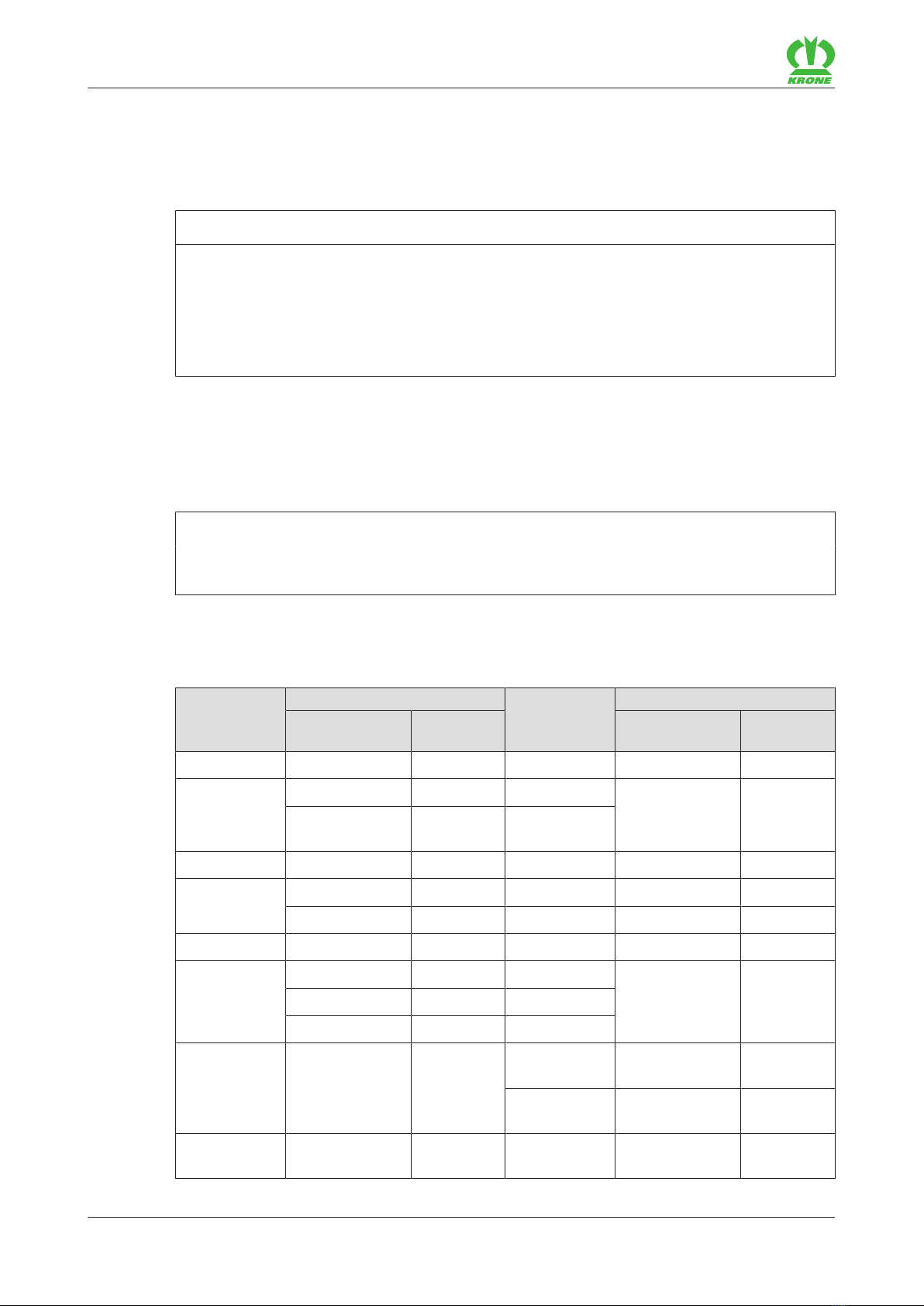

Contents

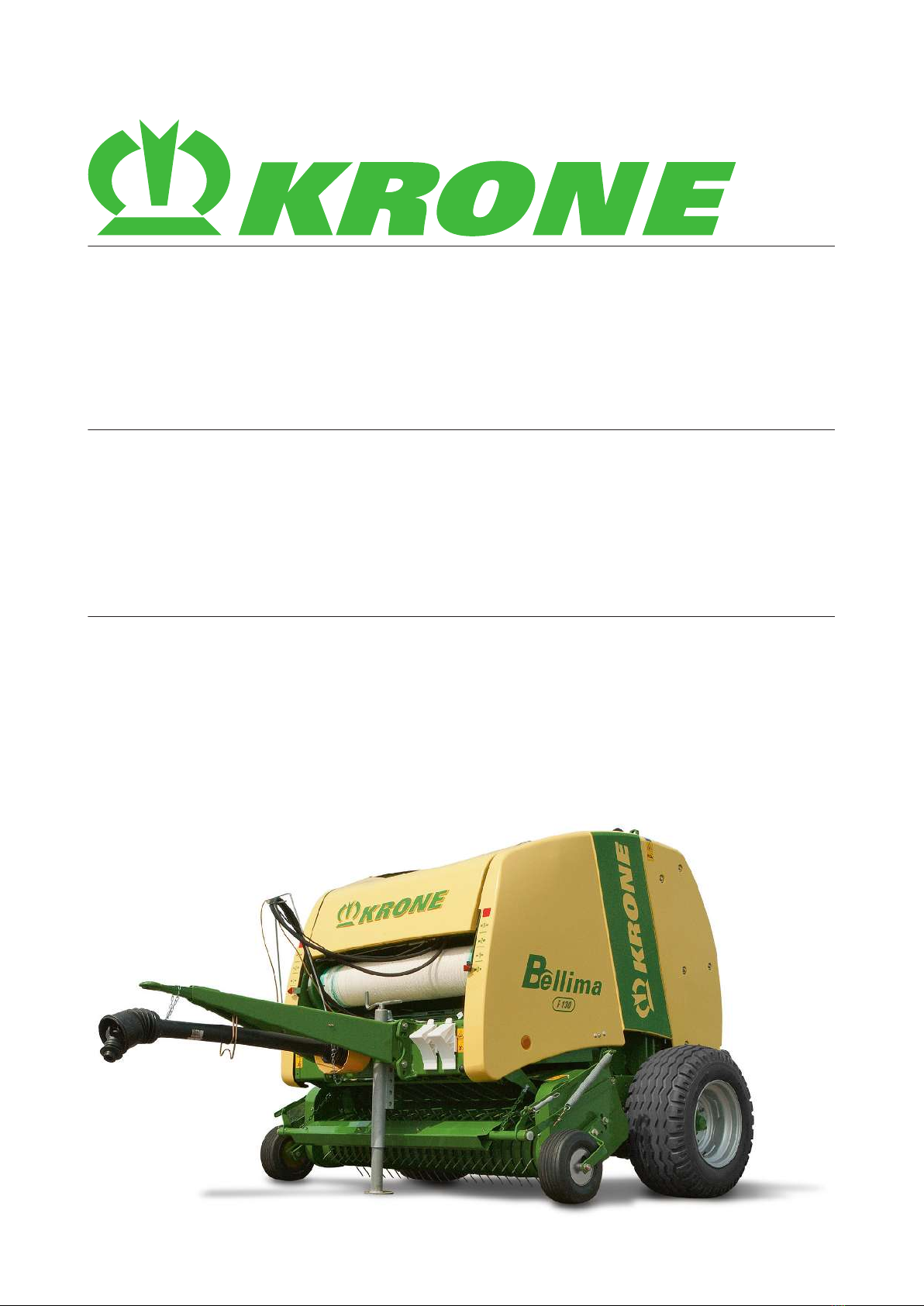

Bellima F 130

Original Operating Instructions 150000148_06_en 5

10.1 Adjusting the guide wheels of the pick-up ................................................................................. 78

10.2 Adjusting the relief springs of the pick-up .................................................................................. 79

