1

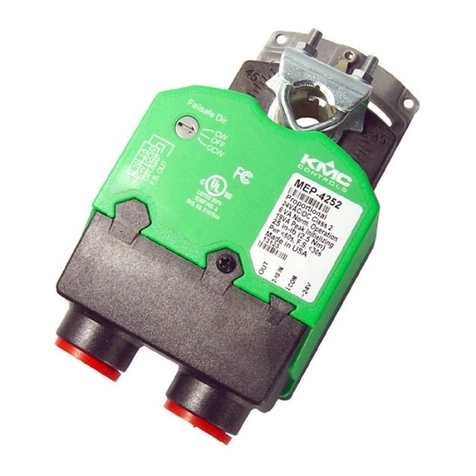

DESCRIPTION AND APPLICATION

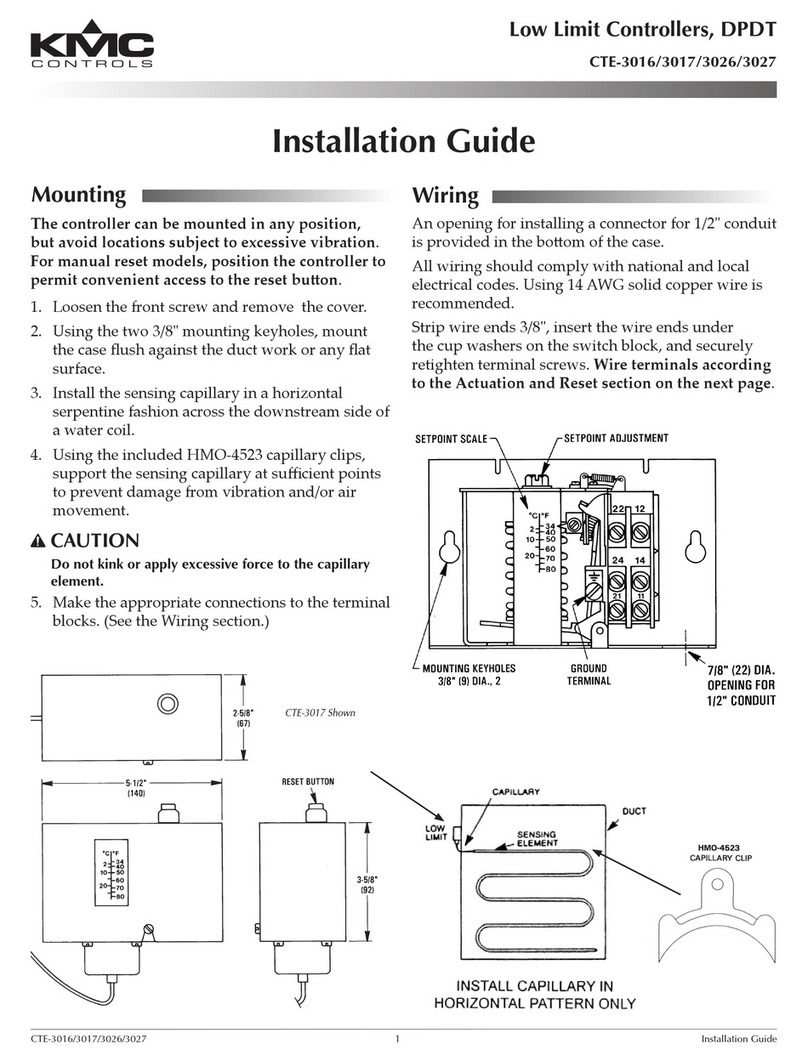

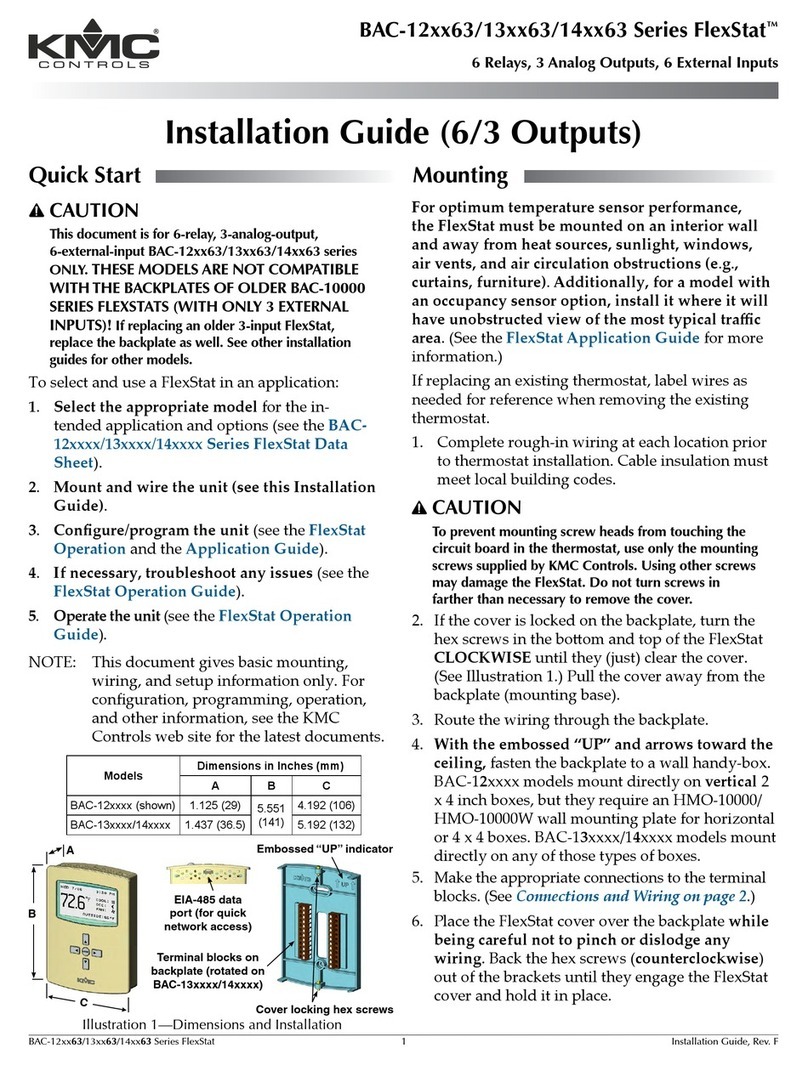

These compact but powerful direct-coupled ControlSet®

actuators provide 90° rotation within three seconds. A

minimum torque of 54 in-lb. is available over the 95° angular

rotation. These actuators are designed for dampers or

valves in critical HVAC, laboratory fume hood, and life-safety

applications.

Efcient, durable, capacitor-driven fail-safe operation (in

MEP-4652Q/4672Q) with switch-selectable direction provides

consistent torque in both powered and fail-safe modes.

The actuators offer proportional or two-position control.

Two-position control mode is designed for use with on/off

switches, thermostats, or controller outputs.

Proportional control mode accepts either a 0–10 or 2–10 VDC

control signal input from a thermostat or controller. With an

external 500 ohm resistor, a 0–20 or 4–20 mA control signal

is also accepted. A switch-selectable, 0–5 or 0–10 (or 1–5

or 2–10) VDC voltage feedback output is proportional to the

actuator position and is standard on all models. “Anti-jitter”

circuitry signicantly reduces hunting and needless wear

(from unnecessary miniscule position changes caused by

undamped analog input signals) on the actuator, valve, or

damper components. A user-initiated, auto-mapping feature

provides more precise equipment control by reassigning the

input signal range over a reduced rotation range. The feature

also provides “soft stall” protection (from stalling hard against

a physical stop) that extends actuator life.

MEP-4622Q and MEP-4672Q models also have two built-in

SPDT auxiliary switches for remote position indication or an

auxiliary equipment interface. One switch is fully adjustable (0

to 90°) and the other is xed at 10° from full CW direction. A

three-foot cable is included with the switches.

