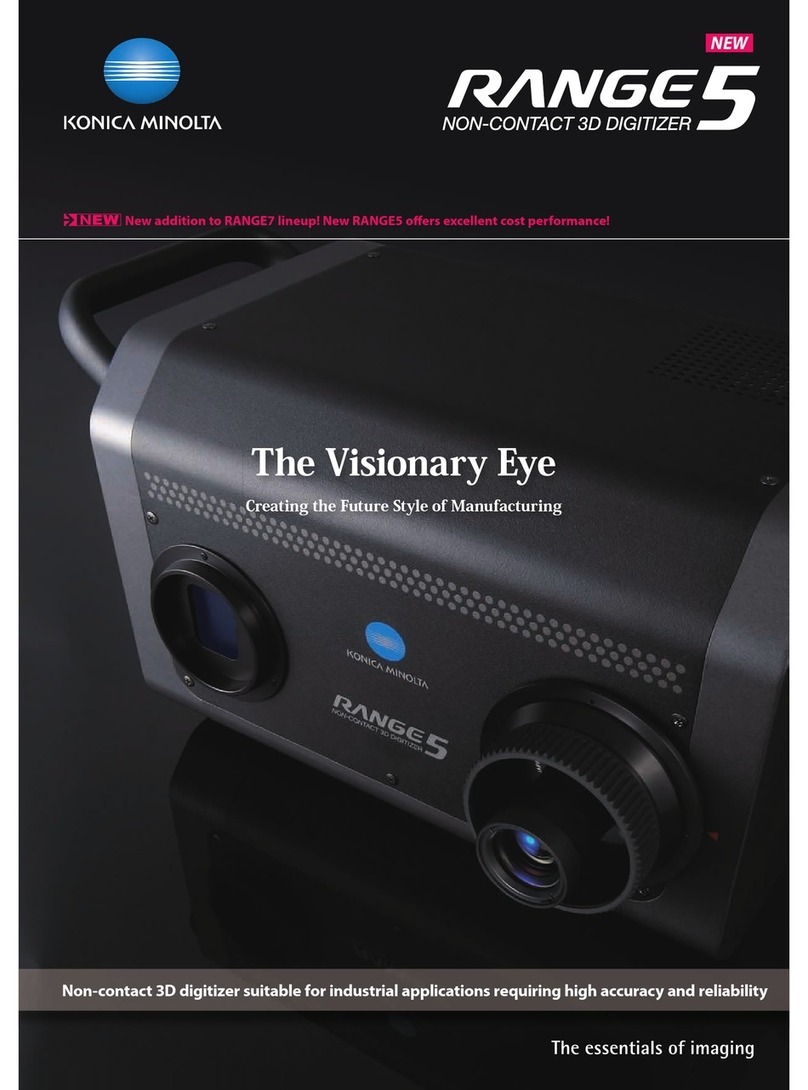

Measurement sample

Viewing

Illumination 2

45º

Illumination 1

Illumination 3

75º

Shade direction

25º

Highlight direction

The CM-512m3 measures colors by illuminating subjects from three

angles simultaneously (25º, 45º and 75º), making it suitable for subjects

such as metallic/pearl coatings used for automotive exteriors or for the

textured materials used for automotive interiors and allowing the

changes in color according to the illumination angle to be measured.

Unlike conventional spectrophotometers, correlation of the measurement

results with visual evaluation of such subjects can be achieved.

The ring-shaped illumination ensures stable

measurement without being affected by the ori-

entation (rotational deviation) of the instrument.

Measurement is stable even for curved sur-

faces, such as automotive components.

Not only flat surfaces but also curved surfaces can be

measured stably with the large measurement area, the

two extension feet and the optional grip attached to the

instrument.

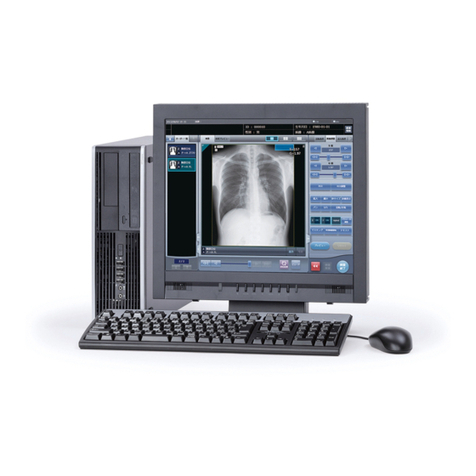

The graph display function enables easy

color judgment even on production sites

without using a personal computer.

Tolerance (allowable range) can be set for each target

data.

Original development

Evaluation equation suitable for measure-

ments of metallic/pearl coating correlates

well with visual evaluation.

With the conventional ∆E*ab equation, the values in the

highlight direction (25º) become larger and do not corre-

lated well with the results of visual evaluation. With the

CM-512m3, the ∆E00 (CIEDE2000) equation is used with

parameters fine-tuned based on proprietary knowhow to

provide measurement data for metallic/pearl coatings

which correlate well with visual evaluation.

