KLAY-INSTRUMENTS 2000-SAN Series User guide

Other KLAY-INSTRUMENTS Transmitter manuals

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS TT-2000 Series User manual

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS DP-4000 Series User manual

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS PROFIBUS PA 4000 Series User manual

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS DP-4000 Series User manual

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS 2000-SAN Series User manual

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS 2000 Series User manual

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS TT4000 Series User manual

KLAY-INSTRUMENTS

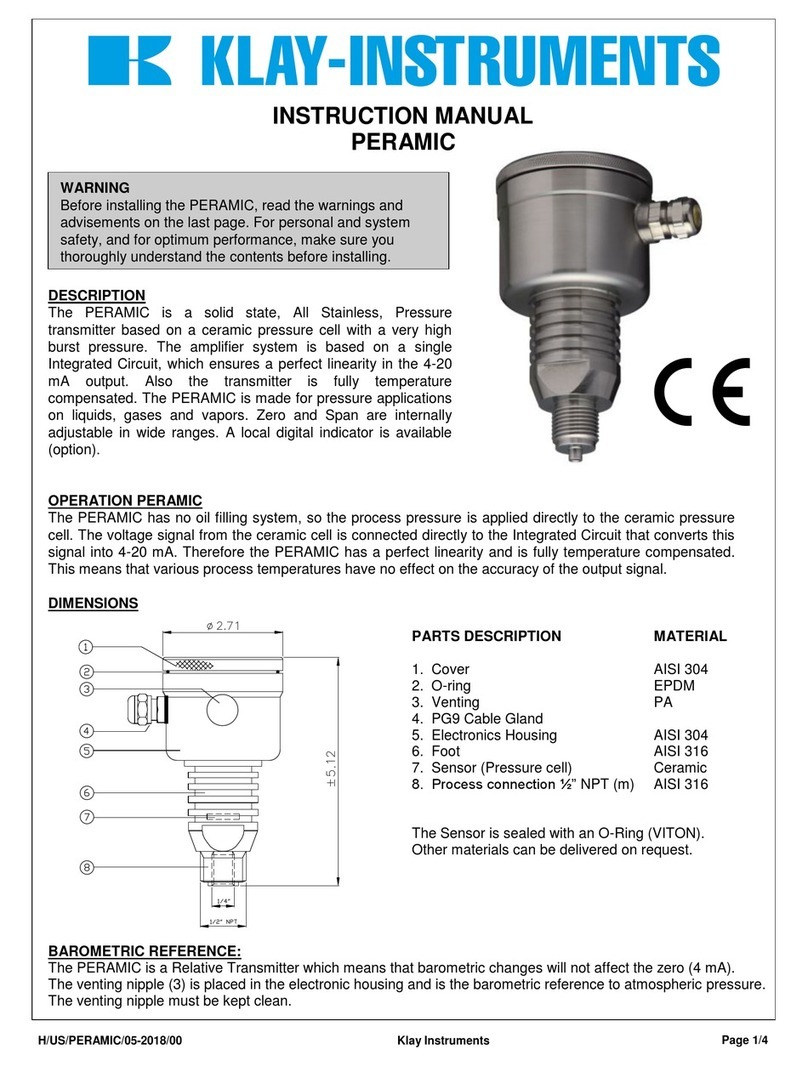

KLAY-INSTRUMENTS PERAMIC User manual

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS 8000 Series User guide

KLAY-INSTRUMENTS

KLAY-INSTRUMENTS 2000-VALVE-RANGE Series User manual

Popular Transmitter manuals by other brands

Geo

Geo Web Pack quick start guide

Inovonics

Inovonics EchoStream EN1210W installation instructions

IKONNIK

IKONNIK KA-6 quick start guide

Rohde & Schwarz

Rohde & Schwarz SR8000 Series System manual

Audio Technica

Audio Technica UniPak ATW-T93 Installation and operation

NIVELCO

NIVELCO EasyTREK SCA-300 Series Programming manual