OPERATING HYDRAULIC BODY REPAIR KIT

Preparing Work Area

Before using the body repair kit, it is important to prepare work area properly. Follow this procedure each time

the repair kit is used to help prevent property damage and or serious injury.

1.) Thoroughly inspect body repair kit for damage or wear before each use. Briefly test operation of unloaded

hydraulic ram before using to work on any job. If ram is damaged or is malfunctioning DO NOT USE until

the problem is corrected.

2.) Consult owner’s manual for safety precautions correct use and recommended procedures before using

the body repair kit. The working load limit of the hydraulic ram is 10000 kg. NEVER EXCEED

WORKING LOAD LIMIT OF HYDRAULIC RAM. Utilisation of multiple connections also reduces the

working capacity of the tool.

3.) Clear children and others from work area before using the body repair kit. Another adult should be

nearby for extra safety and assistance but must be clear of repair area as it is used.

4.) Never use to compress or bend objects that are not securely attached and could be ejected from their

position. Do not apply force to objects that could shatter.

5.) Clear obstructions from work area. Working in tight or cluttered work areas is dangerous.

6.) Ensure Body repair kit and operator are on solid, level ground such as paved or concrete driveway or

garage floor. Uneven or sloped surfaces create hazardous working conditions and may dangerously

impede the function of the body repair kit.

Using the Body repair kit

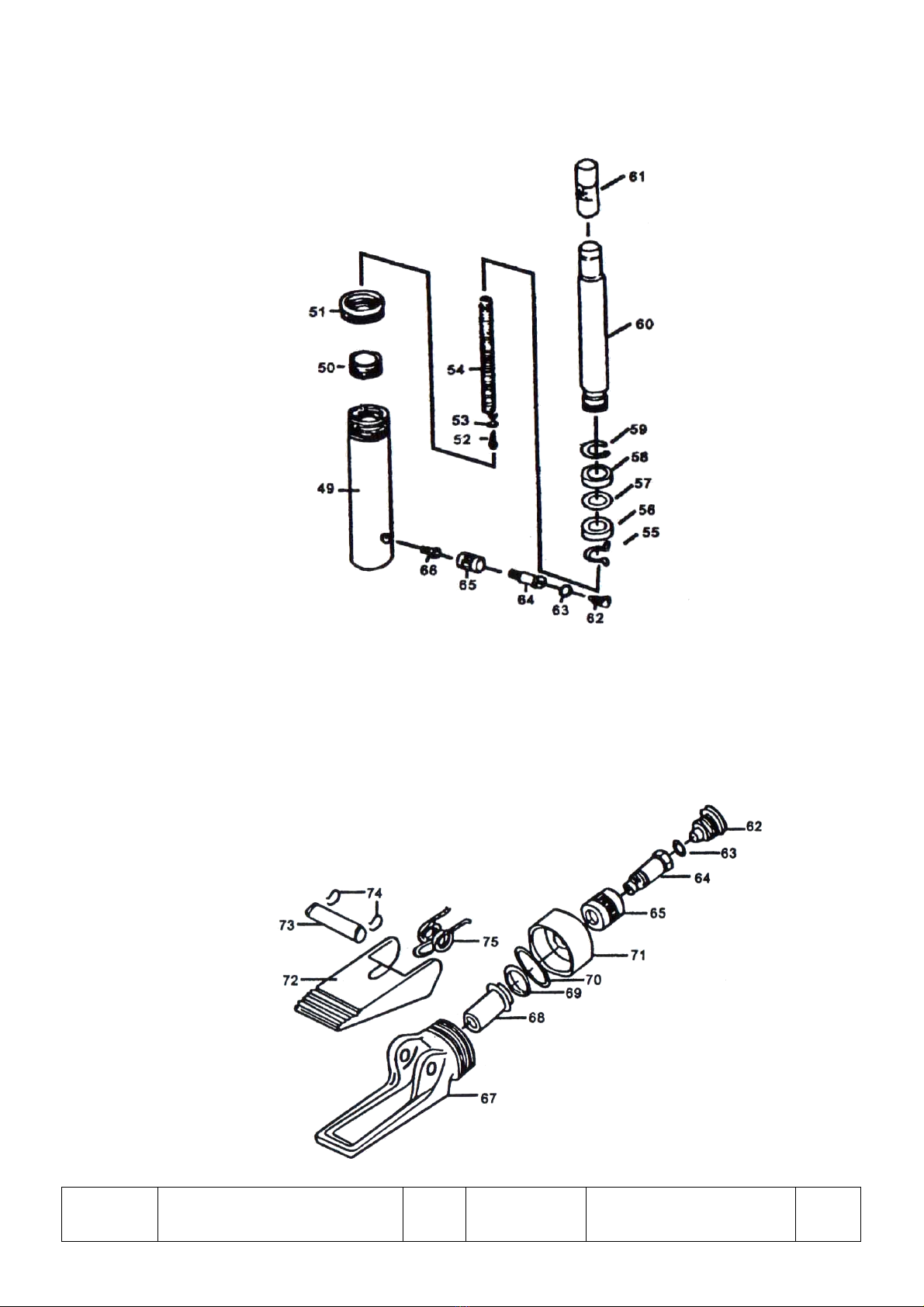

This hydraulic body repair kit comes with 14 accessory parts to allow for wide variety of applications. The

body repair kit is designed to repair and push automotive panels and assemblies.

1.) Place the body repair kit pump on a smooth surface.

2.) Select the correct part for the job to be done. The wrong accessory will create a potentially dangerous

situation.

i. The extensions 02-01, 02-02, 02-03, 02-04, use to achieve desired length, Caution the

longer the reach the lower the capacity.

ii. The base 03 normally used on the fixed end to spread the force

iii. Ram toe 04 and 05 attached to the ram to apply force where the ram head won’t fit directly in

the available space.

iv. Wedge head 06 suitable for creating gaps, applying high force to specific area

v. Cleft Cap 07 used to spread the force on curved surfaces

vi. Male connector 08 for attaching female end of the ram to a base tool

vii. Serrated cap 09 used on pushing end to prevent slip

viii. Rubber head 10 used to push out dents with minimal damage to the panel surface