3

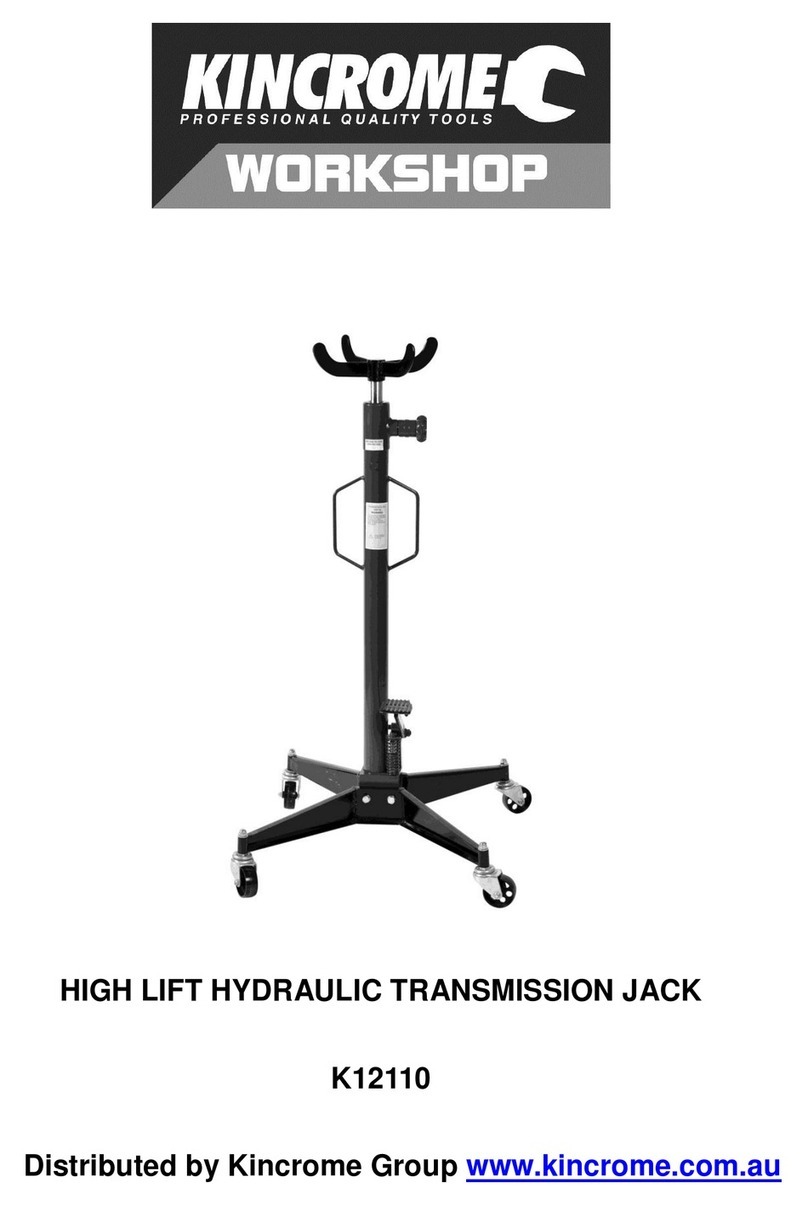

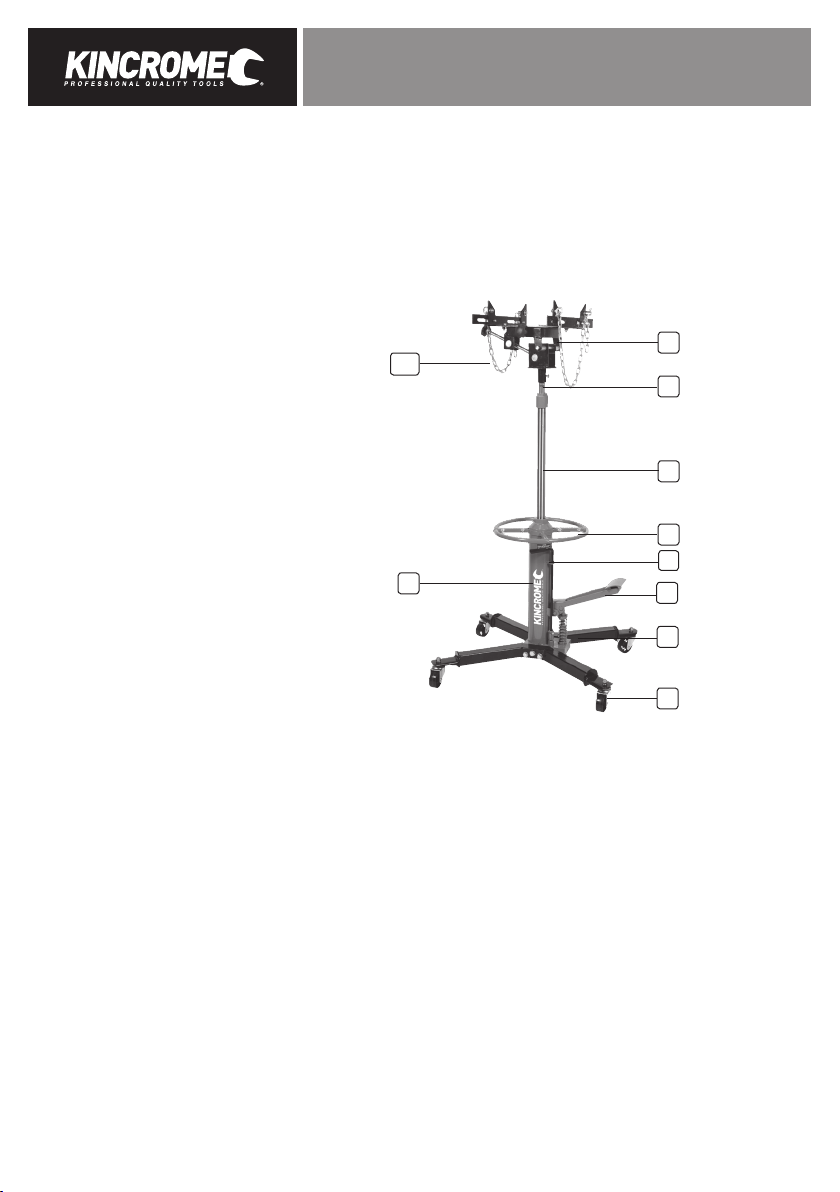

TRANSMISSION JACK 0.5 TONNE

General Safety Warnings

Save all warnings and instructions for future reference.

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may

result in serious injury or death.

IMPORTANT SAFETY INFORMATION

The use of a vehicle jack has inherent dangers to avoid risk of personal injury or property damage make sure you are fully

aware of the operating instructions for this product, the recommendations in the vehicle owners manual for jacking of

your vehicle prior to lifting the transmission. Do not exceed maximum lifting capacity of this jack. This jack is intended

for automotive use only. Be aware that large or heavy transmissions may exceed jack’s stated capacity check vehicle

owners manual or contact the vehicle manufacturer. Do not use for any other purpose except the raising and lower of

transmissions, Never use to raise any structure or building, Do not lift any human load and never ride on jack.

Preparing Work Area

Before using jack to lift transmission, it is important to prepare work area properly. Follow this procedure each time the jack is

used to help prevent property damage and or serious injury.

