2

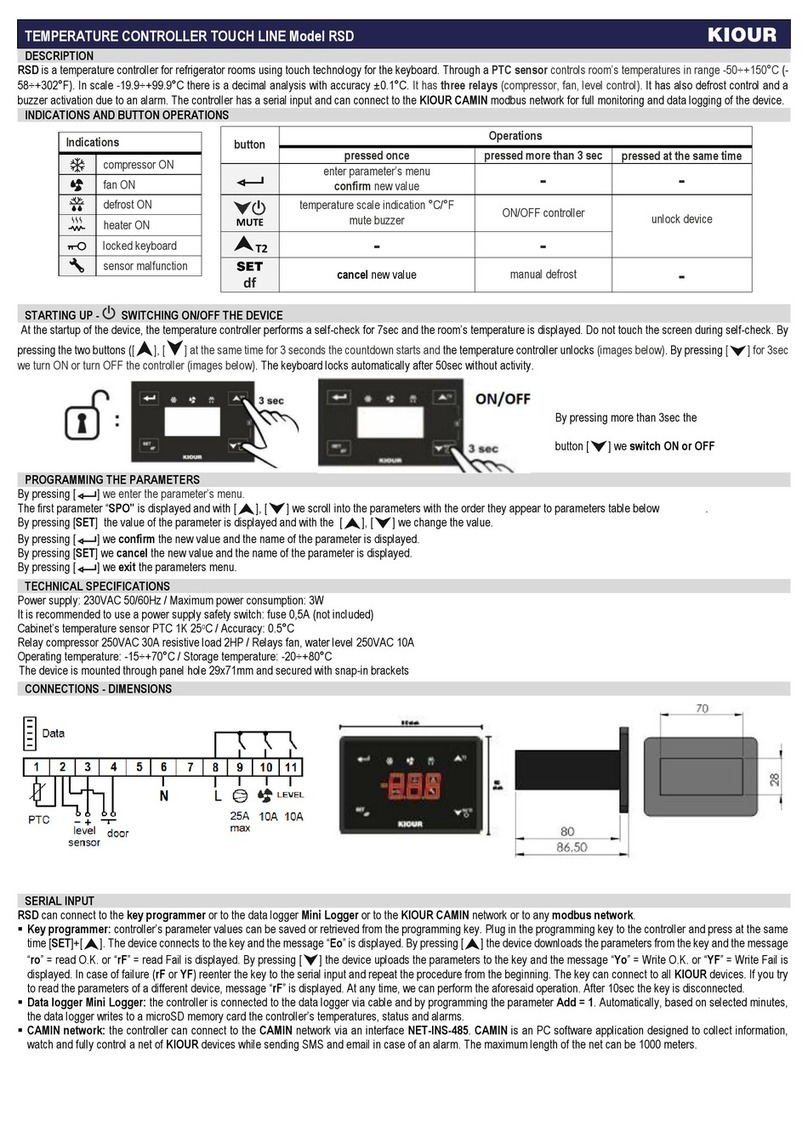

VD1T connects via serial input to the cloud and the online CORTEX platform or to a local computer with the CAMIN program or to the memory key or to the Mini Logger or to

any Modbus network.

CAMIN program: local connection and monitoring - recording and management of the thermostat through the CAMIN program installed on a local computer.

Mini Logger recorder: The thermostat can be connected to the recorder and record based on selected minutes on a microSD memory card, its temperatures and the

state of the relays and alarms. It is connected via a cable to the serial input and we program the parameter Add = 1.

Memory key: the parameter values are stored in the memory key or recorded by it in the thermostat.

When the parameter rHC = 2, the relay operates in heating mode based on the parameter Hod while “SET”is displayed. By pressing the relay is activated and the

indication “rUn” is displayed. By pressing we see successively the temperature of the second sensor, if it is activated, as well as the remaining time. When time elapses,

the relay is deactivated and “End” is displayed on screen. By pressing again, the procedure starts over. The thermostat constantly controls the relay based on the adjusted

Set Point (SPo). If SPo changes during “rUn”, automatically the control of the relay is adjusted. If timer “Hod”changes during “rUn”mode, it will not change until the next

running cycle.

Smart defrost function: The thermostat finds the ideal operating temperature of the evaporator and if the evaporator operates at a temperature lower than the ideal temperature

constant dSt than the ideal, and for a time longer than the time constant dS1, defrost begins.

