- 9 -

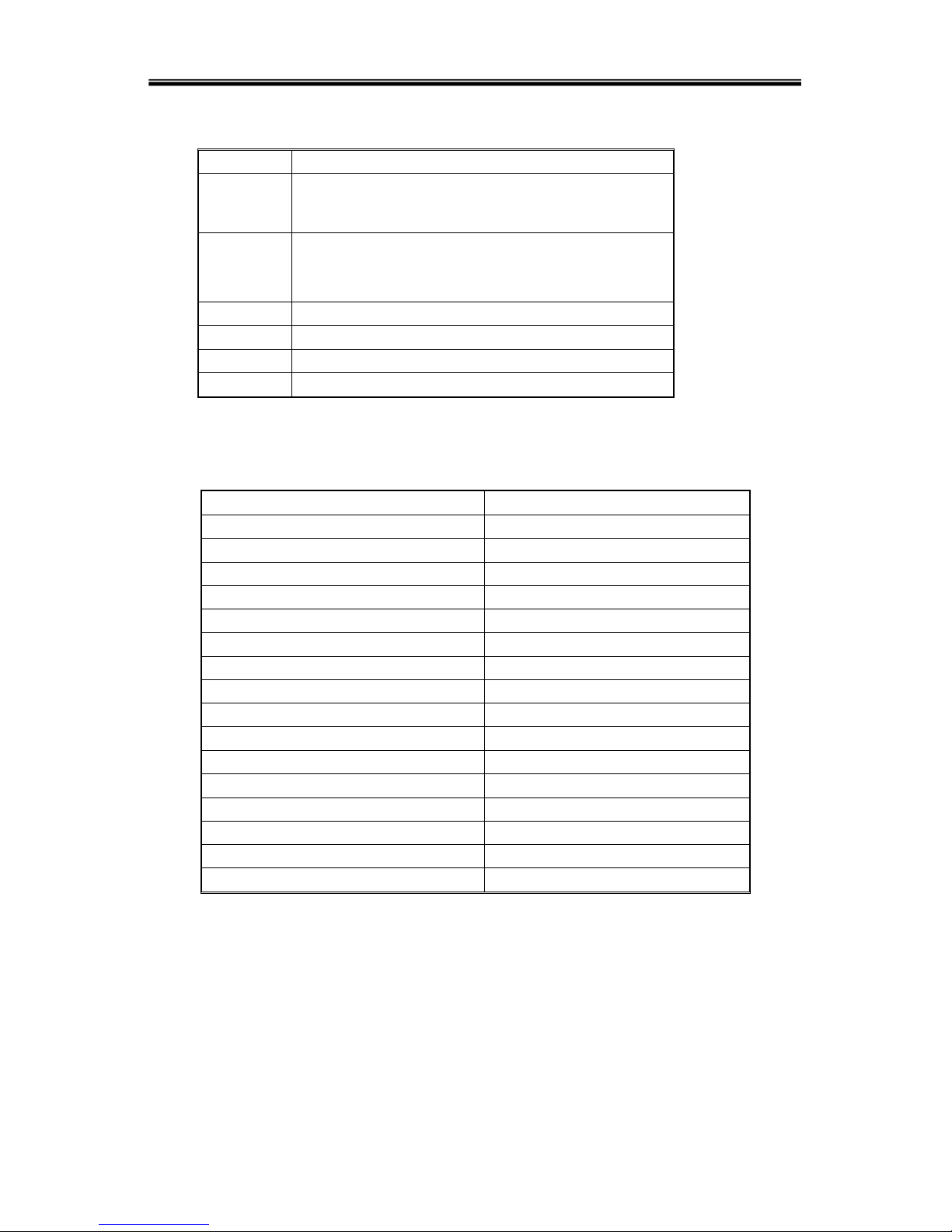

LED indicator definition

1) Fault Indicator(red):On indicates when a fault occurred; Off means no fault

2) Indicator(Green):On means AC is normal, Off means AC is not present,

blinking means voltage is beyond normal range

3) Inverter Indicator(Green):On : when load is powered by inverter, Off : when it

is not working, blinking: when overload

4) Bypass Indicator(Green):On : when UPS is in bypass mode, Off: not in bypass

mode; blinking: when the input is beyond normal range

5) Battery Indicator(Green):On: when UPS is in battery mode, Off : Not in battery

mode; Blinking: when battery voltage is low or battery is not connected

6) Output Indicator(Green):On: when there is output, Off: no output.

LCD display content

1) Running parameters

Input voltage/frequency, output voltage/frequency/current, temperature inside

UPS, battery charging/fully charged, battery voltage.

2)Alarm information ( priority from high to low )

Shutting down, auxiliary power fault, output short circuit, inverter fault, rectifier

fault, over temperature, overload, charger fault, battery fault, ready to shut down,

output fault.

3)Parameter setting

Menu setting, floating /boosting charging setting, battery capacity setting, ID of

parallel UPS, output voltage/frequency level/calibration.

Boosting charging voltage 2.30 to 2.35V per cell floating charging voltage

2.20 to 2.29V per cell

Battery capacity setting includes the above each battery unit, battery

quantity (8 to 10 )*2, parallel group number, low battery voltage alarm value

(EOD ).

Parallel setting

UPS ID setting

LBS setting ( Enable/Disable, Master/Slave)