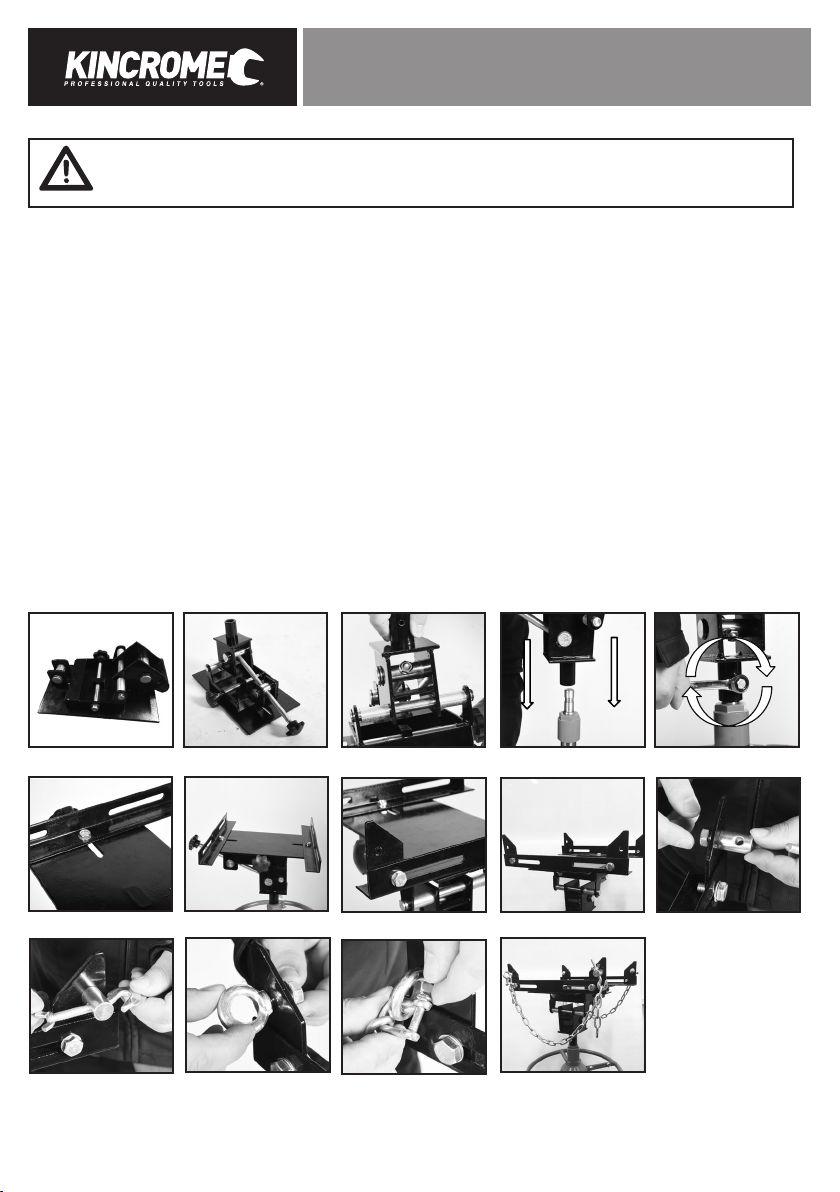

WARNING: The warnings, cautions and instructions discussed in this instruction manual cannot cover all

possible conditions and situations that may occur. It must be understood that common sense and caution are

factors which cannot be built into this product, but must be applied by the operator.

WARNING! Ensure all preliminary checks are carefully carried out before use of jack. Immediately repair

or replace damaged parts (use authorised service agent). Ensure use of genuine parts only.

Unauthorised parts may be dangerous and will invalidate the warranty.

WARNING! Use jack on level and solid ground, preferably concrete. Ensure the floor over which the jack

will be transported is swept clean.

DANGER! DO NOT use on tarmac, or any other soft surface as jack may sink or topple. Serious injury may

result if ignored.

DANGER! If jack tips or leans Stop what your are doing. MOVE QUICKLY TO A SAFE DISTANCE. DO NOT

TRY TO HOLD OR STEADY JACK.

1. Use jack in a suitable work area. Keep the area clean and tidy and free from unrelated materials. Ensure there is

adequate lighting.

2. Before use ensure the gearbox weight and size does not exceed the capacity of the jack.

3. Ensure the vehicle is raised and stabilised at the correct height before attempting to move the jack

under the vehicle.

4. Ensure the jack saddle is fully lowered and is clean, dry, and oil free before attempting to transport the jack with

or without a load.

5. Keep all unauthorised persons away from the jack during lifting and lowering and when in transit.

6. Maintain correct balance and footing. Ensure the floor is not slippery and wear non slip shoes.

7. Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery, and contain/tie back long hair.

8. WARNING! Ensure that the load is placed level and centrally on the jack saddle and that it is fixed in place before

attempting to lift, lower or transport the load.

9. The lowering speed will vary according to the weight of the load and the release valve setting. Diligence is required

in ensuring that you continually monitor the operation until completed. Should the jack make any abnormal

sounds during use, STOP IMMEDIATELY and contact your local service agent.

10. DO NOT operate the jack if any parts are damaged or missing.

11. DO NOT exceed the rated capacity of the jack.

12. DO NOT raise/lower vehicle lifting platform whilst the transmission jack is being used.

13. DO NOT transport the jack with/without a load, with the saddle in the raised position.

14. DO NOT get the jack wet, or use it in damp or wet locations or areas where there is condensation.

15. DO NOT operate the jack when you are tired or under the influence of alcohol, drugs or intoxicating medication.

16. DO NOT lift or support vehicles with the jack and do not use the jack as a load sustaining device.

17. DO NOT use the jack for any purpose other than removal, transportation and the installation of transmissions.

18. DO NOT make any modifications to the jack.

19. DO NOT adjust, or tamper with, the safety valve.

20. DO NOT remove any labels from the jack.