1

Contents

1.Safety ....................................................................................................................................... 2

1.1 Safety notes ....................................................................................................................................... 2

1.2 Symbols used in this guide ............................................................................................................ 2

2.Main Features ........................................................................................................................ 3

2.1 Summarization ................................................................................................................................... 3

2.2 Functions and Features .................................................................................................................. 3

3.Installation .............................................................................................................................. 4

3.1 Unpack checking .............................................................................................................................. 4

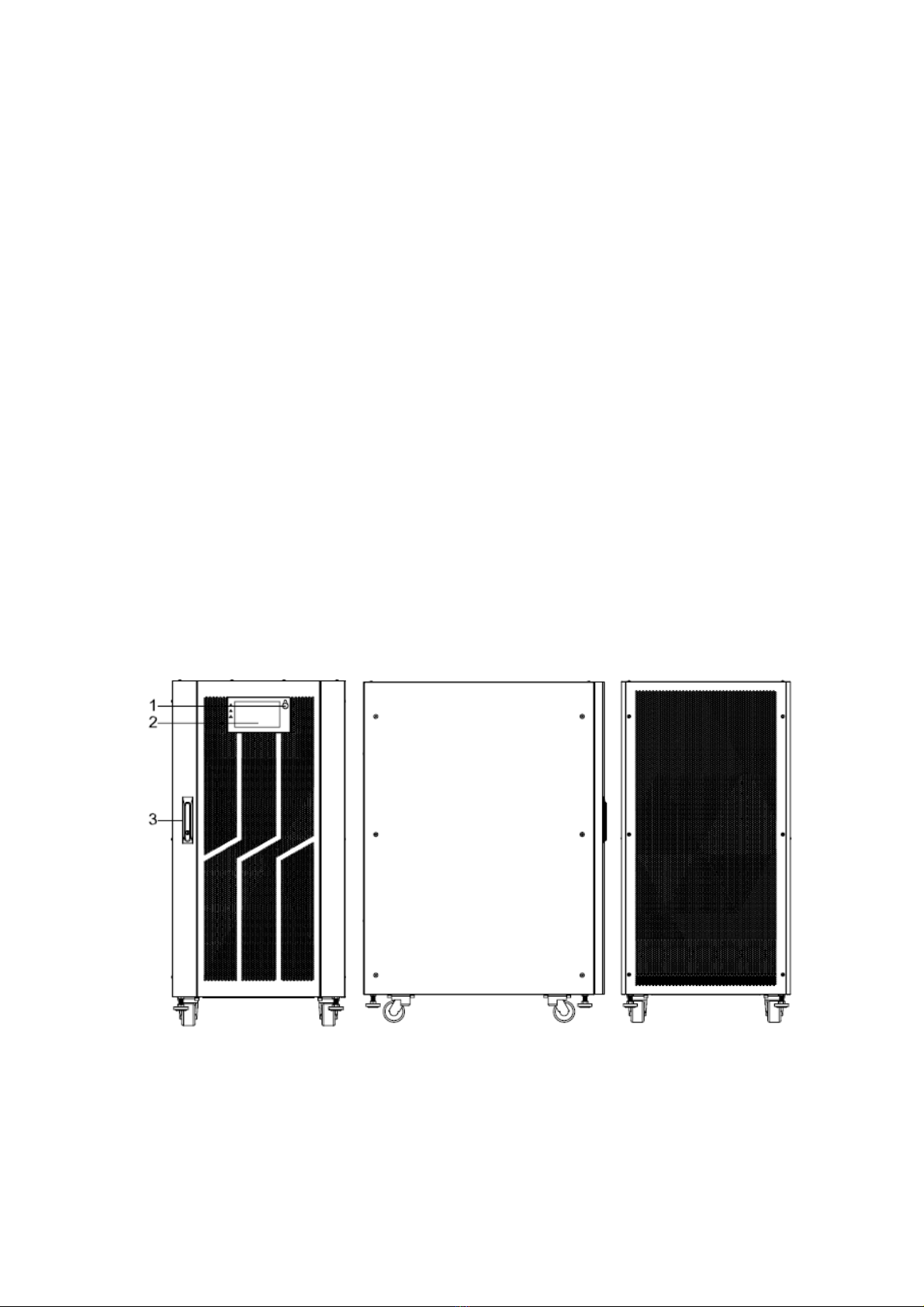

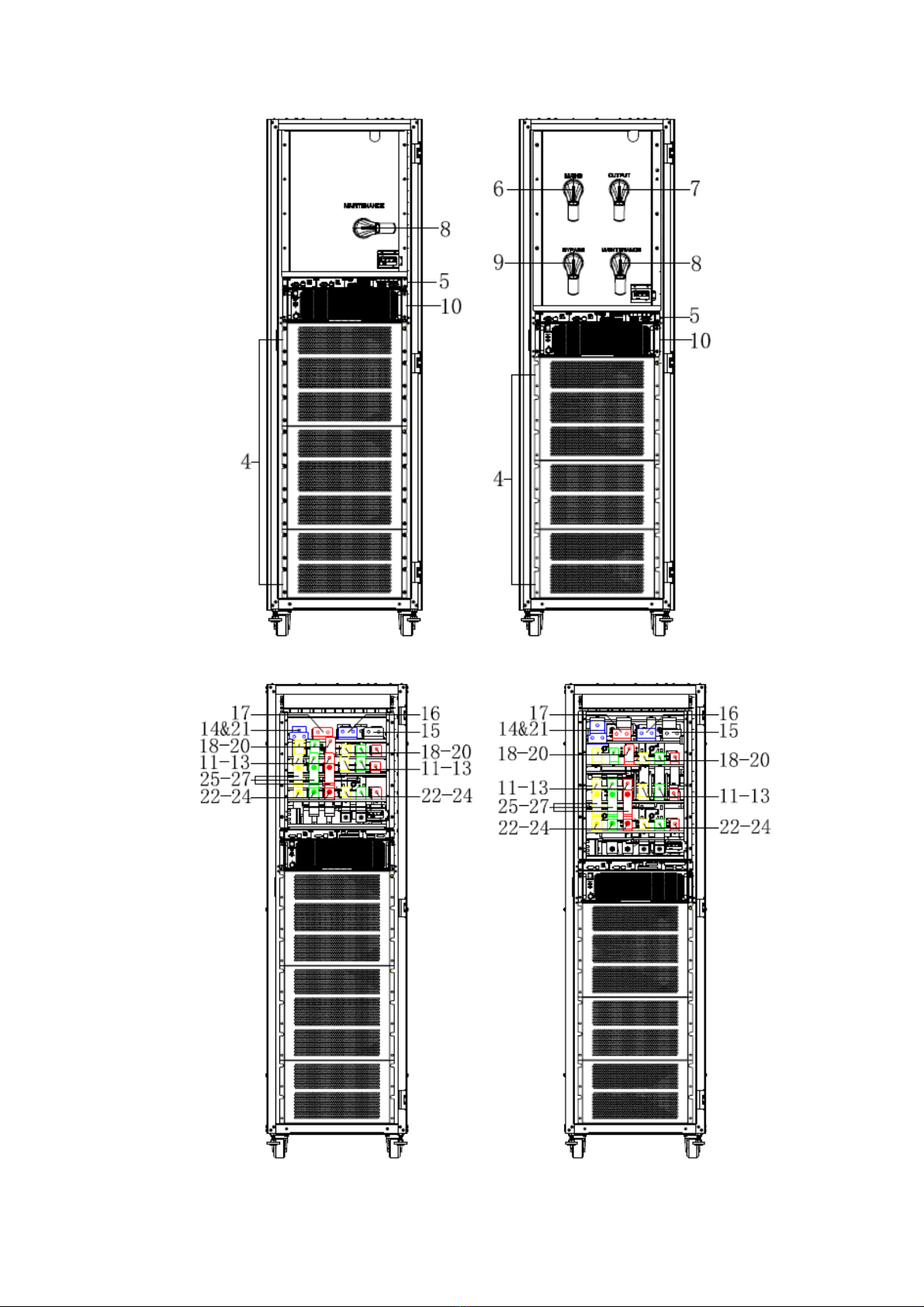

3.2 The appearance of the product ..................................................................................................... 4

3.3 Installation notes ............................................................................................................................ 15

3.4 External Protective Devices .......................................................................................................... 18

3.5 Power Cables ................................................................................................................................... 19

3.6 Power cable connect...................................................................................................................... 23

3.7 Battery connection ......................................................................................................................... 24

3.8 UPS parallel Installation ................................................................................................................ 25

3.8.1 Cabinet installation ............................................................................................................. 26

3.8.2 Parallel cable installation .................................................................................................. 26

3.9 LBS installation (optional) ............................................................................................................ 27

3.9.1 LCD setting ........................................................................................................................... 27

3.9.2 LBS cable installation ......................................................................................................... 27

3.9.3 UPS installation .................................................................................................................... 28

4.Operation .............................................................................................................................. 28

4.1 Operation Modes ............................................................................................................................. 28

4.2 Turn on/off UPS ............................................................................................................................... 31

4.2.1 Restart procedure ................................................................................................................ 31

4.2.2 Test procedure ..................................................................................................................... 31

4.2.3 Cold start procedure ........................................................................................................... 32

4.2.4 MAINTENANCE BYPASS ................................................................................................... 32

4.2.5 Shut down procedure ......................................................................................................... 33

4.2.6 Startup procedure for parallel system ........................................................................... 33

4.3 The Display ....................................................................................................................................... 34

4.4 Display Messages/Troubleshooting ........................................................................................... 64

4.5 Options .............................................................................................................................................. 66

Appendix 1 Specifications ..................................................................................................... 67

Appendix 2 Problems and Solution ..................................................................................... 72

Appendix 3 CAN communication port definition ............................................................. 74

Appendix 4 RS485 communication port definition ......................................................... 75

Appendix 5 COM communication port definition ............................................................ 75

Appendix 6 LBS port definition ............................................................................................ 76

Appendix 7 REPO instruction ............................................................................................... 76