H/US/8000/03-2018/00 Klay Instruments

CONTENTS

SECTION PAGE

1 Introduction 2/8

1.1 Description Series 8000-SAN 2/8

1.2 Description Series 8000 2/8

1.3 Barometric reference 2/8

2 Dimensional Drawing 3/8

2.1 Dimensional Drawing 8000-SAN 3/8

2.2 Dimensional Drawing 8000 3/8

2.3 Installing Weld-on nipple 3/8

3 Installing Transmitter 4/8

3.1 Installing Transmitter 8000-SAN 4/8

3.2 Installing Transmitter 8000 4/8

3.3 Mounting Position 4/8

3.4 Mounting Position Effect 4/8

3.5 Calibration 4/8

SECTION PAGE

4 Wiring 5/8

4.1 Digital Local Indicator 5/8

4.2 Hazardous area (Ex) 5/8

4.3 Functional Safety –SIL 6/8

4.4 Traceability year of manufacturing 6/8

4.5 CE / EMC-rules 6/8

4.6 External Load 6/8

5 Specifications 7/8

6 Precautions and Warnings 8/8

Attachment: EU-Declaration of conformity

1 INTRODUCTION

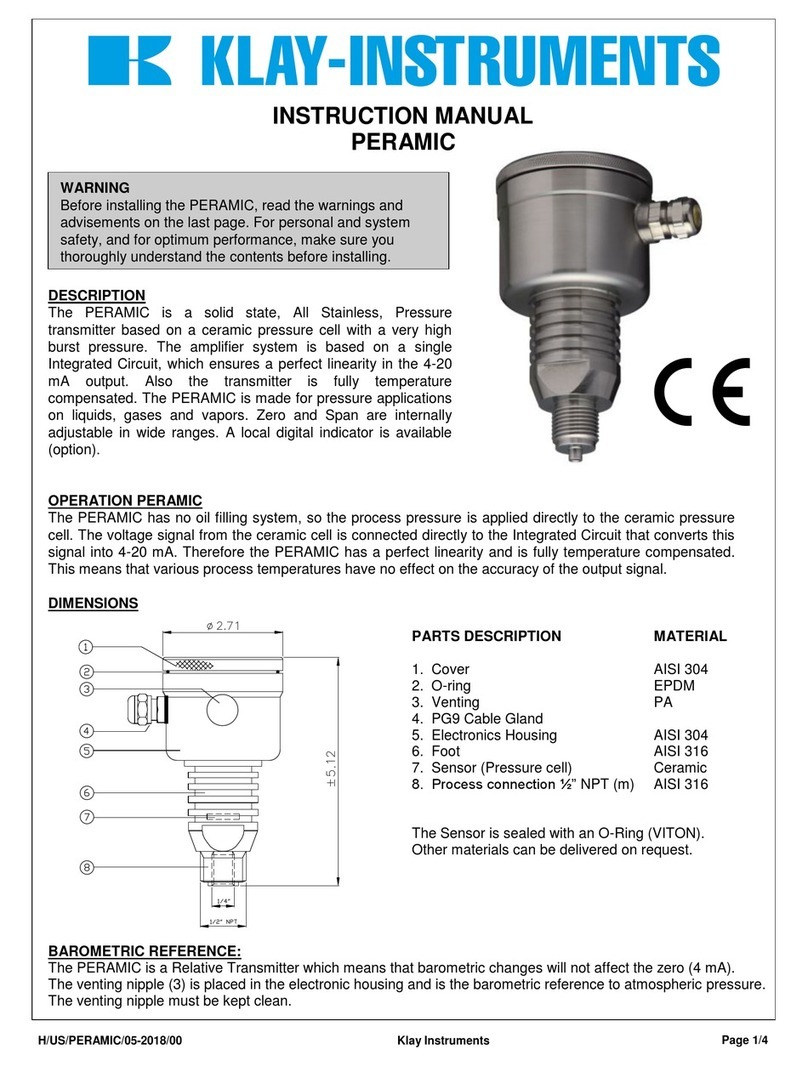

The Series 8000 and Series 8000-SAN are solid-state pressure and level transmitters based upon a bridge resistive

silicon sensor, with a very high burst pressure. The sensor element is mounted in a stainless steel foot. A strong

stainless steel "flush" diaphragm protects the sensor from the process medium. Special oil fills the chamber

surrounding the sensor and transfers pressure from the flush mounted diaphragm to the sensor.

Pressure on the sensor element creates a very small deflection of the silicon substrate and bridge network. The

resulting strain in the silicon resistors causes a change in the bridge resistance that is proportional to the pressure

applied. The transmitter electronics detects this change in bridge resistance and converts it into 4-20 mA. The

amplifier system is based on a single Integrated Circuit, which ensures a perfect linearity in the 4-20 mA output.

The Series 8000 and 8000-SAN are available as SIL2, proven in use (Option G200).

1.1 DESCRIPTION SERIES 8000-SAN

The Series 8000-SAN are specially designed with a flush mounted diaphragm so they fully meet the needs of the

food, pharma and chemical industries. The Series 8000-SAN is available as 3-A version (Sanitary Standard - Option

G153) and EHEDG (Sanitary standard - Option G150). Standard the wetted parts are made of AISI 316, other

materials are available, like Hastelloy C. Various process connections can be delivered, such as Tri-Clamp (1.5” ,2”

and 3”), SMS (1.5” and 2”), dairy milk couplings (DN 25, 40 and 50), flanges (DIN and ANSI) and sanitary weld-on

nipples (ø 1.89, 2.44 and 3.35 inch.)

1.2 DESCRIPTION SERIES 8000

The Series 8000 are specially designed for the pulp and paper or similar industries, where clogging is a problem.

The very compact construction of the Series 8000 permits flush installation with the tank- or pipe wall. Standard the

wetted parts are made of AISI 316, a lot of other materials like Hastelloy C are available as an option.

All transmitters are fully temperature compensated, which means that various process temperatures have nearly no

effect on the accuracy of the output signal. When a failure occurs, the transmitter is repairable. However, for

optimum accuracy the transmitter has to be send back to the factory.

1.3 BAROMETRIC REFERENCE

The Series 8000 is in basic a so-called Relative Transmitter which means that barometric changes will not affect the

zero (4 mA). The venting is placed in the electronic housing and is the barometric reference to atmospheric

pressure. The venting must be kept clean.