Installation and Operating Instructions OPTIMASS 2

Contents

1 MECHANICAL INSTALLATION 6

1.1 General principles 6

1.1.1 Transport and Lifting 8

1.2 OPTIMASS 7000 Single Straight Tube Meter 9

1.2.1 Specific Installation Guidelines 9

1.2.2 Ambient / Process temperatures 9

1.2.3 Pressure Equipment Directive (PED) requirements 9

1.2.4 Secondary Pressure containment 10

1.2.5 Pressure de-rating 10

1.2.6 Hygienic Applications 13

1.2.7 Heating and insulation 14

1.2.8 Purge Port Meters and Burst Disk Meters 18

1.2.9 Technical Data 19

1.2.10 Weights & Dimensions 20

1.3 OPTIMASS 3000 (7100) Single Z Shaped Tube Meter 23

1.3.1 Specific Installation Guidelines 23

1.3.2 Ambient / Process temperatures 24

1.3.3 Pressure Equipment Directive (PED) requirements 24

1.3.4 Secondary Pressure containment 25

1.3.5 Pressure de-rating 25

1.3.6 Heating and insulation 26

1.3.7 Purge Port Meters and Burst Disk Meters 26

1.3.8 Technical Data 27

1.3.9 Weights & Dimensions 28

1.4 OPTIMASS 8000 / 9000 Meter with Twin U Measuring Tubes 30

1.4.1 Specific Installation Guidelines 30

1.4.2 Ambient / Process temperatures 30

1.4.3 Pressure Equipment Directive (PED) requirements 30

1.4.4 Secondary Pressure containment 31

1.4.5 Pressure de-rating 31

1.4.6 Hygienic Applications 33

1.4.7 Heating and insulation 34

1.4.8 Purge Port Meters and Burst Disk Meters 35

1.4.9 Technical Data 35

1.4.10 Weights & Dimensions 35

2 ELECTRICAL INSTALLATION 39

2.1 Location and connecting cables 39

2.2 Connection to power 39

2.2.1 Power Supply Wiring MFC050 39

2.2.2 Power Supply Wiring MFC051 Non Ex 39

2.2.3 Power Supply Wiring MFC 051 Ex 40

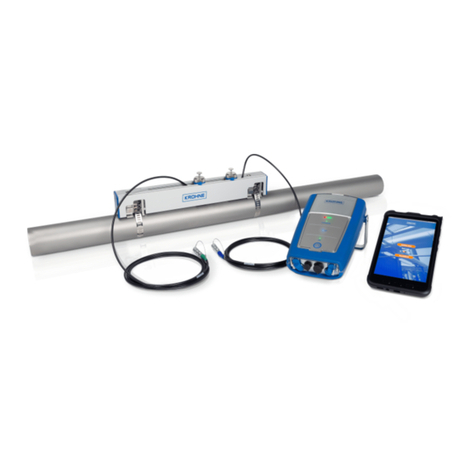

2.3 Connection of remote meters 40

2.4 Hazardous Area requirements 41

2.5 Inputs and outputs 41

2.5.1 Inputs/Outputs MFC 050 41

2.5.2 Inputs / Outputs MFC051 46

2.6 Compact to Remote / Remote to Compact conversion instructions 48

2.7 Technical Data 48

2.7.1 MFC050 48

2.7.2 MFC051 49

3 START-UP 50

3.1 Factory Set Parameters 50

3.2 Initial Start-up 50

3.3 Zero point adjustment 51

3.4 Programming the converter with a bar magnet 51