Installation

6 SE45w

Installation

This KFI 4,500 lb winch is designed with a

bolt pattern that is standard in this class of

winch. Many winch mounting kits are

available that utilize this bolt pattern for the

most popular ATV’s and UTV’s. You can find

most of the ATV/UTV winch mounts on our

Website www.kfiproducts.com

Step 1-Mount the Winch

WARNING

Before you start to install this winch, disconnect

the vehicle ground and positive leads from the

battery.

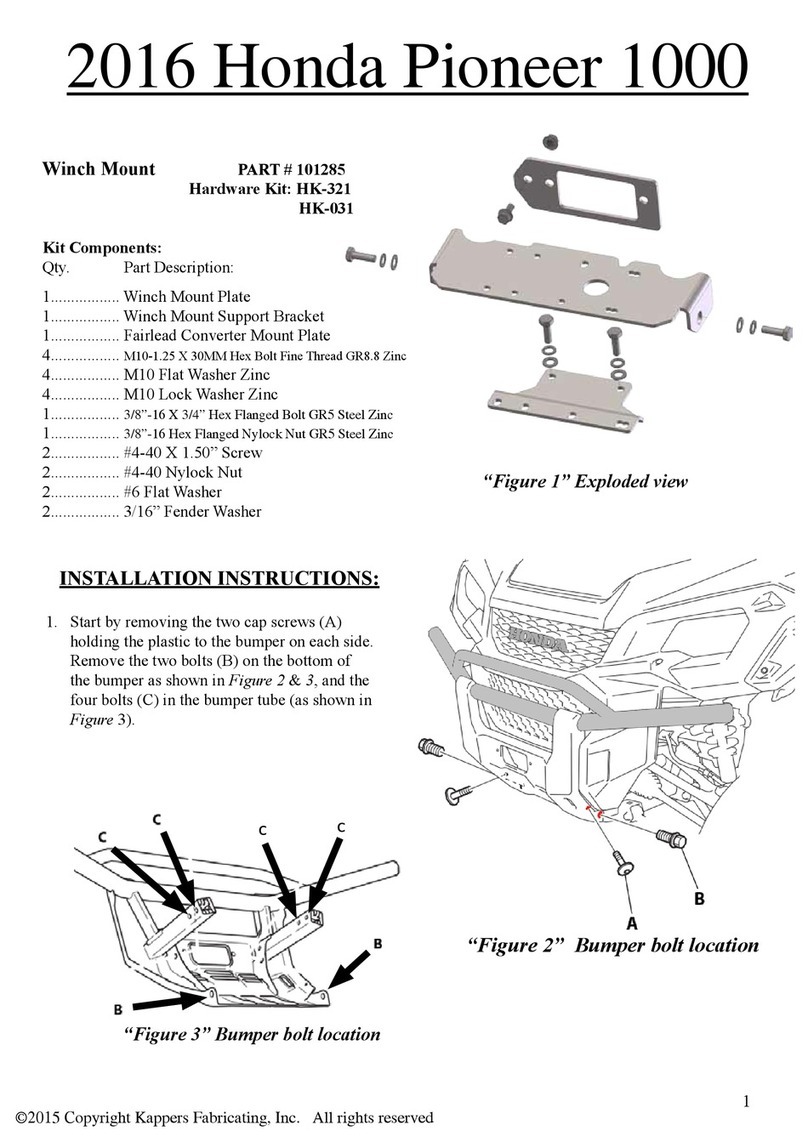

1. Install the winch and fairlead with the

supplied hardware per the instructions

provided with the model specific

mounting kit or prepare a flat, secure

mounting location for the winch.

NOTE

If you choose not to use a model specific mounting kit,

you will need to drill holes in the structural support of

the vehicle. Be certain that your structural support will

stand up to the pulling forces of this winch.

CAUTION

Mounting bolts must be SAE grade 5 or better

and torque to 17 ft. lbs.

2. Attach the winch using the M8 x 25 or

30 bolts and washers through the

fairlead bracket or model specific mount

and then into the winch.

3. Disengage the clutch by rotating the

clutch cap to the “FREESPOOL”

position. Release the wire rope and pull

through the roller fairlead.

4. Attach the clevis hook and hand strap to

the cable.

Step 2-Mount the Contactor

1. Find a location for the contactor. If the

Model specific mounting kit does not

indicate a recommended contactor

location, then it is recommended that

the contactor be mounted close to the

battery in a clean dry location. Make

sure the location you chose allows

sufficient clearance from all metal

components. Drill mounting holes if

required. Once location is found do not

install until all wiring is completed.

Step 3-Mount the Mini-Rocker

Switch

1. The switch is usually installed on the left

handlebar on ATV’s. If you are

installing on a UTV or SxS you can use

the supplied Bracket and hardware as

shown above. This bracket can be

placed in any location that is convenient

for you.

2. If mounting to the handle bars of an

ATV use a piece of electrical tape around

the handlebar to help prevent rotation of

the mount on the handlebar. Do NOT

tighten over any hoses or cables.

3. Once your switch is mounted you can

route the wires back to where your

contactor is located.

4. Splice the end of the red wire to an

ignition (keyed) controlled power source

using the supplied wire splice. You may

need to use a test light to locate a

suitable wire. The wire should only have

power when the key is in the ON

position.

5. If mounting to the handle bars of an

ATV make sure the handlebars have full

range of motion and then secure the

switch’s cable with the supplied cable

ties.

Not to scale. Do NOT use as a template