3

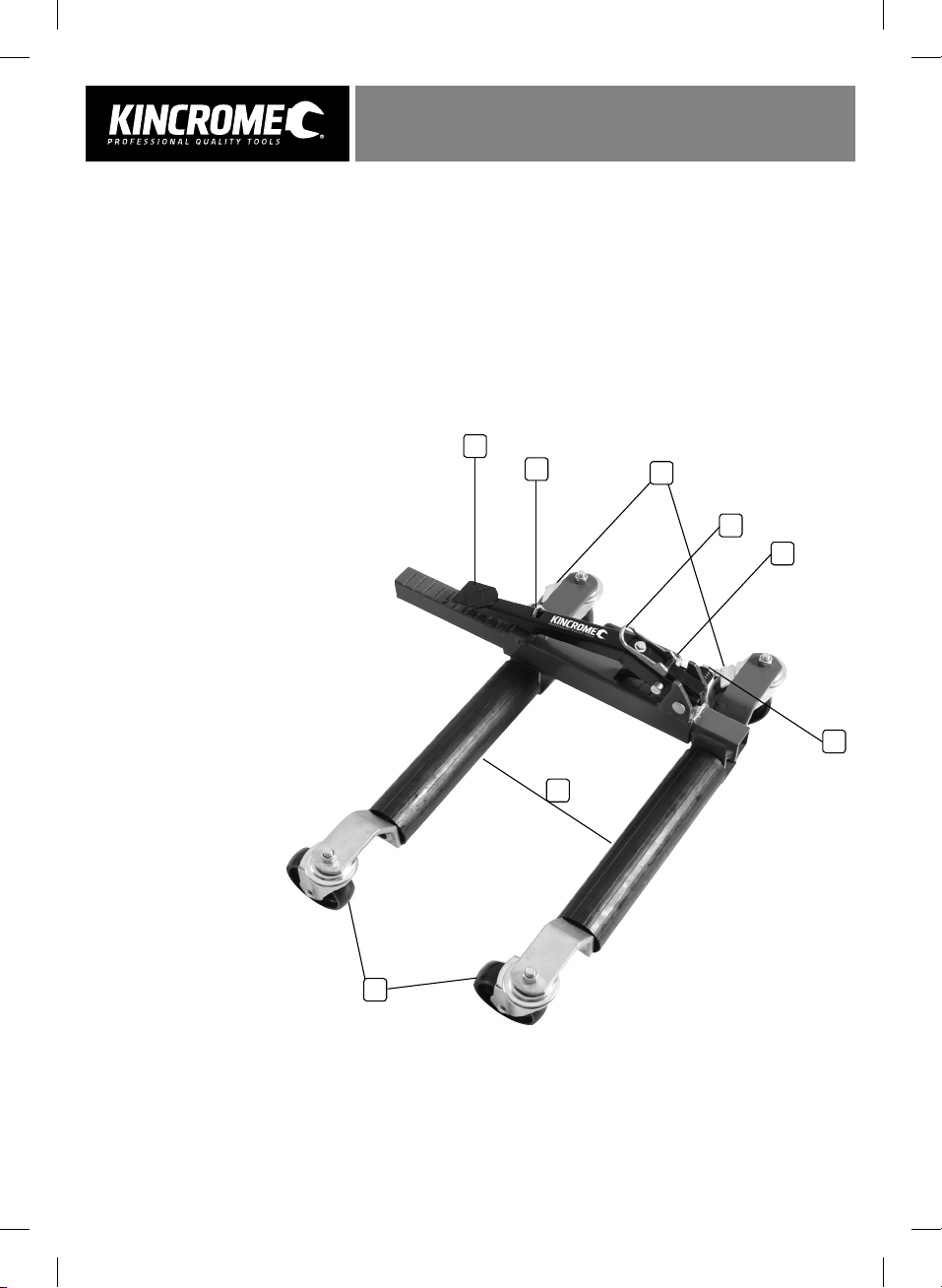

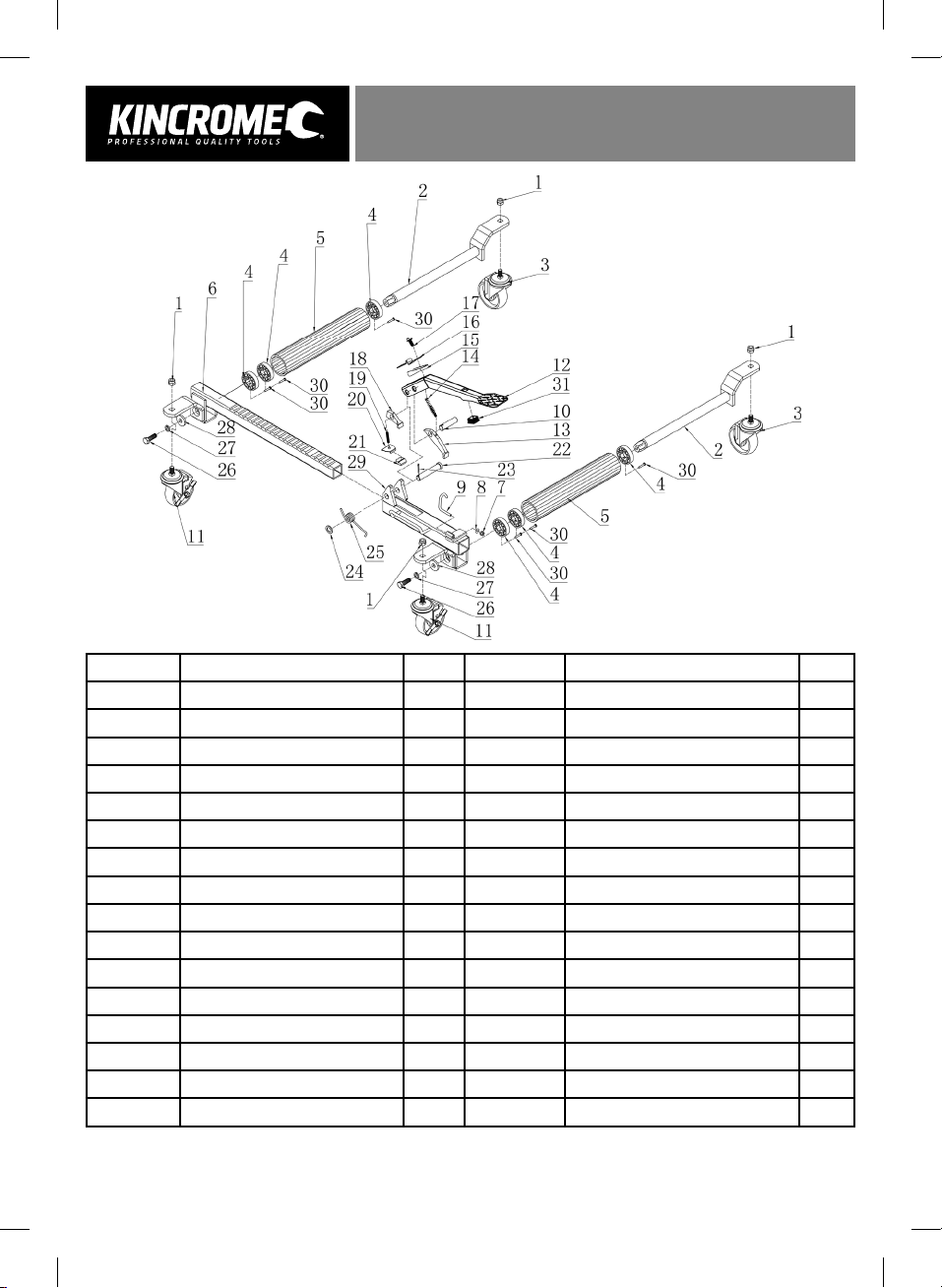

VEHICLE POSITIONING JACKS

General Safety Warnings

Save all WARNINGS and instructions for future reference.

Read and understand the entire contents of this manual before attempting to use the Vehicle Positioning Jacks.

The WARNINGS, cautions and instructions discussed in this instruction manual cannot cover all possible conditions or

situations that could occur. It must be understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

Preparing Work Area

Before using vehicle positioning jacks, it is important to prepare work area properly.

Follow this procedure each time the vehicle positioning jacks are used to help prevent property damage and or serious injury.

1. Keep work are clean, free of clutter and well lit. Cluttered and dark work places can cause accidents.

2. Keep children and bystanders away while operating this jack. Distractions can cause you to lose control, so visitors should

remain at a safe distance from the work area.

3. Be aware of all power lines, electrical circuits, water pipes and other mechanical hazards in your work area, particularly

those hazards below the work surface hidden from the operators view that may be unintentionally contacted and may

cause personal harm or property damage.

4. Be alert of your surrounds. Using Jacks in confined work areas may put you dangerously close to cutting tools

and rotating parts.

Personal Safety

1. Stay alert. Watch what you are doing and use common sense when operating the tool. Do not use the tool while tired or

under the influence of drugs, alcohol, or medication. A moment of inattention while operating the tool increases the risk

of injury to persons.

2. Dress properly. Do not wear loose clothing or jewellery. Contain long hair. Keep hair, clothing and gloves away from

moving parts. Loose clothes, jewellery, or long hair increases the risk of injury to persons as a result of being caught

in moving parts.

3. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the

tool in unexpected situations.