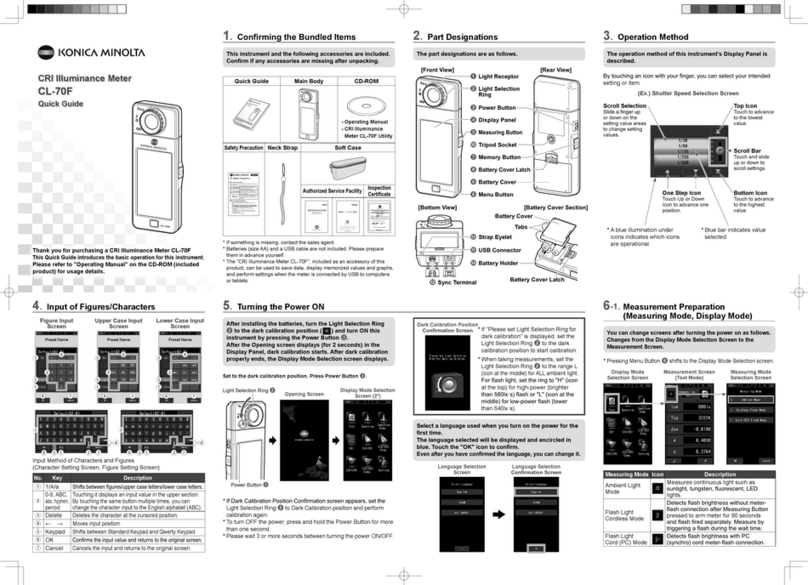

Extension feet

Measurement button

Grip

CM-A42

(optional)

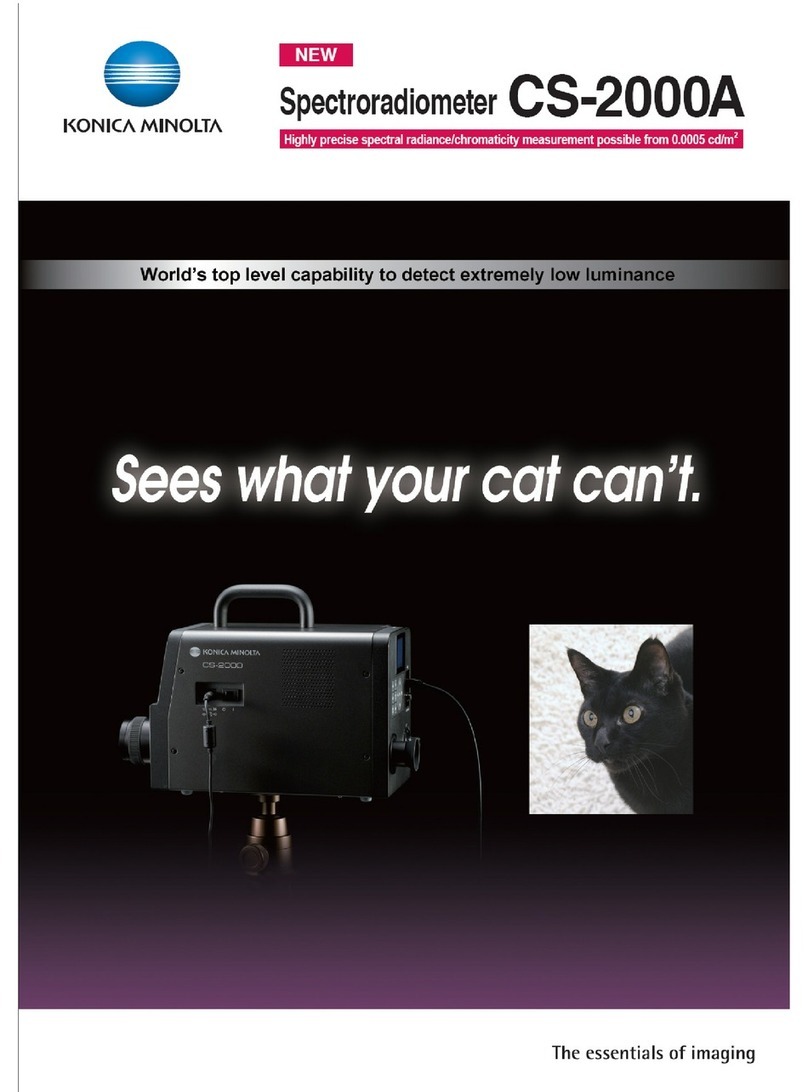

Multi-angle method (Ring illumination from three angles / Light reception in one direction)

Illumination: 25º, 45º, 75º

Light reception: 0º

The measurement sample is illuminated from three angles and the reflection in one direction is received. Metallic/pearl colors may result

in great differences in color appearance depending on the observation angle. Like visual evaluation, the multi-angle method obtains

measured data by applying illumination from three different angles. Consequently, it is suitable for the evaluation of metallic/pearl colors.

Measurement Principle

Illuminating/viewing optical system

Illumination is applied in the form of rings at angles of 25º, 45º and 75º away

from the perpendicular to the sample surface. The light reflected in the direction

perpendicular to the sample surface is received.

25º: Corresponds to the highlight direction of visual evaluation

75º: Corresponds to the shade direction of visual evaluation

Pre-flash function

Pre-flash (at 2% of the intensity of full emission) is performed at the beginning of

measurement to determine the optimal intensity for measurement according to

the reflectance of the sample. This function reduces power consumption and im-

proves repeatability when measuring samples with low reflectance.

Applications for texture measurements

Textured materials used for automotive interiors

With the recently popular textured materials that have large

and deep geometrical patterns, it is difficult to obtain color

differences with integrating sphere (d/0) or 45/0 instruments.

The CM-512m3 allows evaluation that correlates well with visual

evaluation by obtaining data at the angles of 25º and 75º.

Applications for coating measurements

Automotive exterior

The portable, handheld design ensures

easy and stable measurement on

production sites.

The instrument can be held easily

and firmly, and measurements can be

taken without being concerned about

its orientation (rotational deviation).

Personal computers and home appliances

Construction materials such as exterior

walls and kitchen panels

Office furniture

Even curved surfaces of car bodies or bumpers

can be measured stably.

PASS/FAIL displayColor difference display

∆L* ∆C* ∆H* ∆E00

Vertical

full-scale

value

±0 line

25º 45º 75º

∆L*∆C*∆H*∆E00 display example

Line graph display

Color difference tolerance

setting example: ∆E00=0.5