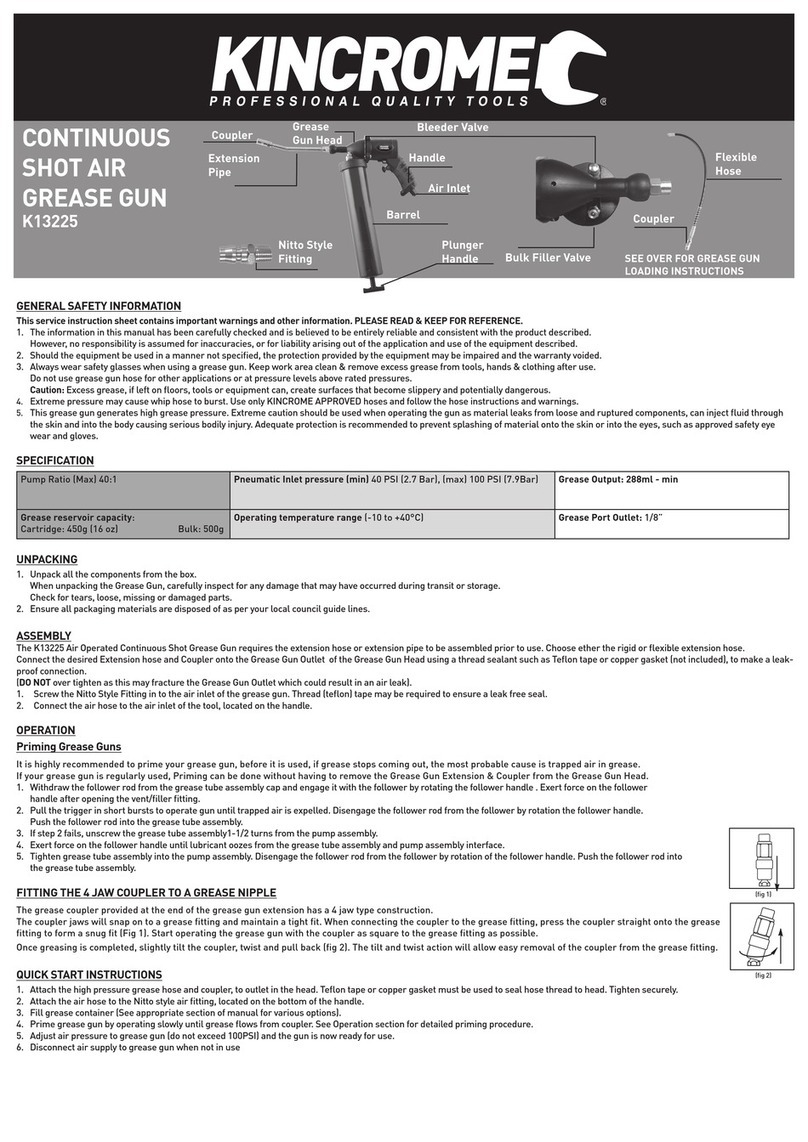

Bearing Packer Operation

1. Fill your K1705 Bearing Packer 2/3’rds full of grease, remove the Plunger Cone (5) from the Bearing Retainer (4) by rotating the Plunger Cone (5) anti-clockwise (Fig 6).

2. Fit your bearing over the Grease Nipple (2) with the bearing sitting over the holes in the Bearing Retainer (4) (for tapered bearing ensure the tapered end is facing down (4) (Fig 7) .

3. Refit the Plunger Cone (5) to the Bearing Retainer Shaft (3) by screwing it on clockwise, until hand tight.

4. Once the bearing is securely pressed down via the Plunger Cone (5), you can begin pushing down to feed the fresh grease through your bearing (Fig 8).

Note: If you are using high temp grease, you may need to use a vice to push the extra thick grease through the bearing (refer below to “Using The Bearing Packer With A Vice) .

5. Once fresh grease has been pushed through the bearing, unscrew the Plunger Cone (5) anti-clockwise and remove the bearing (Fig 9).

6. Using your hands, push additional grease in to the side of the bearings, to ensure it’s fully packed and wipe away excess grease (Fig 10).

7. Follow steps 2-6 if you wish to pack additional bearings.

Note: The Kincrome K1705 can pack up to 50+ bearings before needing to be refilled.

