●Notes After Usage

●

Transmitter Battery Handling and Charging (separately available option)

Caution!

Enforcement matters

Caution!

Enforcement matters

Danger!

Enforcement matters

Danger!

Enforcement matters

●Do not touch engine, motor, ESC, etc. immediately after use as they may be hot.

※Doing so may lead to burns.

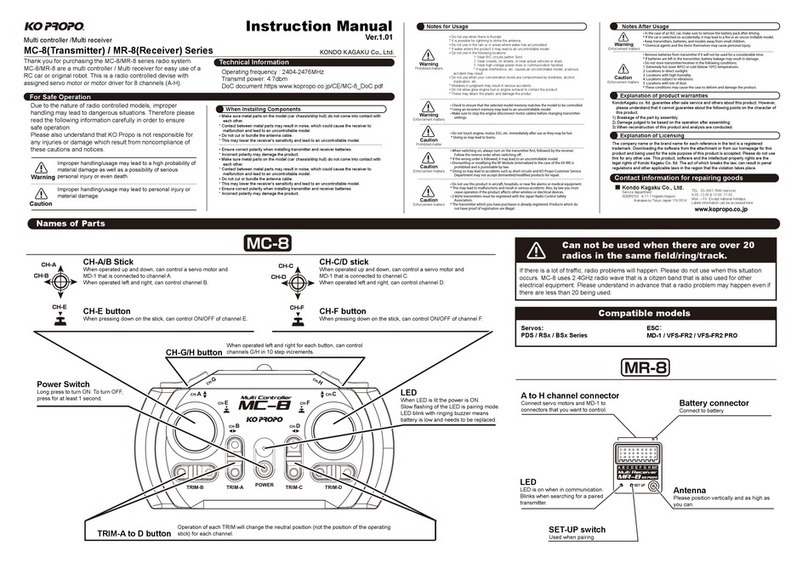

●When switching on, always turn on the transmitter first, followed by the receiver.

Follow the reverse order when switching off.

※If the wrong order is followed, it may lead to an uncontrollable model.

●Dismantling or modifying the RF Module (internalized in the case of the EX-1) is

prohibited and is punishable by law.

※Doing so may lead to accidents such as short circuits and KO Propo Customer

Service Department may not accept dismantled/modified products for repair.

●Do not use this product in aircraft, hospitals, or near fire alarms or medical equipment.

※This may lead to malfunctions and result in serious accidents. Also, by law you must

cease operation if the product affects other wireless or electrical devices.

●2.4GHz transmitters must be registered with the Japan Radio Control Safety

Association.

※The transmitter which you have purchases is already registered. Products which do

not have proof of registration are illegal.

●In the case of an R/C car, make sure to remove the battery pack after driving.

※If the car is switched on accidentally, it may lead to a fire or an uncontrollable model.

●Keep transmitters, batteries, and models away from small children.

※Chemical agents and the items themselves may cause personal injury.

●Remove batteries from transmitter if it will not be used for a considerable time.

※If batteries are left in the transmitter, battery leakage may result in damage.

●Do not store transmitter/receiver in the following conditions:

1. Extremely hot (over 40ºC) or cold (below 10ºC) temperatures.

2. Locations in direct sunlight.

3. Locations with high humidity.

4. Locations subject to vibrations.

5. Locations with lots of dust.

※These conditions may cause the case to deform and damage the product.

●Never short-circuit the battery connector.

※This may lead to a fire or explosion.

●Do not dispose batteries in fires.

※This is very dangerous and may lead to an explosion.

●Use KO Propo chargers to charge the battery and use the correct current (under 1A).

※Incorrect current may lead to battery damage, overheating, or leakage.

※Other manufacturer's chargers may not have a automatic cutoff function.

●Do not subject the battery to strong shocks.

※This may damage the battery and cause leakage or a short circuit.

●Do not dismantle or modify the battery.

※This may cause dangerous leakage of battery fluids.

●Keep away from water. Do not charge a wet battery.

※This may cause overheating and damage.

●Do not charge alkaline batteries.

※Alkaline and other single-use batteries cannot be recharged. Doing so may lead to fire

and damage.

●Do not use wet hands when plugging in the charger's AC Adapter.

※This may result in electrical shocks.

※If there is battery fluid leakage, avoid contact with eyes as it may result in blindness. If contact

with eyes occur, flush with large amounts of water and seek medical attention immediately.

※When disposing batteries, Ni-Cd, Ni-MH, Li-Po, and Li-Fe batteries should be recycled in order to

help protect the environment.

Warning!

Enforcement matters

Prohibited matters

4