4. Use safety equipment. A dust mask, non-skid safety shoes and a hard hat must be used for the applicable conditions.

5. Always wear eye protection. Wear ANSI-approved safety goggles.

6. Have a qualified person maintain the equipment in good condition. Keep it clean for best and safest performance.

7. If the equipment needs repairing and/or there are parts that need to be replaced, have it repaired by authorized

technicians. Only use the replacement parts supplied by the manufacturer.

8. Dress properly. Do not wear loose clothing, dangling objects or jewellery.

9. Modifications must not be carried out or accessories added.

IMPORTANT SAFETY INFORMATION

1. DO NOT operate the jacks on surfaces which are not leveled. Jack must be used on hard, flat surfaces only. The vehicle may

shift as soon as the jacks lift the wheel from the surface.

2. DO NOT overload the jack beyond the Maximum Load Capacity which is 684kg per unit. Refer to your vehicles manual for

weight of your car.

3. DO NOT start the vehicles engine, or drive while the jacks are in use. Jacks are designed for hand

manoeuvring of vehicles only.

4. DO NOT use the jacks to lift tyres wider than 13” or 330mm. Refer to the side wall of your tyres.

(eg. 265/40R18 tyres are 265mm wide).

5. DO NOT attempt to push the jack over obstacles. They are designed to be used on hard, smooth and flat level surfaces only.

6. After lifting, be sure to ALWAYS secure the jacks in place with the locking pin. To lower the vehicle, remove the locking pin

before using the release valve.

7. Do NOT force the tool. Tools do a better and safer job when used in a manner for which they are designed. Plan your work,

and use the correct tool for the job.

8. Store idol tools. When tools are not in use, store in a dry, secure place out of reach of children. Inspect tools for good

working conditions prior to storage and and before re-use.

9. Modifications must not be carried out or accessories added. ONLY use accessories which are recommended by the manufacturer

for your model. Accessories that may be suitable for one tool may create a risk of injury when used on another tool.