SensoGate WA131

3

Table of Contents

1 Safety............................................................................................................................................. 5

1.1 Intended Use ......................................................................................................................................................... 5

1.2 Personnel Requirements ................................................................................................................................... 5

1.3 Safeguards.............................................................................................................................................................. 6

1.4 Residual Risks ........................................................................................................................................................ 7

1.5 Safety Accessories................................................................................................................................................ 8

1.6 Hazardous Substances ....................................................................................................................................... 9

1.7 Operation in Explosive Atmospheres ........................................................................................................... 9

1.7.1 Possible Ignition Hazards During Installation and Maintenance.......................................... 9

1.7.2 Possible Ignition Hazards During Operation................................................................................ 10

1.8 Safety Training ...................................................................................................................................................... 10

1.9 Maintenance and Spare Parts.......................................................................................................................... 10

2 Product .......................................................................................................................................... 11

2.1 Package Contents ................................................................................................................................................ 11

2.2 Product Identification......................................................................................................................................... 11

2.2.1 Example of a Version ............................................................................................................................. 11

2.2.2 Product Code ........................................................................................................................................... 12

2.3 Nameplates ............................................................................................................................................................ 14

2.4 Symbols and Markings....................................................................................................................................... 16

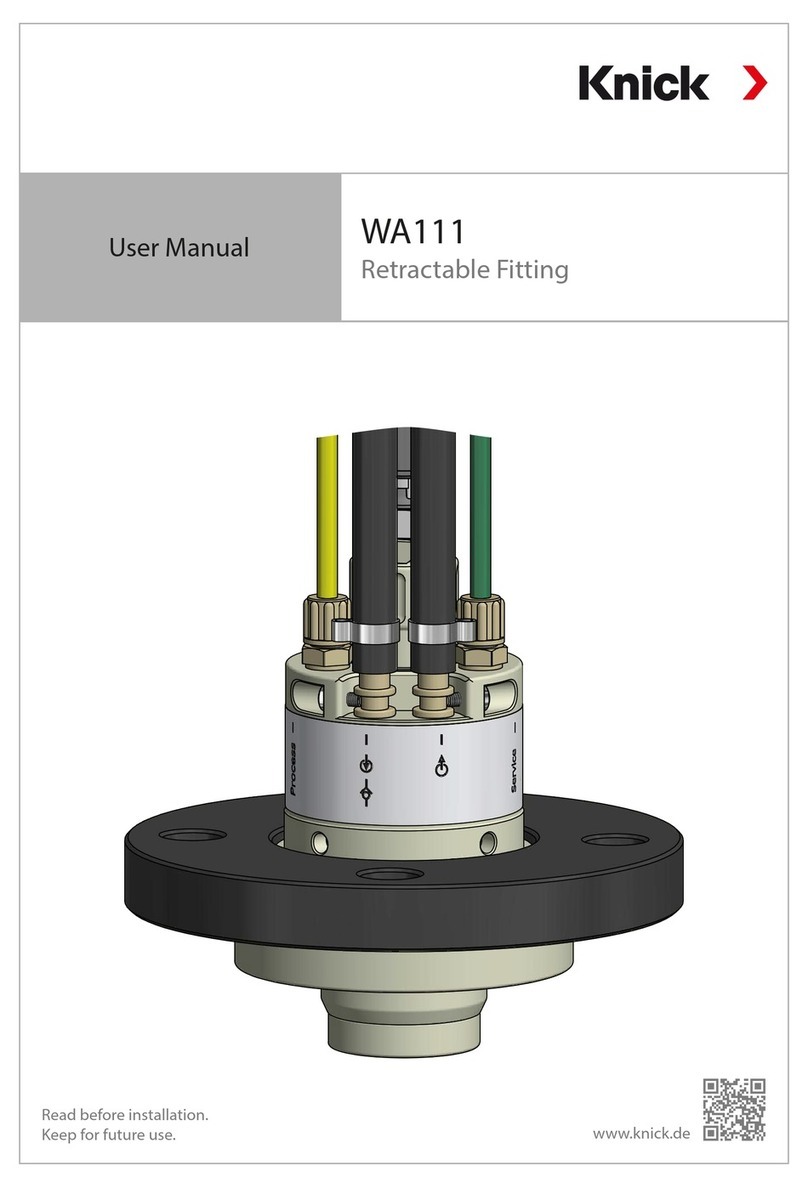

2.5 Design and Function........................................................................................................................................... 16

2.5.1 Retractable Fitting.................................................................................................................................. 17

2.5.2 Drives and Sensor Holders.................................................................................................................. 18

2.5.3 Process Connections ............................................................................................................................. 18

2.5.4 Immersion Tubes .................................................................................................................................... 19

2.6 Permissible Changes........................................................................................................................................... 19