Smart defrosting works in parallel and independently of conventional defrosting. It is automatic and the thermostat decides when to defrost and for how long. It is necessary

to connect the evaporator sensor and set the parameter 8, SOI = 0. The two types of defrosts - smart and conventional - can operate simultaneously based on the respective

settings. By enabling smart defrosting, the conventional defrost can be set to operate safely - for example one defrost every 48 hours. This time is renewed each time an

automatic defrost is performed.

Activate the smart defrost from parameter 24, dSE = 1. It is recommended to start the refrigerator, to make a defrost cycle, where it is activated with parameter 25, dSb = 1.

The time constants dS1 and temperature dSt are formed based on the image of the element: if we observe ice, we reduce the constants.

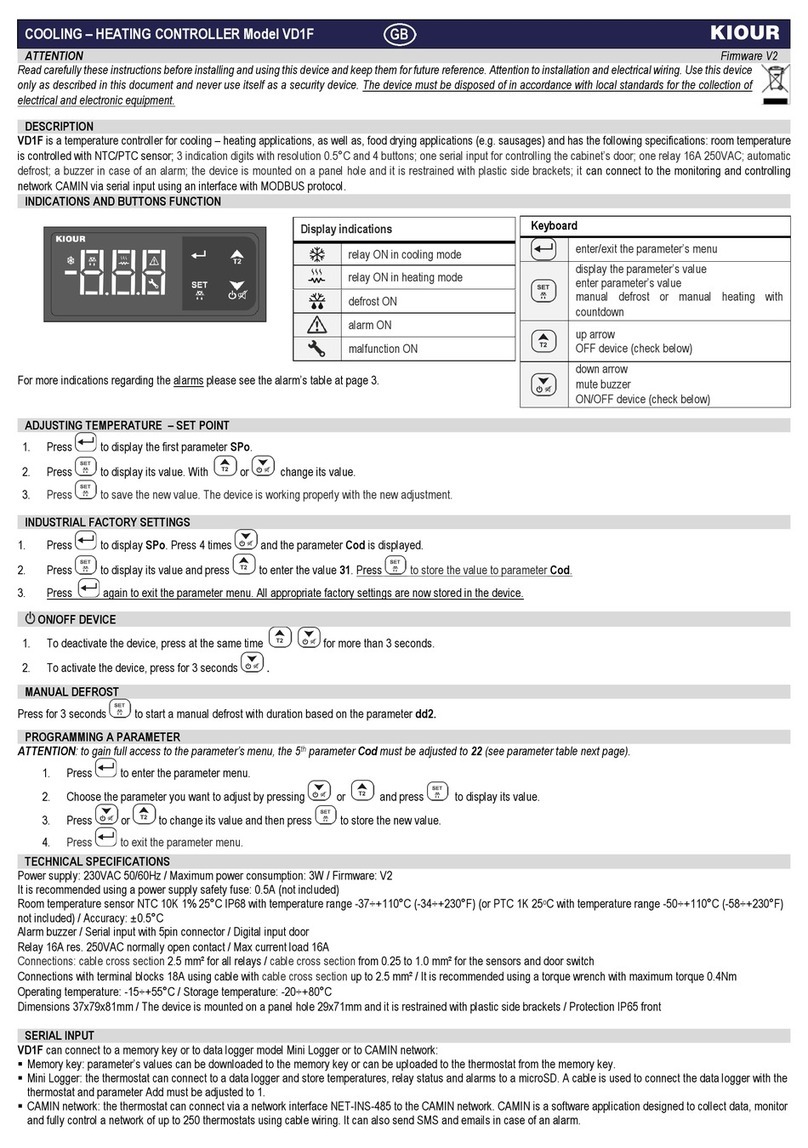

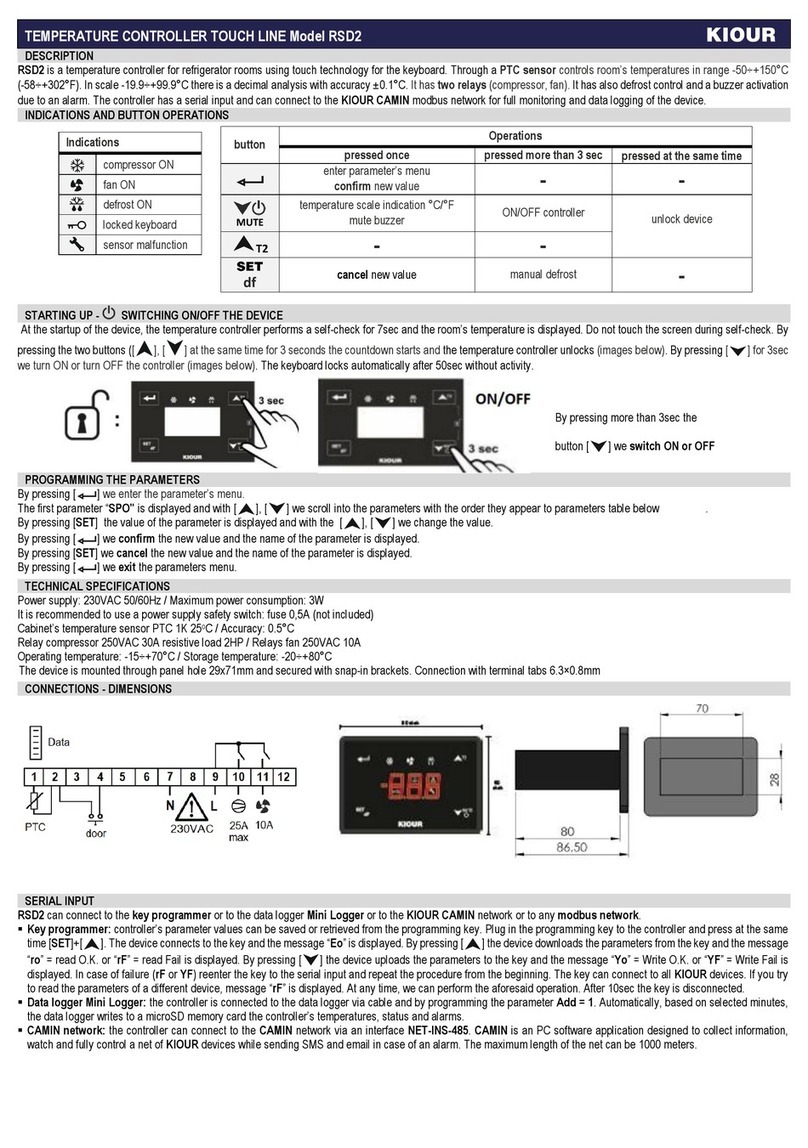

ELECTRICAL DIAGRAM - DIMENSIONS

ATTENTION: according to safety standards, the device must be properly positioned and protected from any contact with electrical parts. The device must be fastened in such a way that it

cannot be removed without the use of tools. Disconnect the main safety switch of the installation before proceeding to any maintenance. Disconnect the power supply of the device before

proceeding to any maintenance. Do not place the device near heat sources, equipment containing strong magnets, in areas affected by direct sunlight or rain. Prevent electrostatic discharges

and sharp objects from been inserted to the device. Separate signal cables from power supply cables to prevent electromagnetic disorders. Signal cables must never be in the same pipe with

