Handling Instructions and Precautions

Solenoid

●DC12V, DC24V

Standard solenoid (Surge suppression)

Solenoid with LED indicator

(Surge suppression)

Order code:-PSL, -PLL

●AC100V, AC200V

Standard solenoid (Surge suppression)

Solenoid with LED indicator

(Surge suppression)

Order code:-PSL, -PLL

Plug connector

Use fingers to insert the connector into the

pin, push it in until the lever claw latches

onto the protruded section of the connector

housing, and complete the connection.

To remove the connector, squeeze the lever

along with the connector, lift the lever claw

up from the protruded section of the

connector housing, and pull it out.

To crimp lead wires into contacts, strip off

4mm [0.16in.] of the insulation from the end

of the lead wire, insert it into the contact,

and crimp it. Be sure to avoid catching the

insulation on the exposed wire crimping

section.

Insert the contact with a lead wire into a plug

connector □hole until the contact hook

latches on the connector and is secured to

the plug connector. Confirm that the lead

wire cannot be easily pulled out.

To remove it, insert a tool with a fine tip (such

as a small screwdriver) into the rectangular

hole on the side of the plug connector to

push up on the hook, and then pull out the

lead wire.

Common terminal pre-wired

plug connector

1. Pre-wired common terminal at DC

positive side or AC.

Order code

With straight connector: -CPSL

With L connector: -CPLL

2. Pre-wired common terminal at DC

negative side

Order code

With straight connector: -CMSL

With L connector: -CMLL

C

Protruded section

Pin

Lever

Connector housing

Connector

Indication

of polarity

(DC)

Contact

Connector

assembly

Hock Exposed wire

crimping section

Insulation crimp tab

Insulation(Maximum

outer diameterφ1.7)

Lead wire

Equivalent to

AWG22〜26

Exposed wire 4mm

Contact

※Illustration shows the 110 series.

(−)(−)(−)

(−)

(−)

(−) COM

(

+

)

ColorofCOM, crossover wire

DC12V: Brown

DC24V: Red

AC100V: Yellow

AC200V: White

Polarity is for DC.

Crossover wire

Connector

Connector housing

(+)(+)(+)

(+)(+)

(+) COM

(

−

)

Crossover wire

Connector

Connector housing

ColorofCOM, crossover wire

DC12V: Black

DC24V: Black

w and eare for with DIN connector (Order code : -39).

w and eare for with DIN connector (Order code : -39).

(+)

(−)

w

e

Short circuit protection diode

Solenoid

Flywheel diode

Lead wire: DC12V: Brown

Lead wire: Black

DC24V: Red

(+)

(−)

LED indicator: Red

Lead wire: Black

Lead wire: DC12V: Brown

LED indicator

(Light Emitting Diode)

DC24V: Red

Solenoid

Lead wire: AC100V: Yellow

Varistor

orwe

ew

or

AC200V: White

Lead wire:

AC100V: Yellow

AC200V: White

AC100V: Yellow

AC200V: Green

LED indicator

(Light Emitting Diode)

Diode

LED indicator:

Internal circuit

Cautions: 1. Do not apply megger between the

lead wires.

2. The DC solenoid will not short

circuit even if the wrong polarity is

applied, but the valve will not

operate.

3. Leakage current inside the circuit

could result in failure of the

solenoid valve to return, or in other

erratic operation. Always use it

within the range of the allowable

leakage current. If circuit condi-

tions, etc. cause the leakage

current to exceed the allowable

leakage current, consult us.

4. For double solenoid and twin

solenoid, avoid energizing both

solenoids simultaneously. The

valve could fall into a neutral

position.

Attaching and removing plug connector

Crimping of connecting lead wire and contact

Cautions: 1.

Do not pull hard on the lead wire.

2.

Always use a dedicated tool for crimping of

connecting lead wire and contact.

Contact: Model 702062-2M

Manufactured by Sumiko Tech, Inc.

Crimping tool: Model F1-702062

Manufactured by Sumiko Tech, Inc.

Attaching and removing contact and connector

Cautions: 1. Do not pull hard on the lead wire.It

could result in defective contacts,

breaking wires, etc.

2. If the pin is bent, use a small

screwdriver, etc. to gently

straighten out the pin, and then

complete the connection to the

plug connector.

Cautions: 1. The diagrams show the straight

connector configuration.

While the connector’s orientation is

different in the case of the L

connector, in every case the first

COM lead wire comes from the last

station’s mounted valve.

2. Since the COM terminal is connected

to a crossover terminal inside the

connector housing, the connector

cannot be switched between a

positive common and a negative

common by changing the connectors.

