The safety precautions for the check valves are shown below. Be sure to read the material in the front of the General Personal Catalog

regarding safety precautions other than those below.

Safety Precautions (Check Valve)

WARNING

●Sometimes the body produces heat when the switch operating frequency of the valve body is extreme. This can cause the risk of

burns due to heat. Contact us if the operating frequencies are extreme.

Handling Instructions and Precautions

Precautions for mounting the body

①Use the appropriate tool to tighten the hex nuts on the fitting.

②Refer to the following table of recommended tightening

torques when attaching the threaded parts. If you use more

than the recommended torque when tightening the threaded

parts, you may cause leaks by fracturing the threads or

deforming the gaskets. Also, if you use less than the

recommended torque when tightening the threaded parts, it

may result in looseness or leaks.

Precautions for disconnecting fittings

Tightening threaded parts

①Use the appropriate tool to remove the hex nuts from the

fitting.

②Remove the sealant from the threads on the other parts. If

the sealant is stuck to the other parts, it may get into

peripheral devices and cause a malfunction.

Metric thread

Tapered threads

for pipes

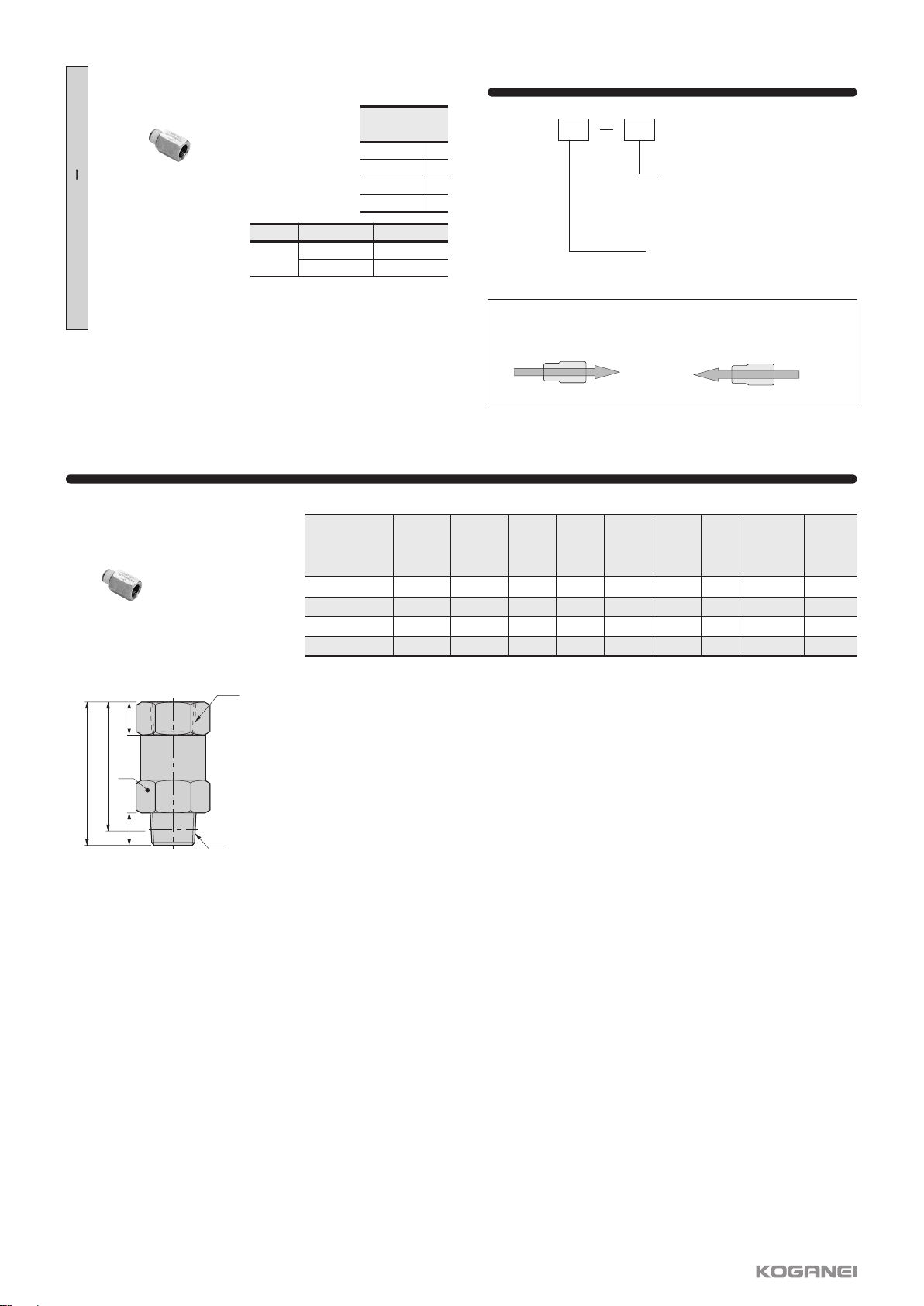

Thread type Thread size

1.5 to 1.9 N•m [13.277 to 16.817 in•lbf]

2 to 2.7 N•m [17.702 to 23.898 in•lbf]

7 to 9 N•m [61.957 to 79.659 in•lbf]

12 to 14 N•m [106.212 to 123.914 in•lbf]

22 to 24 N•m [194.722 to 212.424 in•lbf]

28 to 30 N•m [247.828 to 265.530 in•lbf]

M5×0.8

M6×1

R1/8

R1/4

R3/8

R1/2

Tightening torque

Recommended tightening torque

Precautions for attaching tubes

●Attaching and detaching tubes

①Confirm that the cut surface of the tube is cut straight across,

that the outer surface of the tube is not damaged, and that

the tube has not become oval shaped.

②When connecting tubes, if you do not insert the tube all the

way to the tube end, it may result in leaks.

③After installing the tube, pull on it to check that it does not

come off.

④

Do not meaninglessly press on the release ring before

attaching a tube. Doing so may cause the tube to become

detached.

Tube end

If removing pipes is difficult because the piping space is very

constricted, consult your nearest Koganei sales office for

specialized tools that are available.

Specialized tools for removing tubes

①Tightening threaded parts

Use a wrench on the hex nut to

tighten the threaded parts.

When tightening hex nuts

How to attach and detach tubes

①Attaching tubes

Check valves are equipped with

lock claws that hold tubes in place

when they have been pushed all

the way to the end, and with an

elastic sleeve for sealing the

periphery around the tubes.

②Removing tubes

When removing a tube, pressing

the release ring opens the lock

claw and the tube can be pulled

out.

Be sure to stop the air before

removing tubes.

d

d

c

Precautions for removing tubes

①Before removing tubing, be sure to confirm that the pressure

inside the tubing is zero.

②Uniformly press the release ring inwards as far as it goes

and then pull out the tubing. If you do not fully press in on

the release ring, the tube may not come out, or the tubing

may become scratched causing debris to be left inside the

fitting.

●Mounting

Depending on the usage conditions, check valves may

produce a droning (vibrating) noise. Consult the nearest

Koganei sales office for countermeasures against the noise.

For φ3 [0.118], φ4 [0.157], and φ6 [0.236] tubes

Order codes: UJ-1

For φ6 [0.236], φ8 [0.315], φ10 [0.394], and φ12 [0.472] tubes

Order codes: UJ-2