Contents

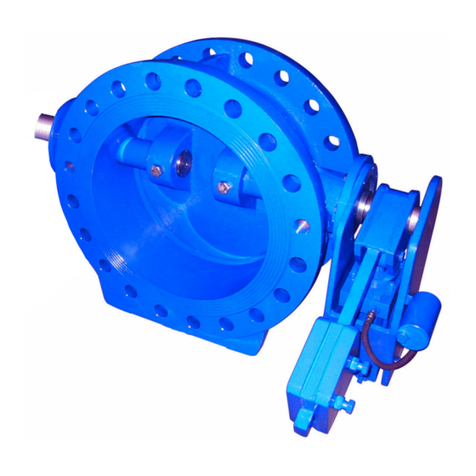

4 of 60 BOAX-B

6 Commissioning/Start-up/Shutdown................................................................................................... 29

6.1 Commissioning................................................................................................................................................29

6.1.1 Prerequisites for commissioning ...................................................................................................... 29

6.1.2 Actuation/operation ......................................................................................................................... 29

6.1.2.1 Actuating element – lever ........................................................................................................29

6.1.2.2 Actuating element – manual gearbox.....................................................................................29

6.1.2.3 Actuating element – electric actuator .....................................................................................30

6.1.2.4 Actuating element – pneumatic actuator ...............................................................................30

6.1.3 Functional test................................................................................................................................... 30

6.2 Operating Limits.............................................................................................................................................30

6.2.1 Ambient temperature....................................................................................................................... 30

6.3 Shutdown........................................................................................................................................................31

6.3.1 Measures to be taken for shutdown................................................................................................ 31

6.3.1.1 Valve with lever ........................................................................................................................31

6.3.1.2 Valve with manual gearbox .....................................................................................................31

6.3.1.3 Valve with electric actuator .....................................................................................................31

6.4 Returning to service .......................................................................................................................................31

7 Servicing/Maintenance........................................................................................................................ 32

7.1 Safety regulations...........................................................................................................................................32

7.2 Servicing/inspection........................................................................................................................................32

7.2.1 Supervision of operation .................................................................................................................. 32

7.2.2 Tools required ................................................................................................................................... 33

7.2.3 Inspection work................................................................................................................................. 33

7.2.3.1 Lubrication ................................................................................................................................33

7.2.4 Dismantling the valve ....................................................................................................................... 33

7.2.4.1 General information/Safety regulations..................................................................................33

7.2.4.2 Preparing the valve...................................................................................................................33

7.2.4.3 Removing the actuator.............................................................................................................34

7.2.4.4 Dismantling the piping.............................................................................................................34

7.2.4.5 Dismantling the valve (DN>200 only) ....................................................................................34

7.2.5 Assembling the valve ........................................................................................................................ 34

7.2.5.1 General information/Safety regulations..................................................................................34

7.2.5.2 Mounting the actuator.............................................................................................................34

7.2.5.3 Connecting the piping..............................................................................................................35

7.2.5.4 Assembling the valve ................................................................................................................35

7.3 Spare parts stock.............................................................................................................................................35

7.3.1 Ordering spare parts......................................................................................................................... 35

8 Trouble-shooting.................................................................................................................................. 37

9 Related Documents.............................................................................................................................. 38

9.1 General assembly drawing with list of components ....................................................................................38

9.2 Dimensions and weights ................................................................................................................................40

9.2.1 Dimensions of BOAX-B ..................................................................................................................... 40

9.2.2 Dimensions and weights of BOAX-B + lever CR+/CM+ ................................................................... 41

9.2.3 Dimensions and weights of BOAX-B + manual gearbox MA+ ....................................................... 41

9.2.4 Dimensions and weights of BOAX-B + MS manual gearbox.......................................................... 42

9.2.5 Dimensions and weights of BOAX-B + MC manual gearbox.......................................................... 43

9.2.6 Dimensions and weights of BOAX-B + ACTAIREVO pneumatic actuator..................................... 45

9.2.7 Dimensions and weights of BOAX-B + DYNACTAIREVO pneumatic actuator ............................. 46

9.2.8 Dimensions and weights of BOAX-B + electric actuator ................................................................ 47

9.3 Flange dimensions..........................................................................................................................................48

10 EU Declaration of Conformity............................................................................................................. 50

10.1 EU Declaration of Conformity in accordance with the European Pressure Equipment Directive for

Butterfly Valves...............................................................................................................................................51

11 UK Declaration of Conformity............................................................................................................. 54

11.1 UK Declaration of Conformity for Butterfly Valves......................................................................................54