the power supply cables. ATTENTION: Read carefully the technical specifications and make sure that the working conditions are appropriate. According to safety standards, the device must

be fastened in such a way that it cannot be removed without the use of tools

Dimensions are in mm. The device is mounted on panel hole with cut 29x71mm and restrained with plastic side brackets

Parameter SOI = 1: door switch or

SOI = 0: evaporator sensor terminals 4-5

SET POINT: room temperature setting

Password in the following parameters Cod = 22

ANALOG INPUTS - TEMPERATURE

Differential of room temperature SPo (thermostat delay)

Lower setting limit of SPo

Maximum setting limit of SPo

Temperature indication as integer or decimal, where 0 = integer / 1 = decimal

Sensor type NTC/PTC

0 = PTC / 1 = NTC

Set 2nd input as NTC / PTC evaporator sensor or door switch:

0 = evaporator sensor / 1 = door switch

Selecting one setting automatically turns off the alarms and features of the other setting.

Delay in displaying the actual room temperature on the screen when the door is opened

Temperature measurement unit: toggling between °C/°F do not adjust the SPo automatically, it must be

changed by the user :

0 = °C / 1 = °F

lower alarm limit temperature of the cabinet

higher alarm limit temperature of the cabinet

Time delay in activating “AΗi”, “ΑLo” and the buzzer among them.

This setting does not apply to sensor failure “LF1”, “LF2” and door alarm “dor”.

DIGITAL INPUT –DOOR SWITCH

Door switch operation

0 = OFF / 1 = NC (normally close contact) / 2 = NO (normally open contact)

In heating mode the door control is deactivated

FOOD DRYING APPLICATIONS (e.g. SAUSAGES) - HEATING MODE WITH COUNTDOWN