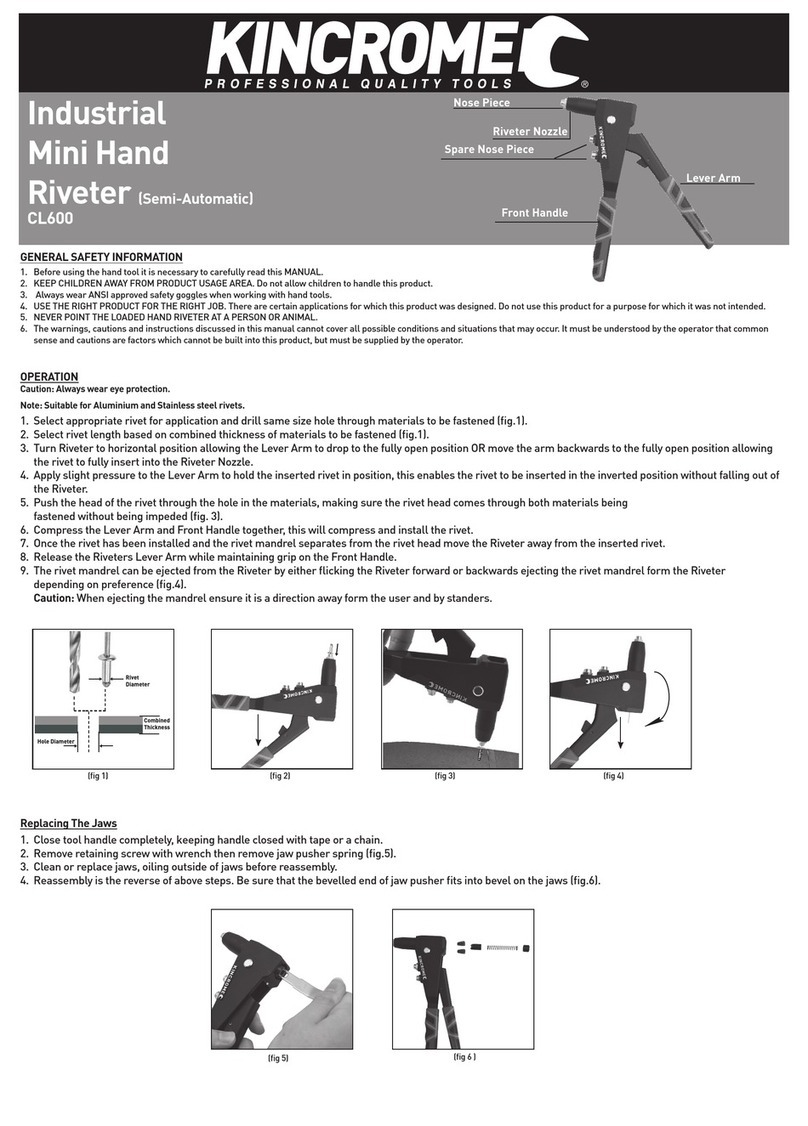

Using The Bearing Packer With A Vice

1. Repeat steps 1-3 from the “Bearing Packer Operation” part of the manual, located above.

2. Once the bearing is secured pressed down via the Plunger Cone (5), mount the Bearing Packer into your vice and tighten the vice so it is secured (Fig 11).

3. Tighten the vice slowly, which will effortlessly push the fresh grease through your bearing, continue tightening the vice until only fresh grease oozes

from the bearing (Fig 12) (do not overtighten).

4. Release the vice and remove the Bearing Packer, unscrew the Plunger Cone (5) anti-clockwise to remove the bearing (Fig 13).

5. Push additional grease in to the side of the bearings, using your hands to ensure it’s fully packed and wipe away excess grease.

Maintenance & Storage

The K1705 Kincrome Bearing Packer should be stored in a cool and dry area, out of reach of children.

Always ensure that your Dust Cap (6) has been refitted before storing, this will keep dust and debris out of your Bearing Packer.

Spare Parts

No Spare parts are stocked or available for the K1705 Bearing Packer.

Australian Office Contact Details UK Office Contact Details

Phone: 1300 657 528 Mail: Kincrome UK Ltd PO Box 646 Eastleigh SO50 ONA

Fax: 1300 556 005 Email: enquiries@kincrome.com.au

Email: enquiries@kincrome.com.au Website: www.kincrome.com.au

Website: www.kincrome.com.au

Warranty given by Kincrome Tools & Equipment Pty Ltd of 3 Lakeview Drive, Caribbean Park, Scoresby, Victoria, Australia (Tel +61 3 9730 7100) If

this product has materials or workmanship defects (other than defects caused by abnormal or non warranted use) you can, at your cost, send the

product to place of purchase, an authorised Kincrome service agent or one of Kincromes addresses for repair or replacement. Your rights under

this warranty are in addition to any other rights you have under the Australian, United Kingdom & Ireland Consumer Law or other applicable laws.

Our goods come with guarantees that cannot be excluded under the Australian, United Kingdom & Ireland Consumer Law. You are entitled to a

replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have

the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure. For further details

please visit www.kincrome.com.au or call us. Due to minor changes in designor manufacture, the product you purchase may sometimes differ

from the one shown on the packaging.

SCAN FOR

HOW TO VIDEO

(Fig 6) (Fig 7) (Fig 8)

(Fig 9) (Fig 10)

(Fig 11) (Fig 12) (Fig 13)