Consequential Damage �������������������������������17

Contact Information ����������������������������������������������������������������������������������������18

Address �����������������������������������������������������������������������������������������������������������18

Corporate: �������������������������������������������������������������������������������������������������������18

Customer Service ��������������������������������������������������������������������������������������������18

Technical Service �������������������������������������������������������������������������������������������18

Agreement ������������������������������������������������������������������������������������������������������18

SyntheticCable������������������������������������������������������������������������� 19