●DC24V

Tandem solenoid

Manual override

To operate the manual override, press it all the way

down. The single solenoid valve works the same as

when in the energized state as long as the manual

override is pushed down, and returns to the normal

position upon release.

For the double solenoid and twin solenoid valves,

pressing the manual override on the 12(S1) side

switches the 12(S1) to enter the energized position,

and the unit remains in that state even after the

manual override is released. To return it to the

normal position, operate the manual override on the

14(S2) side. This is the same for the solenoid

14(S2).

※Illustration shows the 110 series.

Use a small screwdriver to turn the adjusting

knob several times in the clockwise direction,

and lock the manual override in place. When

locked, turning the adjusting knob several times

in the counterclockwise direction releases a

spring on the manual override, returns it to the

normal position, and releases the lock.

For the locking protruding type, when the

adjusting knob is not turned, this type acts just

like the non-locking type, like the valve is the

energized position as long as the manual

override is pushed down, and it returns to the

normal position upon release.

※Illustration shows the 110 series.

Manual override (Tandem solenoid)

To lock the locking type manual override, use a

small screwdriver to push down the manual

override in all the way, then set the 0 position as

the reference point and turn it in the clockwise

direction as far as position A. This achieves the

same conditions as when the 14(SA) side is

energized, and the manual override is locked in

place. For the 12(SB) side, turn it in the

counterclockwise direction as far as position B.

To release the lock, return the manual override

to the 0 position. A spring mechanism returns the

manual override to its normal position, and the

lock is released. Care should be taken to avoid

excessive turning of the manual override, which

could damage it.

To lock the locking protruding type manual override

or locking manual lever type, use either a small

screwdriver or your fingertips to push the manual

override button (manual lever) all the way down, then

set the 0 position as the reference point and turn it in

the clockwise direction as far as position A. This

achieves the same conditions as when the 14(SA)

side is energized, and the manual override button

(manual lever) is locked in place. For the 12(SB)

side, turn it in the counterclockwise direction as far

as position B. To release the lock, return the manual

override button (manual lever) to the 0 position. A

spring mechanism returns the manual override

button (manual lever) to its normal position, and the

lock is released. Care should be taken to avoid

excessive turning of the manual override button

(manual lever), which could damage it.

B

A

Locking protruding type manual override

Locking manual lever type

PUSH

PUSH

Locking typeNon-locking type

Locking protruding type, locking manual lever type

Locking protruding type

Cautions: 1.

The 110 series valves are internal pilot

type solenoid valves. As a result, the

manual override cannot switch the main

valve without air supplied from the 1(P)

port.

2.

Always release the lock of the locking type

and locking protruding type manual override

before commencing normal operation.

3. Do not attempt to operate the manual

override with a pin or other object

having an extremely fine tip. It could

damage the manual override button.

4. Do not turn the adjusting knob more

than needed. It could result in

defective operation.

Mounting base 110-21

When installing a mounting base to the valve,

always use the provided screws. The recom-

mended tightening torque for the screws is

49N・cm {5kgf・cm} [4.3in・lbf].

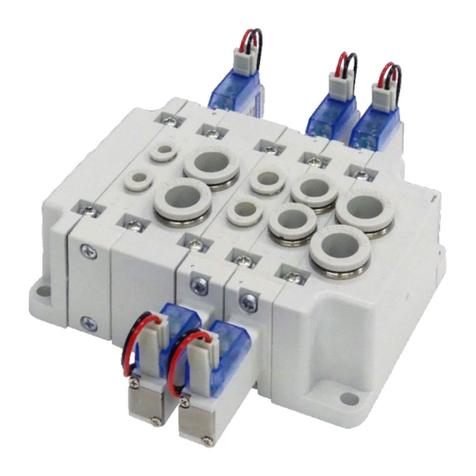

Mounting valves on manifold

When mounting valves on manifold,

apply the recommended tightening torque of

39.2N・cm {4kgf・cm} [3.5in・lbf] for the valve

mounting screws.

Cautions: 1.

The 110 series valves are internal pilot

type solenoid valves. As a result, the

manual override cannot switch the main

valve without air supplied from the 1(P)

port.

2. Always release the lock of the

locking protruding type manual

override before commencing normal

operation.

3. Do not attempt to operate the manual

override with a pin or other object

having an extremely fine tip. It could

damage the manual override button.

4. Do not turn the adjusting knob more

than needed. It could result in

defective operation.

Mounting base 180-21

When mounting valves on manifold,

apply the recommended tightening torque of

49N・cm{5kgf・cm}[ 4.3in・lbf]for the valve

mounting screws.

The 180 series valves are internal pilot

The 180 series valves are internal pilot