- 1 -

GB

DE

GB

FR

ES

IT

PT

NL

SE

DK

NO

FI

GR

Table of contents

1 Scope of validity ........................................................................................................................................... 2

1.1 General ............................................................................................................................................................. 2

1.2 Designation and type of the unit ......................................................................................................................... 2

1.3 EC – Declaration of Conformity ............................................................................................................................ 2

2 Information on safe operation ......................................................................................................................... 3

2.1 Explanation of symbols ...................................................................................................................................... 3

2.2 Transport damage .............................................................................................................................................. 3

2.3 Operator’s obligations ........................................................................................................................................ 3

2.4 Unit book ......................................................................................................................................................... 4

2.5 Safety instructions ............................................................................................................................................. 4

3 Use in accordance with specications ............................................................................................................. 4

3.1 Working rules .................................................................................................................................................... 4

4 Scope of delivery ........................................................................................................................................... 5

5 Description of the unit ................................................................................................................................... 5

6 Setting up, installation and putting into operation ............................................................................................ 6

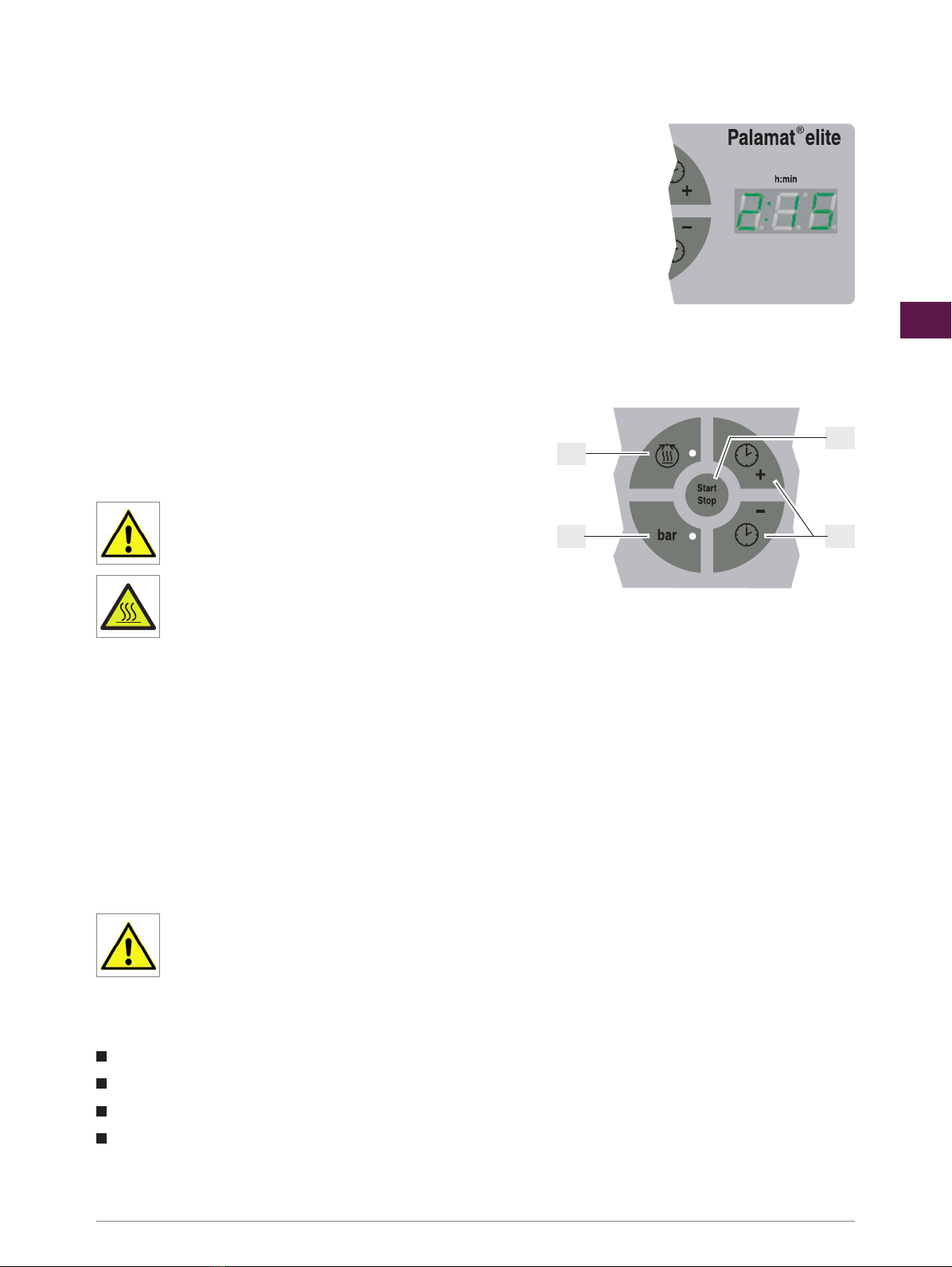

7 Working with the Palamat elite ....................................................................................................................... 7

