kincrome K12066 User manual

Other kincrome Jack manuals

kincrome

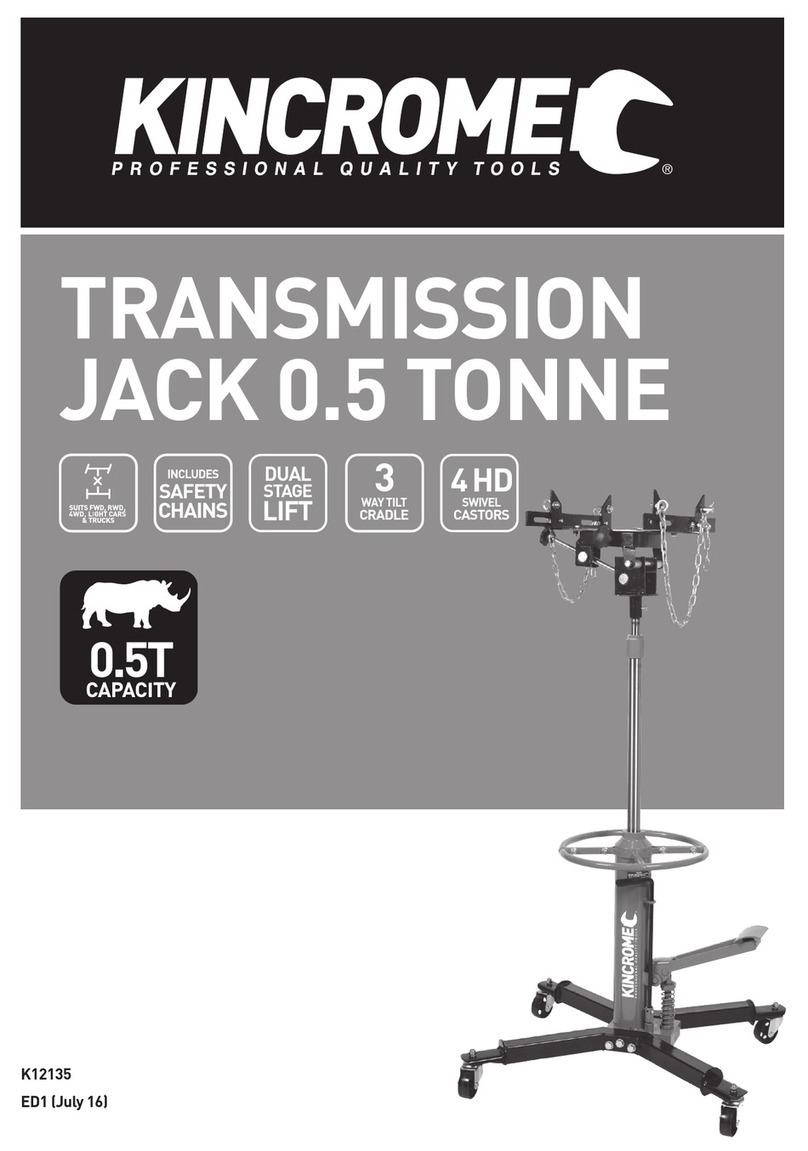

kincrome K12134 User manual

kincrome

kincrome K12054 User manual

kincrome

kincrome K12204 User manual

kincrome

kincrome K12068 User manual

kincrome

kincrome K12190 User manual

kincrome

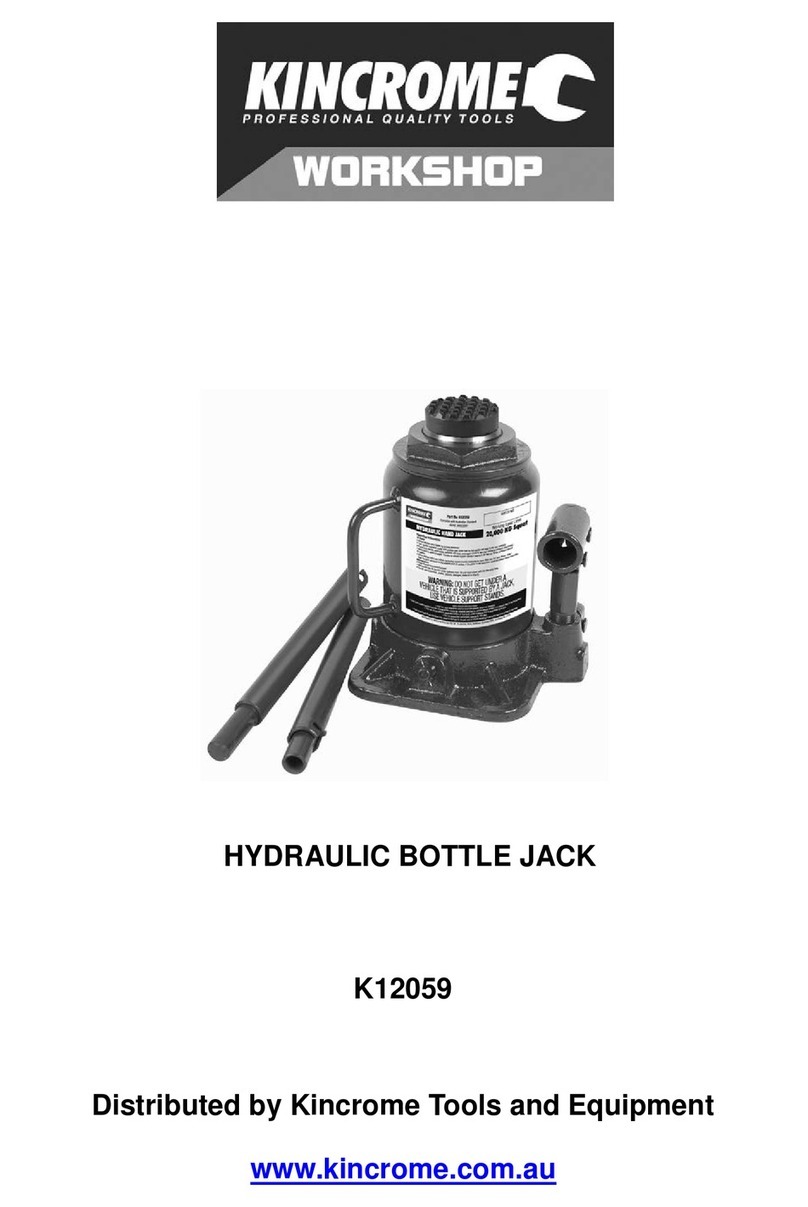

kincrome Workshop K12059 User manual

kincrome

kincrome K12058 User manual

kincrome

kincrome K12162 User manual

kincrome

kincrome K12060 User manual

kincrome

kincrome K12067 User manual

Popular Jack manuals by other brands

Omega Lift Equipment

Omega Lift Equipment 18122C Operating instructions & parts manual

Pittsburgh

Pittsburgh 58816 Owner's manual & safety instructions

Unimec

Unimec TP Assembly instructions

Sonic

Sonic 4800703 instructions

BGS technic

BGS technic 70039 instruction manual

TradeQuip

TradeQuip 1128T owner's manual

VEVOR

VEVOR TJD-12000SP-F quick start guide

ULTIMATE SPEED

ULTIMATE SPEED URW 2 A1 HYDRAULIC TROLLEY JACK operating instructions

Stels

Stels 51131 user manual

Valex

Valex 1650520 Translation of the original instructions

Clarke

Clarke CTJ2500QLG Operating & maintenance instructions

Pfaff

Pfaff Merkur M0 Operating instruction