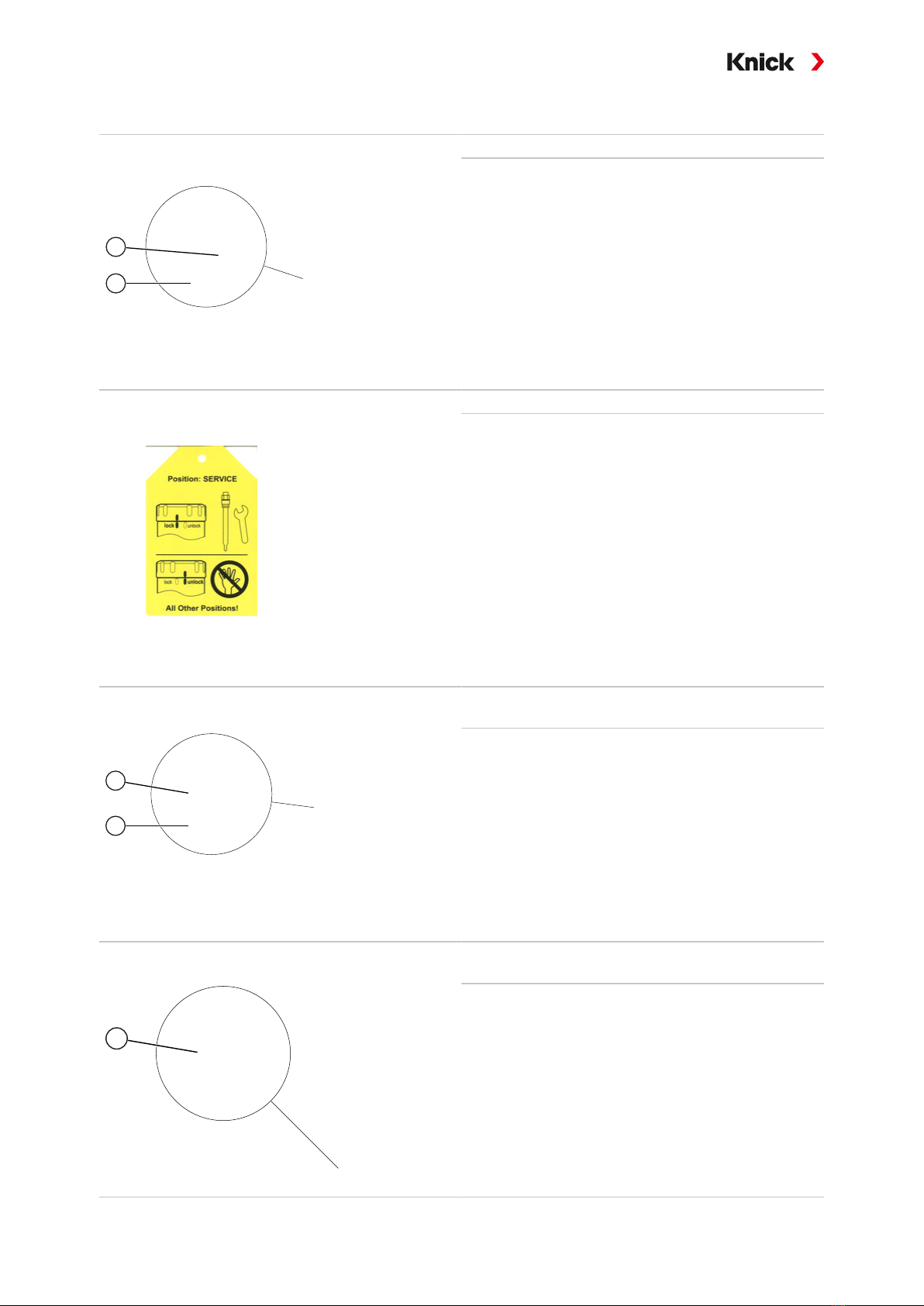

2.7 SERVICE/PROCESS Limit Positions ................................................................................................................. 20

2.7.1 Service and Process Position.............................................................................................................. 20

2.7.2 Limit Signals ............................................................................................................................................. 21

3 Installation .................................................................................................................................... 22

3.1 Retractable Fitting: Installation....................................................................................................................... 22

3.2 Safety Accessories: Installation ....................................................................................................................... 22

3.3 Outlet Hose: Installation.................................................................................................................................... 23

3.4 Inlet Hose (Option): Installation...................................................................................................................... 23

3.5 Pneumatic Control: Installation ...................................................................................................................... 24

4 Commissioning ............................................................................................................................. 25

5 Operation ...................................................................................................................................... 26

5.1 Moving into the Process Position (PROCESS Limit Position) ................................................................ 26

5.2 Moving into the Service Position (SERVICE Limit Position)................................................................... 26

5.3 Installing and Removing Sensors................................................................................................................... 27

5.3.1 Safety Instructions on Installing and Removing Sensors......................................................... 27

5.3.2 Solid-Electrolyte Sensor, Short Immersion Depth: Installation ............................................. 27