12

●

Always observe the following items.

1.

When using this product in pneumatic systems, always use

genuine Koganei parts or compatible parts (recommended parts).

When conducting maintenance and repairs, always use genuine

Koganei parts or equivalent parts (recommended parts).

Always observe the prescribed methods and procedures.

2.

Never attempt inappropriate disassembly or assembly of the

product relating to basic configurations, or its performance or

functions.

Koganei shall not be held responsible for any problems that occur as a

result of these items not being properly observed.

●

When considering the possibility of using this product in situations or

environments not specifically noted in the catalog or instruction

manual, or in applications where safety is an important requirement

such as in aircraft eguipment, combustion equipment, leisure

equipment, safety equipment, and other places where human life or

assets may be greatly affected, take adequate safety precautions

such as allowing plenty of margin for ratings and performance, or fail-

safe measures. Contact the sales department at Koganei regarding

use in such applications.

●

When handling the product, wear protective gloves, safety glasses,

safety shoes, and other protective clothing.

●

When the product can no longer be used, or is no longer necessary,

dispose of it appropriately, according to the “Law Regarding the

Disposal and Cleaning of Waste” or other local governmental rules

and regulations, as industrial waste.

●

Pneumatic equipment can exhibit degraded performance and function

over its operating life. Always conduct daily inspections of the

pneumatic equipment, and confirm that all requisite system functions

are satisfied, to prevent accidents from happening.

●

Air leakage of the solenoid valves cannot be cut to zero. Take volume and

holding time requirements into consideration when designing pressure

(including vacuum) retention in the pressure vessel, and other factors.

●

Air leakage of the solenoid valves cannot be cut to zero. Take volume and

holding time requirements into consideration when designing pressure

(including vacuum) retention in the pressure vessel, and other factors.

●

For double solenoid type (excluding the Tandem 3-port valve), do not

apply current through both solenoids simultaneously. It is impossible

in such a situation to maintain the correct valve position,and the

equipment may operate in an unintended direction, leading to the

possibility of equipment breakdown or personal injury.

●

For double solenoid types, due to the valve position when newly

purchased, connected equipment may operate in unintentional

directions,and may lead to damage of the machine, or personal

injury, so prepare countermeasures to avoid danger.

●

Do not locate the solenoid valve and the wiring that controls it near

power lines running a large current, powerful magnetic fields, or

where power surges occur. Doing so could cause erratic operation.

●

Solenoid valves generate surge voltage and electromagnetic waves

at the OFF operation, which can interfere with the operation of

nearby equipment. Use a surge protected solenoid or implement

appropriate surge and electromagnetic protection measures for the

electrical circuitry.

●

Do not use the product at the beach, in direct sunlight, near mercury

vapor lamps, or near equipment that generates ozone. Ozone causes

rubber components to deteriorate resulting in reduced performance,

or a limitation or stop of functions.(Excluding items with

measurements against ozone.)

●

Do not use any type of medium that is not specifically stipulated in the

specifications. Using a non-specified medium could lead to short term

loss of function, sudden degradation of performance, and a reduced

operating life.

●

When a solenoid valve is installed within the control panel and when

the energizing time is long, implement heat dissipation measures in

order to keep the temperature around the solenoid within

specifications. Also note that continuous energizing for long periods

will result in heat generation by the coil which can lead to deterioration

of solenoid valve performance and shortening of its service life, and

can adversely affect nearby equipment. Contact Koganei if you need

to continuously energize for long periods or if the energizing time in a

day needs to be longer than the deenergizing time.

●

After completing wiring work, check to make sure that all connections

are correct before turning on power.

●

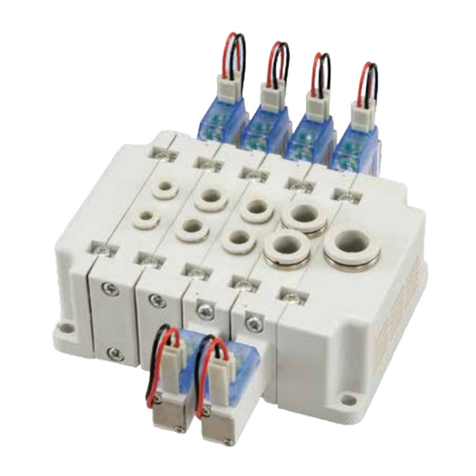

When using the valve in a manifold, be aware when operating an air

cylinder, or performing air blowing operations, back pressure could cause

erratic operations of the cylinder or erroneous air delivery from the air blow

port. Caution is particularly needed when operating single acting cylinders,

or when operating a cylinder and blowing air from the same manifold.

●

Do not use the product in locations subject to direct sunlight

(ultraviolet radiation), high temperatures or high humidity, dust, salt,

or iron powder. Do not expose the product to fluids or an ambient

atmosphere that contains organic solvents, phosphate-based

hydraulic fluid, sulfur dioxide gas, chlorine gas, acids, etc. It could

lead to early shutdown of some functions, a sudden degradation of

performance, and a reduced operating life. For information about

materials, see Materials of major parts.

注 意

●

When mounting the product, leave room for adequate working space

around it. Failure to do so will make it more difficult to conduct daily

inspections or maintenance, which could eventually lead to system

shutdown or damage to the product.

●

Whenever transporting or installing a heavy product, use a lift or

supports to securely support it, and use several people to help lift it

and take other precautions to ensure personal safety.

●

Do not bring any magnetic media or memory media, or other similar

items within one meter of an energized solenoid valve. Doing so creates

the risk of damage to data on the magnetic media due to magnetism.

●

If leakage current is flowing in the control circuit, there is a possibility of

the product performing an unintended operation. Take measures against

current leaking in the control circuit, to ensure that the leakage current

value does not exceed the allowed range in the product specifications.

●Do not use a solenoid valve in locations subject to large electrical currents

or strong magnetic fields. Doing so could result in erratic operation.

●

Oil from a compressor (except from the oil free compressor) can

greatly reduce product performance and can even cause functional

stoppages. Be sure to install a mist filter before pneumatic equipment

to remove oil.

●

The properties of the lubrication oil can change when used in dry air

where dew point temperatures is lower than –20°C [–4°F]. It could

result in degraded performance or in functional shutdown.

●

While the product is in operation, avoid touching it with your hands or

otherwise approaching too close. Heat generated by the coil can

cause burn injury.

Safety precautions

(iB-ZERO)

ATTENTION

Warranty and General Disclaimer

1. Warranty Period

Koganei warrants this product for a period of no more

than 180 days from the date of delivery.

2. Scope of Warranty and General Disclaimer

(1) The Koganei product warranty covers individual

products. When a product purchased from Koganei or

from an authorized Koganei distributor malfunctions

during the warranty period in a way that is attributable to

Koganei's responsibility, Koganei will repair or replace

the product free of charge. Even if a product is still within

the warranty period, its durability is determined by its

operation cycles and other factors. Contact your nearest

Koganei sales office or the Koganei overseas

department for details.

(2) Koganei shall not be held responsible for any losses or

for any damage to other machinery caused by

breakdown, loss of function, or loss of performance of

Koganei products.

(3) Koganei shall not be held responsible for any losses

due to use or storage of the product in a way that is

outside of the product specifications prescribed in

Koganei catalogs and the instruction manual, and/or

due to actions that violate the mounting, installation,

adjustment, maintenance and other safety precautions.

(4) Koganei shall not be held responsible for any losses

caused by breakdown of the product due to factors

outside the responsibility of Koganei, including but not

limited to fire, natural disaster, the actions of third

parties, and intentional actions or errors by you.

Other precautions