10.3 Adjusting the number of twine layers......................................................................................... 79

10.4 Adjusting the twine limiter .......................................................................................................... 80

10.5 Setting the number of net layers................................................................................................ 80

10.6 Setting the baling pressure ........................................................................................................ 81

10.7 Adjusting the sensors of the electronic baling pressure indicator.............................................. 82

10.8 Setting the twine brake .............................................................................................................. 83

10.9 Setting the driver of the twine tying............................................................................................ 83

10.10 Setting the wrapping material brake .......................................................................................... 84

10.11 Setting the hydraulic tying start unit for net and twine tying....................................................... 85

10.12 Setting the bale ejector .............................................................................................................. 86

11 Maintenance ............................................................................................................................. 87

11.1 Maintenance table ..................................................................................................................... 87

11.1.1 Maintenance – prior to the beginning of the season.................................................................. 87

11.1.2 Maintenance – once after 10 hours ........................................................................................... 88

11.1.3 Maintenance – once after 50 hours ........................................................................................... 88

11.1.4 Maintenance – every 10 hours, at least daily ............................................................................ 88

11.1.5 Maintenance – every 50 hours .................................................................................................. 88

11.1.6 Maintenance – every 500 hours ................................................................................................ 88

11.1.7 Maintenance – every 6 years..................................................................................................... 88

11.2 Lubrication Chart ....................................................................................................................... 89

11.3 Lubricating the universal shaft ................................................................................................... 94

11.4 Tightening torques ..................................................................................................................... 94

11.5 Checking/maintaining tyres........................................................................................................ 97

11.6 Servicing the main gearbox ....................................................................................................... 98

11.7 Bleed the friction clutch on the universal shaft .......................................................................... 99

11.8 Checking and adjusting the twine tying unit............................................................................. 100

11.8.1 Cleaning the twine guide slide and oiling the drive chains ...................................................... 100

11.8.2 Checking and adjusting the starter roll and the pressure rolls................................................. 101

11.8.3 Cleaning the cutting unit .......................................................................................................... 101

11.9 Checking and adjusting the net wrapping device .................................................................... 102

11.9.1 Adjusting the friction wheel and drive wheel............................................................................ 102

11.9.2 Setting the spring rail ............................................................................................................... 102

11.9.3 Adjusting the cutting unit.......................................................................................................... 103

11.10 Checking and setting the hydraulic tying start unit .................................................................. 104

11.11 Checking hydraulic hoses........................................................................................................ 104

11.12 Checking and setting the lock hook blocker at the tailgate...................................................... 105

11.13 Checking and setting the transverse worm conveyors of the pick-up...................................... 106

11.14 Set and oil the drive chains...................................................................................................... 106

11.14.1 Drive chain of the pick-up ........................................................................................................ 106

11.14.2 Drive chain of the bale formation conveyor ............................................................................. 108

11.14.3 Drive chain of the rollers .......................................................................................................... 108

11.15 Check the distance of the roller to the bale formation conveyor chain, set if applicable ......... 109

11.16 Cleaning the machine .............................................................................................................. 110

11.17 Clean the bushing and the drawbar eye .................................................................................. 111

11.18 Hydraulic diagram.................................................................................................................... 111

11.19 Circuit diagram of the electronic baling pressure indicator ...................................................... 113

12 Disturbance, cause and remedy........................................................................................... 114

12.1 Disturbances at the pick-up or during picking up of crops ....................................................... 114

12.2 Disturbances at the tying unit or during the tying cycle ........................................................... 115

12.3 Disturbances at the twine tying unit ......................................................................................... 116

12.4 Disturbances during or after the baling process ...................................................................... 117

12.5 Setting the twine guide at the starter roll ................................................................................. 119

12.6 Setting the cutting unit of the twine tying unit .......................................................................... 119

12.7 Checking and adjusting the starter roll and the pressure rolls................................................. 120

12.8 Changing O-ring seal on the twine coil starting device............................................................ 120

12.9 Setting the tailgate lock............................................................................................................ 121

12.10 Setting the mechanical baling pressure indicator .................................................................... 122