●❶

Handling Instructions and Precautions

Specifications Electrical Specifications

Mass

Rated voltage

Item 24 VDC

Applicable voltage range V 21.6 to 26.4 (24±10%)

Current (when rated voltage applied)

mA 23

Power consumption W 0.55

Allowable circuit leakage current

mA 1.0

Type of insulation B type

Insulation resistance Note MΩ 100 or over

Color of LED indicator Red

Surge protection (standard equipment)

Flywheel diode

Note: Value at 500 VDC Megger

Remark: Specication values are based on Koganei test standards.

Notes 1: The effective cross section values are calculated values, and are not measured values.

2: The valve when air pressure is 0.5 MPa [73 psi].

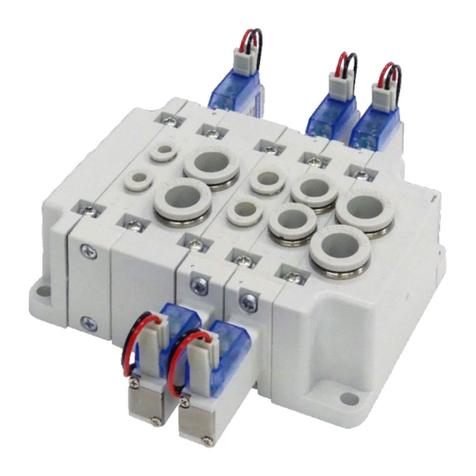

Item Model IBZR8-4E1 IBZR8-4E2

Number of positions 2 positions

Number of ports 5

Valve function Single solenoid Double solenoid

Medium Air

Operation system Internal pilot type

Flow rate

characteristics

Sonic conductance C dm

3

/(s·bar)

mm J42:0.8、J62:1.6、J82:2

in J5/32:0.8、J1/4:1.6、J5/16:2

Effective cross section area [Cv value] Note 1 mm2[Cv]

m m J 4 2:4〔 0 . 2 2 〕、J 6 2:8〔 0 . 4 4〕、J 8 2:10〔 0 . 5 6 〕

in

J

5

/

32

:

4

〔

0.22

〕、J

1/4

:

8

〔

0.44

〕、J5/16:10〔0.56〕

Connection port size

Supply port φ10 [0.394], outlet port φ4 [0.157], φ6 [0.236], φ8 [0.315]

Supply port 3/8、

outlet port 5/32、1/4、5/16

Lubrication Not required

Operating pressure range MPa [psi] 0.2 to 0.7 [29 to 102]

Proof pressure MPa [psi] 1.05 [152]

Operating temperature range (atmospheric and medium) ℃ [℉]

5 to 50 [41 to 122]

Response time Note 2 on/off time ms 15/30 or less 30 or less

Maximum operating frequency Hz 5

Shock resistance m/s2[G] 294.2 [30]

Mounting direction Unrestricted

Model Mass

IBZR8-4E1

J42: 59 [2.08], J62: 60 [2.12], J82: 63 [2.22]

J5/32

:5 9 [2.08]、

J1/4

:6 0 [2.12]、

J5/16

:6 3 [2.22]

IBZR8-4E2

J42: 75 [2.65], J62: 75 [2.65], J82: 78 [2.75]

J5/32

:7 5 [2.65]、

J1/4

:7 5 [2.65]、

J5/16

:7 8 [2.75]

IBZR8Z-E (end block) 81 [2.86]

IBZR8Z-E3/8 81 [2.86]

g [oz]

●24 VDC

Internal circuit

1. Do not apply megger between the pins.

2. Malfunctions, such as the solenoid valve not returning to normal, may occur

if there is a leakage current within the circuit. Always use it at less than the

allowable leakage current shown in the solenoid specifications. If circuit

conditions, etc. cause the leakage current to exceed the maximum

allowable leakage current, consult us.

3. For the double solenoid configuration, avoid energizing both solenoids

simultaneously.

NOTE

NOTE

NOTE

Solenoid with LED indicator and surge suppression

(-)

(+)

Red

Lead wire

Black

(Red)

Attaching and removing plug connector

Use fingers to insert the connector into the pin, push it in until the lever claw

latches onto the protruded section of the connector housing, and complete the

connection.

To remove the connector, squeeze the lever along with the connector, lift the

lever claw up from the protruded section of the connector housing, and pull it out.

Crimping of connecting lead wire and contact

To crimp lead wires into contacts, strip off 4 mm [0.16 in] of the insulation from

the end of the lead wire, insert it into the contact, and crimp it. Be sure at this

time to avoid catching the insulation on the exposed wire crimping section.

Attaching and removing contact and connector

Insert the contact with lead wire into a plug connector □hole until the

contact hook latches on and is secured to the plug connector. Confirm

that the lead wire cannot be easily pulled out.

