Table of contents

Table of contents

1 For your safety ................................................................................................................... 5

1.1 ESD sensitive components ............................................................................................................................9

1.2 FCC USA info..................................................................................................................................................9

2 Introduction ..................................................................................................................... 10

2.1 Intended use ...............................................................................................................................................10

2.2 Copyright and liability .................................................................................................................................10

2.3 Warranty .....................................................................................................................................................10

3 Technical data .................................................................................................................. 12

3.1 Electrical connection...................................................................................................................................12

3.2 General data................................................................................................................................................12

3.3 Properties....................................................................................................................................................12

3.4 Server PC minimum requirements..............................................................................................................13

3.5 Web browser minimum requirements .......................................................................................................13

3.6 WLAN topology ...........................................................................................................................................13

4 Transport, installation, storage, disposal .......................................................................... 14

4.1 Scope of delivery.........................................................................................................................................14

4.2 Handling and storage info ...........................................................................................................................14

4.3 Disposal....................................................................................................................................................... 15

5 Commissioning ................................................................................................................. 16

5.1 Prerequisites for commissioning.................................................................................................................16

5.2 Network connection: Work steps and methods .........................................................................................17

5.3 The network ports.......................................................................................................................................18

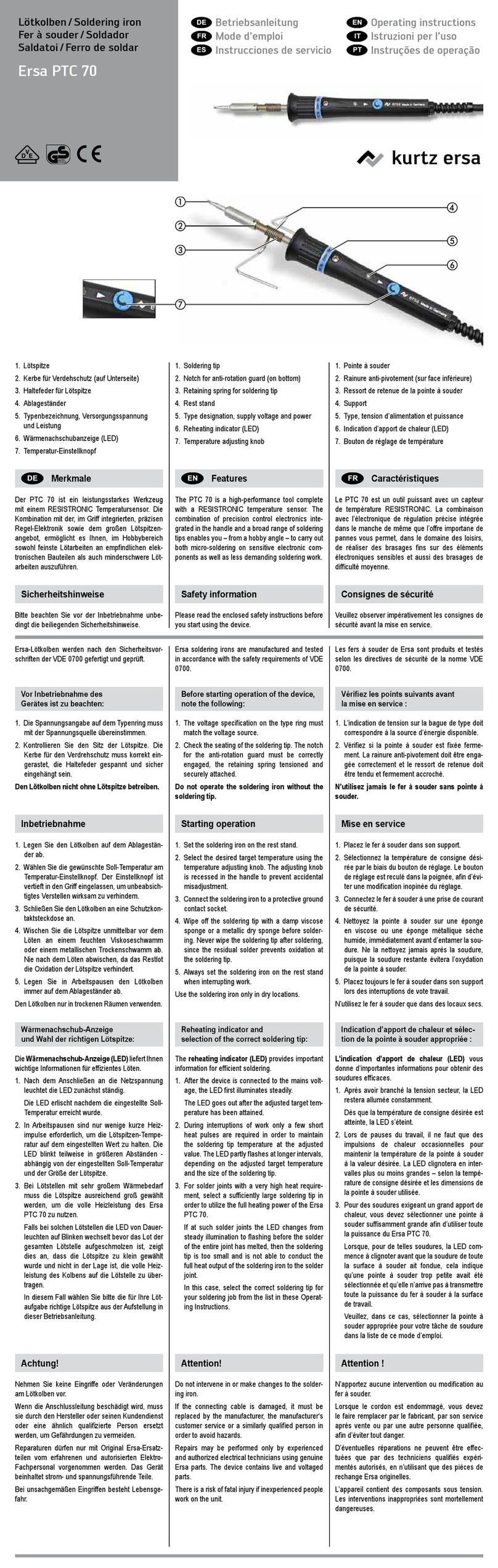

5.4 control elements and connectors ...............................................................................................................19

5.5 Preparing the soldering station to be switched on for the first time..........................................................20

5.6 Switching on the soldering station for the first time ..................................................................................22

5.7 Switching OFF:.............................................................................................................................................23

5.8 Establishing a WLAN connection between the soldering station and a network .......................................24

5.9 Establishing a LAN connection between the soldering station and a network...........................................27

6 Function description......................................................................................................... 30

6.1 Information on the LED indicators ..............................................................................................................30

6.2 Changing soldering tips ...............................................................................................................................31

7 Service and maintenance.................................................................................................. 37

7.1 Error messages and error codes .................................................................................................................37

7.2 Error treatment...........................................................................................................................................38

7.3 Cleaning and Maintenance .........................................................................................................................42

Ersa GmbH 3BA00252-01|Rev. 1 3