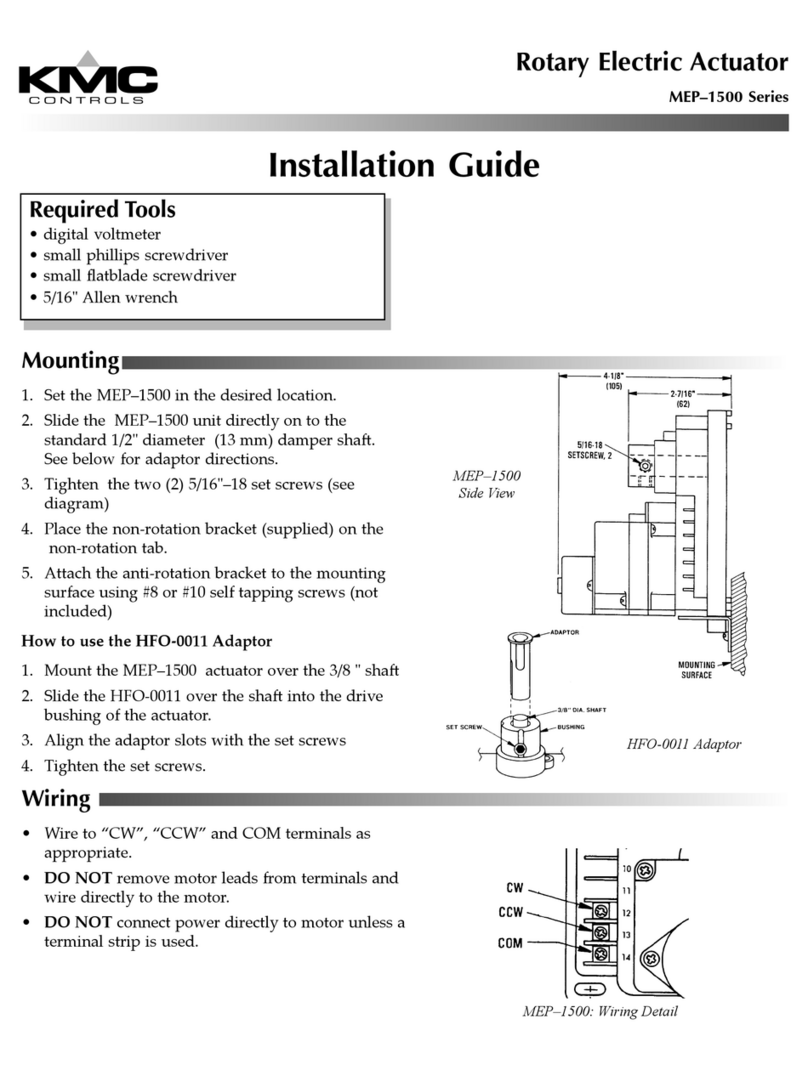

All actuators mount directly to 1/4- to 5/8-inch (6 to 16

mm) round shafts or 1/4- to 7/16-inch (6 to 11 mm) square

shafts, eliminating the need for expensive and complicated

linkages. A non-rotation bracket, to prevent lateral movement,

is included with each actuator. A gear disengagement button

allows easy manual positioning of the actuator.

Specifications and design subject to change without notice

FEATURES

◆Brushless DC motor technology

◆Each model provides proportional or two-position control

◆90° rotation within three seconds (powered or optional

fail-safe)

◆54 in-lb. is available over the 95° angular rotation

◆Optional fail-safe (in MEP-4652Q and MEP-4672Q models)

◆The fail-safe option has switch-selectable direction and

can be turned off temporarily for testing purposes or

permanently if desired

◆Proportional mode includes “anti-jitter” circuitry

◆Auto-mapping of the full input-signal range over a reduced

actuator stroke provides a “soft stall” protection feature

that extends actuator life

◆Switch-selectable 0/1–5 or 0/2–10 VDC feedback is stan-

dard on all models

◆MEP-4622Q and MEP-4672Q models have one fully adjust-

able and one xed built-in SPDT auxiliary switches

◆Direct mounting to standard shaft sizes, gear disengage-

ment button, and adjustable mechanical end stop

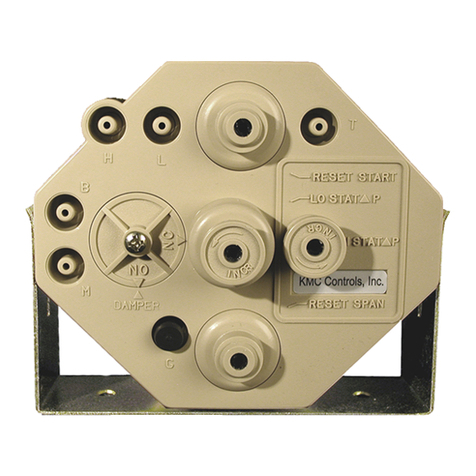

(Size Shown Relative

to a Quarter)

MEP-46xxQ Series

Quick-Running (3-Second) Actuators (54 in-lb.)