1. PRODUCT SPECIFICATIONSTheory of Operation Ver. 1.0 Jan. 2010

2

OUTLINE DF-619

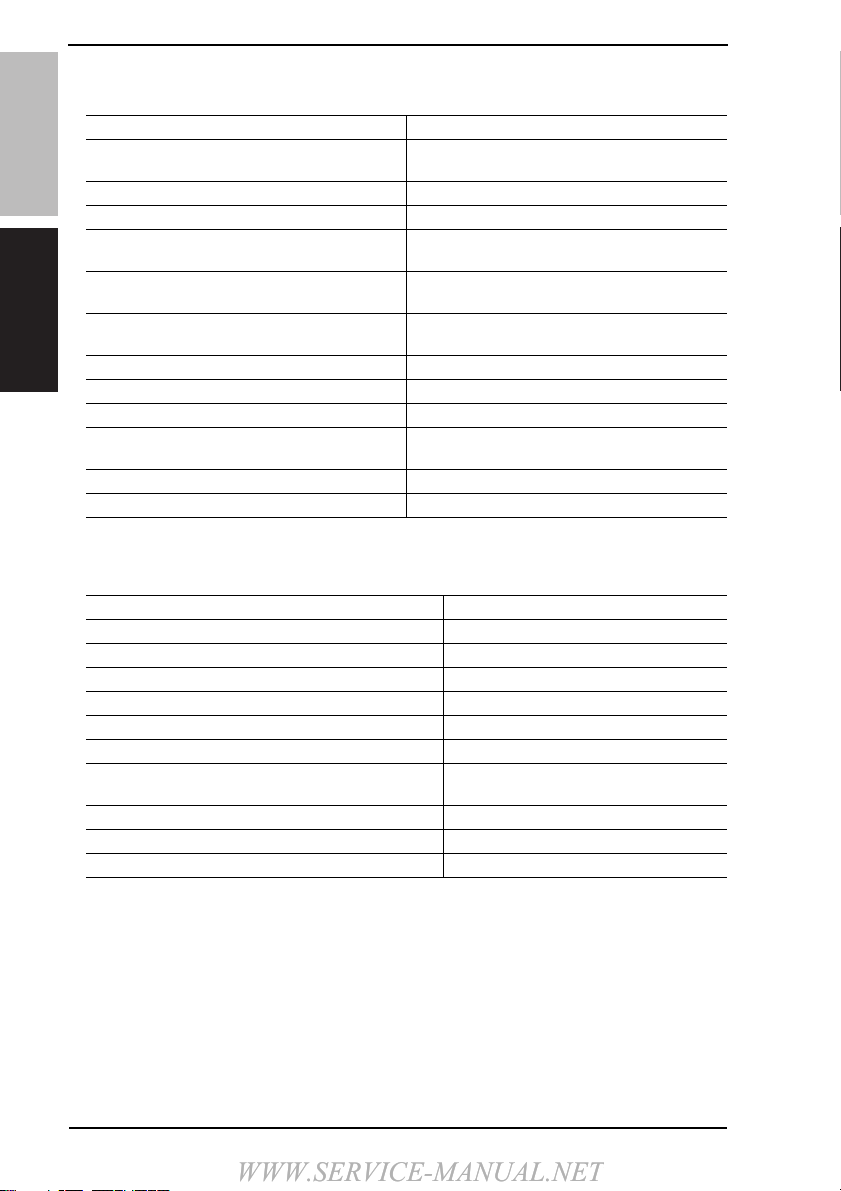

D. Paper feed prohibited originals

• If fed, trouble occurrence will be highly possible.

E. Paper feed not guaranteed originals

• If fed, paper feed will be possible to some extent but trouble occurrence will be possible.

Type of originalPossible trouble

Sheetsstapled or clipped together Paper feed failure, damaged sheet, defective drive

mechanism due to jammed staplesor clips

Sheetsglued together Paper feed failure, damaged sheet

Book originalPaper feed failure, damaged sheet

Original weighing less than 35 g/m2(9.25 lb) or

210 g/m2(55.75 lb) or more Paper feed failure, transport failure

Sheetsfolded, torn or wrinkled Paper feed failure, damaged sheet,

transport failure

Sheetsseverely curled Sheetsmisfed due to being dog-eared or fed in

askew

OHP film (Transparency film) Paper feed failure, transport failure

Label paper Paper feed failure, transport failure

Offset master paper Paper feed failure, transport failure

Glossy photographic paper or glossy enamel

paper Transport failure, damaged sheet

Sheetsclipped or notched Damaged sheet, transport failure

Sheetspatched Patched part folded or torn sheet

Type of originalPossible trouble

Sheetslightly curled (Curled amount: 10 to 15 mm) Dog-eared, exit failure, transport failure

Heat sensitive paper Edge folded, exit failure, transport failure

Ink jet paper Paper feed failure, transport failure

Sheetswith smooth surface (Coated paper) Paper feed failure, transport failure

Intermediate paper Paper feed failure, transport failure

Paper immediately after paper exit from the main unit Paper feed failure, transport failure

Paper with many punched holes(e.g., loose leaf) limited

to vertical feeding Multi-page feed due to flashesfrom holes

Sheetswith 2 to 4 holesTransport failure

Sheetstwo-folded or Z-folded Transport failure, image deformation

Sheetswith rough surface (e.g., letterhead) Paper feed failure

WWW.SERVICE-MANUAL.NETWWW.SERVICE-MANUAL.NETWWW.SERVICE-MANUAL.NETWWW.SERVICE-MANUAL.NETWWW.SERVICE-MANUAL.NET