7.1 Pressure pot ...................................................................................................................................................... 7

7.2 Filling with water ............................................................................................................................................... 8

7.2.1 Overtemperature protection ................................................................................................................................. 8

7.3 Polymerization ................................................................................................................................................... 8

7.3.1 Selecting the temperature stage .......................................................................................................................... 8

7.3.2 Timer Display .................................................................................................................................................... 9

7.3.3 Starting a process .............................................................................................................................................. 9

7.4 Draining the contaminated water ......................................................................................................................... 9

7.5 Putting out of operation ...................................................................................................................................... 9

7.5.1 Disposal of old equipment according to WEEE .................................................................................................... 10

8 Maintenance ............................................................................................................................................... 10

9 Technical data ............................................................................................................................................ 11

10 Information on malfunctions ........................................................................................................................ 11

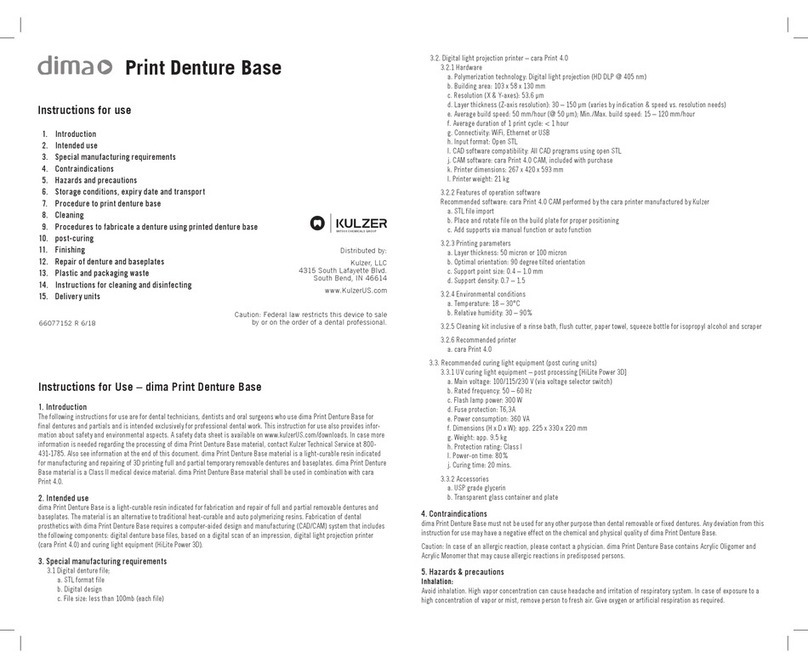

Operating Instructions

Polymerization unit for hot- and cold-curing resins

Dateiname: 02GB_66035693_00_W07501_BA Palamat elite CD_V5_X3

SAP-Nr: Version

66035693 00 HK-Toolbox-Nr:

W07501 Format: Falzmaß:

210 x 280 mm

Projektmanager:

Michael Helken HKG-Version:

V5, 4.AK Datum HKG Freigabe am

16.03.2012 16.03.2012

Druckfarben: Druckverfahren: Offset

C M Y K Sonderfarbe varnish DieCut var.Data

HKG-Layout 66035693_00 BA Palamat elite CD

GB