To remove it, insert a tool with a fine tip (such as a small screwdriver)

into the rectangular hole on the side of the plug connector to push up

on the hook, and then pull out the lead wire.

1. Do not pull hard on the lead wire. It could result in defective contacts,

breaking wires, etc.

2. If the pin is bent, use a small screwdriver, etc. to gently straighten out the

pin, and then complete the connection to the plug connector.

1.

Do not pull hard on the lead wire.

2.

Always use a dedicated tool for crimping of connecting lead wire and contact.

Contact: Model 702062-2M

Manufactured by Sumiko Tech, Inc.

Crimping tool: Model F1-702062

Manufactured by Sumiko Tech, Inc.

Protrusion

Pin

Housing

Lever

Connector

Indication of

polarity(DC)

Contact

Connector assembly

Hook Exposed wire

crimping section

Insulation crimp tab

Insulation (Maximum outer diameter: φ1.7 [0.067])

Lead wire

Equivalent to AWG#22〜#28

Exposed wire 4 mm [0.16 in]

Contact

To operate the manual override, press it all the way down.

For the single solenoid, the valve works the same as when in the energized

state as long as the manual override is pushed down, and returns to the rest

position upon release.

For the double solenoid, pressing the manual override on the 14 (SA) side

switches the 14 (SA) to the energized state, and the unit remains in that state

even after the manual override is released. To return it to the rest position,

operate the manual override on the 12 (SB) side. This is the same for the

solenoid 12 (SB).

PUSH

NOTE

1. The iB-ZERO series uses pilot type solenoid valves, so if you do not

supply air to the 1 (P) port, the main valve will not change, even if

you operate the manual override.

2. Do not attempt to operate the manual override with a pin or other

object having an extremely fine tip. It could result in damage to the

manual override.

Manual override

mm

in

mm

in

mm

in

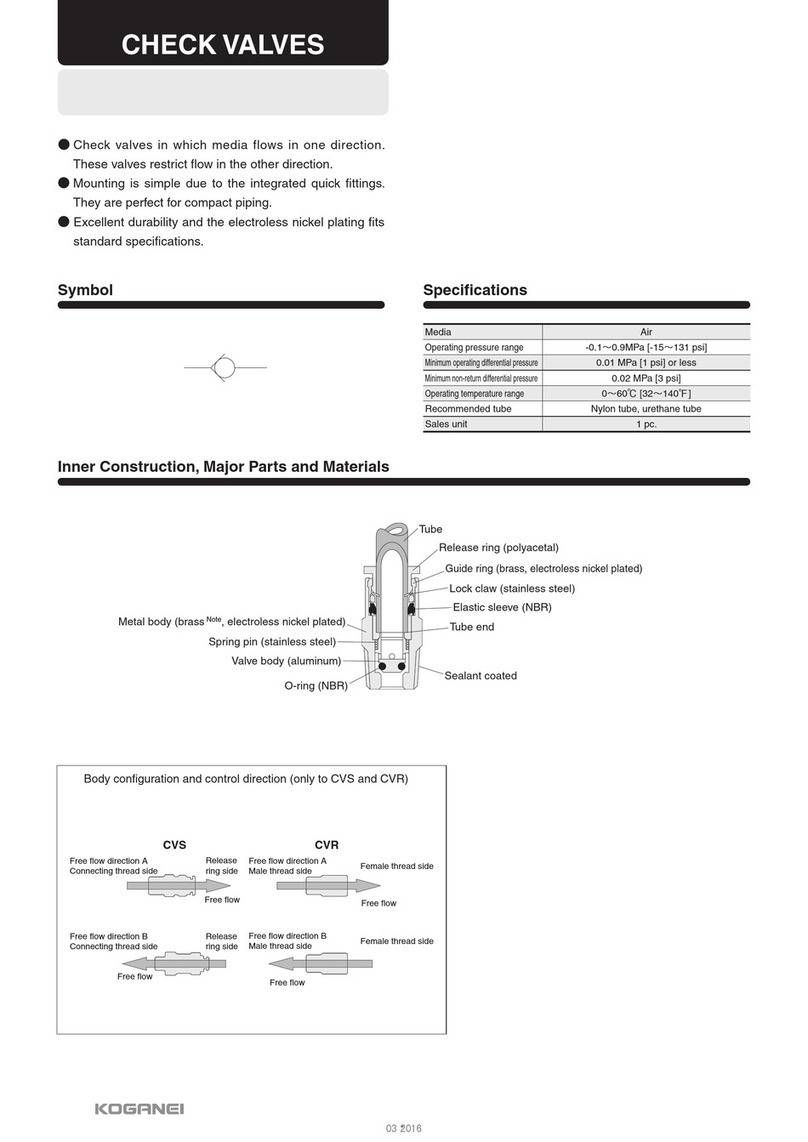

Identification of quick fitting size

Tube size unit Release ring color

mm size Ivory

in size Milk white